Smart Textiles & Textronics

Introduction

Our lives are greatly influenced by textiles, and there has never been a bigger need for intelligent materials like textiles that may easily be combined with technology. Electronic textiles (e-textiles), usually referred to as smart textiles, have electronic components and may perform various tasks.

It was in 1989 in Japan where the phrase "smart material" was first used. Silk thread with a memory effect was the first textile component to be dubbed a "smart textile“. Contrarily, it was generally agreed that the development of intelligent polymeric gels and shape-memory materials in the 1970s and 1960s, respectively, marked the beginning of the era of real smart materials. It wasn't until the late 1990s when intelligent textile materials first appeared on the market.

Collaborations between numerous research fields, including nanotechnology, materials science, fashion design, electronics, and computer engineering, are used to develop smart or intelligent textiles.

The market for smart textiles is growing and holds a lot of promise on a global scale. In developing countries, the market share of e-textile consumption relative to that of traditional fabrics is rising.

The market for innovative textiles is thriving and expanding due to the numerous uses in various industries.

Think about telling your gloves you're too cold, and then having them warm up in response! Or picture yourself as an astronaut floating in space with your suit autonomously adjusting its composition to account for fluctuating space radiation levels (did you know that space radiation exists?). Or perhaps your clothing is changing colors to the beat of the music while you're at a great dance club. At the very least hypothetically, all of these are conceivable.

The creation of woven fabrics that can incorporate cutting-edge technology is the most recent phase of the technological revolution in the twenty-first century. These are what we refer to as "smart textiles," and they are brilliant.

Defining Smart Textiles

A textile is an item created by fusing yarns or threads together to form a cloth. These yarns were initially created using natural fibers from animals or plants. Then, as technology advanced, stronger and more adaptable synthetic fibers were created in laboratories. Today's advancements in digital communications have led to the creation of fabrics made of the same incredibly tiny strands that transmit data through your smartphone. A smart textile is essentially a piece of clothing that has contemporary computer-based technology weaved into it.

What is the purpose? The concept behind smart textiles is that they are adaptable. An automated response, such as turning on the computer fan, is created when, for example, your laptop overheats. That is how smart textiles function. Depending on the programming or kind of technology being utilized, the technology woven into the fabrics will be able to detect changes in the surroundings and react appropriately.

Smart textiles are already starting to be divided into two categories: decorative and performance-improving. Aesthetic smart textiles are those that incorporate lighting and music into the world of textiles for fashion and design objectives. Performance-improving textiles support human activities like jogging by tracking factors like body temperature and modifying the fabric's breathability accordingly.

Since this is a very new field—it just really got going about 2006—it is still debatable in many ways what exactly falls under the umbrella of "smart textiles." The use of thin technology fibers woven into cloth and reactivity to environmental stimuli are the crucial components, though.

Anyone who grew up in the 1980s and 1990s can recall donning stylish "hypercolor" clothing. When exposed to temperature changes, these shirts, sweatshirts, slacks, and headgear displayed various colours of subdued neon tones. Although it was advertised as youth clothing, it was actually the first mass-produced active smart fabrics. To create the mystical effects, thermochromes (in this case, leuco dyes) were added to the cloth.

Types of smart textiles

Textiles that have the ability to sense and respond to environmental cues or stimuli from mechanical, thermal, magnetic, chemical, electrical, or other sources are referred to as smart textiles. They possess the capacity to perceive and react in a preset manner to inputs from the outside world. Smart textiles are defined as those textile items that have the ability to behave differently from typical fabrics and can typically carry out a specific function.

Components in smart textiles

Three components may be present in smart textiles (materials) - Sensors, Actuators, Controlling units

A nerve system for signal detection is provided by the sensors. Certain materials just function as sensors, whereas others function as both sensors and actuators. Actuators respond to the signals and collaborate with the controlling unit to provide the desired output.

Smart Materials

A material or polymer that changes its properties in response to external stimuli or situations is said to be "smart." The key traits and distinctions between conventional, high performance, and smart materials are displayed in the accompanying table.

Classification of smart textiles

Smart textiles are classified into three categories depending on functional activity –

Passive smart textiles

Active smart textiles

Very or ultra smart textiles

Types of smart textiles

Passive smart textiles

Passive smart textiles are the first generation of intelligent textiles that can offer extra functionality when in passive mode without worrying about environmental changes. Good examples of passive smart textiles include conductive fabrics and fabrics with integrated optical fibres. Some examples of passive smart textiles are UV-protective clothing, multilayer composite yarn and textiles, plasma-treated clothing, ceramic-coated textiles, conductive fibres, and fabrics with optical sensors.

Active smart textiles

Active smart textiles are the second generation of smart textiles that feature both actuators and sensors and can adapt their functionality to different agents or surroundings. These include electrically heated suits, shape-memory clothing, chameleonic materials, water- and vapor-permeable (hydrophilic/non-porous) fabrics, heat-storage fabric, thermo-regulated fabric, vapor-absorbing fabric, and fabric with shape memory. Active smart textiles are made of phase-change materials, shape-memory materials, heat-sensitive dyes, etc.

Ultra smart textiles

The third generation of smart textiles, known as very smart textiles, are capable of detecting environmental changes or stimuli and responding accordingly. They represent the pinnacle of smart textiles. These may actively handle potentially fatal events (on the battlefield or in accidents) or maintain high levels of comfort even after drastic environmental changes. These extremely intelligent textiles essentially consist of a brain-like processing unit with cognition, reasoning, and activation abilities. The goal of ultra smart textiles is to integrate complete systems into clothing and accessories in order to make electronic gadgets an actual part of our daily lives. Although the full potential has not yet been fully realized, the advancements made so far can only be described as the beginnings of very intelligent textiles. For example, spacesuits, musical jackets, I-wear, data wear, sports jacket, intelligent bra, smart clothes, wearable computer etc.

The most dynamic degrees of artificial intelligence in textiles are seen in passive smart textiles, which are lifeless but very clever textiles. Given that they lack independent thought, passive textiles might not actually be considered to be very intelligent. However, they carry out specific tasks when in the passive state, hence the name passive smart textiles.

Methods of incorporating smartness into textiles

A sensor, an actuator (for active smart textiles), and a controlling unit are necessary for a textile to behave intelligently (for very smart textiles). Fiber optics, phase-change materials, shape-memory materials, thermochromic dyes, miniature electronic components, etc. might all be included in these components. These elements can be introduced into the substrate at any of the following layers and become an integral part of the textile structure.

Fiber spinning level

Yarn/fabric formation level

Finishing level

Prior to spinning, the active (smart) material can be added to the spinning dope or polymer chips, for example, lyocell fiber can be changed during manufacturing by adding electrically conductive components to create a cellulosic fiber that is electrically conductive. Activators and sensors can also be woven into the structure of the cloth during the weaving process. There are numerous developed active finishes that are applied to the fabric during finishing. During completing, the electronic control units can be synchronized with one another. Smartness-enhancing materials are typically incorporated into the textile substrate using techniques like microencapsulation. However, it is important to choose the right material and approach, taking into account a number of factors.

Making naturally intelligent fibres that can be directly woven into textiles without needing to be further enhanced with intelligence is a problem that lies ahead.

Distinguishing between Smart Textile and Intelligent Textile

Differentiating smart with intelligent textile can be a daunting task. We need to understand the fundamental distinction between intelligent and smart textiles in order to solve this issue. We already know that intelligent textile refers to textile structures that can perceive, react, and respond to environmental conditions and stimuli. Smart textiles interact with the environment. In reality, intelligent textiles are those that can react or be actuated to carry out a task manually according to pre-programmed instructions.

Characteristics of Fibers Used in Smart Textiles

It should have high strength

It should be high chemical and combustion-resistant organic fiber

It should be high modulus organic fiber

It can be Ultra-fine fiber and novelty fiber

It should be high performance inorganic fiber

The smart textile has five features that allow it to perform all of its tasks. They are -

Sensors: They collect environmental data.

Data Processing - When active processing is required, data processing is done.

Actuators: They react to the sensor's resulting function.

Stimulation - It comes from the outside world.

Giving Response- It responds when the actuators are activated.

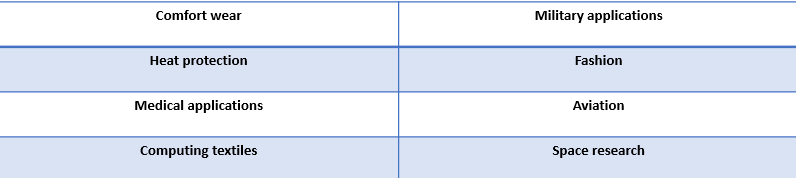

Applications of smart textiles

Applications for smart textiles are many, ranging from everyday use to high technology. We can now go over some of these textiles' significant applications. The following major categories of textiles would be taken into consideration:

It should be noted that a textile that is used in one category may also be used in another. For instance, clothing made of chameleonic textiles—which change color—is discussed. However, they hold a great deal of military significance because uniforms constructed of them can aid in camouflaging to protect the soldier.

Comfort wear: Multilayer composite yarns and textiles

With the use of internal sweat absorbent layers, multilayer composite yarns and textiles show a potential for achieving wear comfort by absorbing perspiration release from the human skin surface. Japan's Toyobo Co. has created a cool and dry three layer composite yarn that comprises of a polyester filament yarn on the outside, a polyester staple yarn in the middle, and a polyester filament yarn in the core. Fine fibres in the centre create more porosity and improve capillary action, which transfers sweat that has been absorbed to the surface of the yarn. To boost its ability to absorb moisture, the coarser polyester yarn (filament) in the yarn inside contains a Y-shaped crossing portion. As a result, moisture is effectively transferred from the fabric's surface that is in contact with the skin to its exterior, which is exposed to the atmosphere. The air currents in the atmosphere then carry away the sweat that has accumulated in the outer layer.

Application of functional finishes to the fabric is another method for achieving body comfort against perspiration release. The human body naturally produces perspiration, which is dissipated by absorbing heat from the body. The body's temperature is kept constant as a result. Sweat evaporation is a normal occurrence that can be accelerated by fabrics treated with Snocool (cool finish). The coating itself uniformly distributes sweat absorption and evaporation, keeping the wearer cool. Additionally, the finish has the ability to reflect light and move moisture from the body to the cloth and then to the atmosphere more quickly than usual. The finish can also be infused with fragrances.

Physiological monitoring (such as heart rate, respiration rate, temperature, activity, and posture), sports training data acquisition, monitoring potential external hazards or hazards involved in handling hazardous materials, and tracking the location and status of soldiers in action are just a few applications where smart and intelligent textiles are used. It is necessary to develop new instrumental analysis techniques and test methodologies in order to evaluate these smart fabrics and apparel. The most recent technology utilized in smart textiles should be taught to fashion and textile designers in sufficient quantities.

Smart textile goods satisfy all requirements for high-added-value technology, enabling a shift to a vibrant high-tech market:

From resource-based towards knowledge-based, From quantity to quality

From mass-produced single-use products to manufactured-on-demand, multi-use and upgradable product services

From ‘material and tangible’ to ‘intangible’ value-added products, processes and services

There are several possible uses for smart textiles with integrated flexible pressure sensors. These items can be used in the medical field to monitor breathing, assess the adequacy of wheelchair cushions, and measure the pressure exerted on the body by clothing, such as hosiery or bandages for varicose veins or leg ulcers. Martial arts has applications in sports science to assess the effect or track the functioning of muscles during training. Additionally, textile-based items in home automation spur more development of novel sensor and controller technologies. Despite the fact that these smart textiles are not yet commercially available due to a number of difficulties integrating textiles and devices and the development of appropriate functional fibre devices, their promising future has drawn a lot of research.

Asbestos and lead abatement, pest control, and the management of hazardous waste are just a few of the uses for non-woven protective clothing. The non-woven materials employed in the fabrication of these garments have a strong barrier function that prevents the passage of dust, liquids, or gases. This problem may be solved and a productive production method for smart textiles may be developed by combining nanomaterials and three-dimensional (3D) printing production techniques. Smart bandages, military safety gear, virtual reality (VR) gloves, wearables with sensor and heat properties, medical applications, automotive, and more can all benefit from this technology. Advanced fabrics created for specialized uses, like extreme sports, eventually make their way into street fashion, where designers are given the freedom to express their creativity by experimenting with these new, evolving materials.

For instance, microfibers were first created for military and space purposes before being employed in clothing, interior materials, and fashion. Eleksen created fabric touchpads that may be incorporated into jackets for more convenient MP3 player operation. Textronics, a different manufacturer of electronic textiles, created materials that can warm, illuminate, conduct, and sense. One of these innovations was a sports bra with heart rate sensors that could wirelessly connect to a heart rate watch. Nano-sized silver, titanium dioxide, and zinc oxide are employed to increase antibacterial characteristics.

Antimicrobial coatings are frequently used on socks to prevent the growth of bacteria, but they are also used on carpets, home furnishings, and apparel in addition to being applied on wound dressings and socks. Self-cleaning surfaces that are super hydrophobic are another breakthrough for these uses. The performance and longevity of ordinary clothing and home furnishings were improved due to its use in resisting spills, repelling and releasing stains, and resisting static. Another was the Philips Lumalive fabric, which had bendable arrays of colored LEDs completely integrated into the fabric. These materials are intended to lift the observer's spirits and have a constructive effect on behavior. The management of health and fitness is one of the most popular uses for smart textiles. Electrical equipment can be used to create smart garments for comfort and entertainment. In recent years, prototypes of textiles with embedded MP3 players, LED and organic LED (OLED) textile screens, GPS technology, and the capacity to answer or reject phone calls have been shown. It has been demonstrated that microphones and speakers may be incorporated into clothing, opening the door to the use of voice recognition technology or gesture-activated technologies, which enable commands to be delivered to the clothing to carry out specific activities.

The Google Jacquard technology has been included into the Levi's Commuter Trucker Jacket. This technology communicates with smartphones. Without actually picking up the smartphone, the wearer may manage calls, texts, GPS, and music with this jacket (Figure 2). The jacket has the capacity to read aloud messages and offers vibration and LED light choices for alert communication. On the jacket's sleeve is a replaceable snaptag that can be used to recognize motions to operate the gadgetry.

Smart textiles are a major concern, particularly in industrial and laboratory environments. Making the cloth anti-static is one way to improve worker safety. These clever anti-static materials can be used to create durable, long-lasting clothing. By using its built-in electronic article surveillance technology to be able to identify the precise number of products that have been purchased, radio frequency identification brand label technology, which is sewn onto clothing products that are resistant to hand washing and dry cleaning, discourages theft and streamlines checkout and return procedures.

Aromatherapy is one of the less popular uses of smart textiles in personal health. A prevalent factor in the production of smart textiles is temperature control. The Under Armour smart shoe can be linked to a smartphone app that measures information including pace, cadence, stride length, and distance travelled. Wearable smart textiles have a plethora of medical uses in the modern environment. Temperature and humidity sensors are available to assess the patient's status. Around the world, numerous colleges are attempting to create clothing that increases personal comfort levels, reduces the need for a lot of heating and cooling, and also implements control systems by creating wireless charging systems. Wearable shirts with fabric electrodes for ECG monitoring have been successfully implanted, enabling long-term patient monitoring. Breathing signals have been gathered using piezo resistive fabric sensors stitched into shirts.

Sensing devices that track the volume and pattern of movement in patients undergoing rehabilitation can be used to evaluate the efficacy of prosthesis. For instance, it is possible to examine a prosthetic arm's movement either directly or in relation to the patient's other arm. Other applications of smart technology include maintaining body temperature, changing color in response to environmental stimuli, developing synthetic ligaments and joints, measuring immune system resistance in sick patients through clothing, signaling one's location through clothing, cooling the body in extremely hot conditions, cooling products like laptop mats, charging electronics, self-cleaning clothing, odor-free socks, reinforcing concrete, etc. Once more, the majority of these fabrics are machine washable, however some have a short shelf life.

Smart textiles changing the world

Gore-Tex Smart Fabric

The first smart textile fabric, Gore-Tex, was created in 1978 by the Gore Company. A new era of smart clothes was inaugurated by this application of smart fabrics. It has the capacity to allow moisture to move in a single direction. Ten billion pores are concentrated in one square inch of the fabric membrane. Simply put, pore density refers to the size of individual pores on the microscopic scale, where a water droplet is 20 million times larger than individual pores and a water vapor molecule is 700 times larger. As a result, it permits the body to release water vapor and sweat. This quality makes it breathable, windproof, and waterproof. Gore-Tex Smart Fabric also deters insects from harming the membrane.

Wearable Motherboard

In order to create a wearable motherboard, the US Navy launched Georgia Tech in 1996. Georgia Tech is a cutting-edge institution that merges electronics. Georgia Tech Wearable Motherboard recently made its commercial debut as a Smart shirt. Military textiles have seen dramatic modifications as a result of the wearable motherboard's use in smart textile applications. That was made specifically for use in combat. Military uniforms with clever camouflage use optical fibres that can see bullet wounds. Special sensors may interconnect to track vital indicators under fighting conditions. Medical sensing devices are affixed to the body in this computerized clothing. It thus produces a flexible motherboard. The motherboard in question is braided. As a result, special threads like plastic optical fibres and others are incorporated into the GTWM's construction. The GTWM accurately pinpoints the precise site of physical harm. then transmits the data in milliseconds to identify those who want emergency assistance. As a result, in a dangerous battle situation, saving lives is simple. Depending on the needs of the wearer, different types of sensors are utilized in GTWM clothing. It can be altered to suit each user's preferences. such instance smart clothing for firefighters that has a sensor to track levels of both dangerous gases and oxygen. The smart textiles shirt is applicable in a wide range of industries. Currently, Sensatex Company produces textile products for the commercial market that are used for medical, disease, infant, sporting, and military purposes.

Smart Running Shoes

In 2004, Adidas released the first pair of smart shoes on the market. A sensor, microprocessor, electric motor, and the real smart electronic textile material make up the smart shoes. Its cushioning system is movable. Depending on the surface they are running or walking on. The 20 MHz processors in this smart shoe sensor allow it to read 20,000 readings per second. These assist in performing 10,000 calculations per second. The tension of a metal rope that helps the user can be adjusted by a little motor in the heel. It also includes a suitable system for shock absorption to help the runners.

The Nike brand recently produced the newest smart socks and shoes. This makes extensive use of specialized sensors to keep tabs on the interactive actions of the wearers. It is capable of information communication with Android devices. The wearer can receive statistics on running conditions, speed, total distance run, and other factors to his mobile device via the Android applications. Additionally, it has the ability to send data that will automatically upload and post a status update on Facebook. Numerous other scientists experiment with smart shoes and shocks. We will soon see a revolution in smart clothes thanks to partnerships between the application of smart textiles with smart shock and shoes.

Biosensor Smart Underwear

Direct screen-printing of biological sensors onto clothing was created by Nano-bioelectronics researchers at the lab at the University of California, San Diego. By printing sensors on the elastic bands in the underwear, the researchers make sure the sensors keep tight contact with the skin. NADH and hydrogen peroxide enzymes are detected by the elastic band sensing electrodes (H2O2). These cases are connected to a number of biological procedures. These sensors were able to indicate whether the wearer's normal actions, such as flexing and stretching, would not put too much strain on them. A new realm of potential uses for the field of smart textiles has been made possible by biosensor on woman's smart underwear.

Smart Bra

One of the best examples of intelligent clothing and the most practical use of intelligent textiles is the intelligent bra. It enhances the women's overall comfort while wearing bras. A smart bra was created by Australians Wallace et al. at the University of Wollongong. In response to breast movement, this intelligent bra may alter its characteristics. As a result, it better supports women's employment activities. Modern smartphone applications allow for the monitoring of smart bras. By hardening and relaxing its cups and tightening and loosening its straps to limit breast mobility, the Smart bra effectively prevents breast soreness and sag. Typically, conductive polymer coated fabrics are used in Smart manufacturing. The elastic properties of the smart fabric can be altered in response to information about the amount of stress they are experiencing. As a result, it has the ability to stiffen or stiffen its cups immediately in response to excessive movement.

Motion Detecting Smart Pants

A pair of pants was created by the research teams at Virginia Polytechnic Institute and State University in Blacksburg as an illustration of smart fabric definition. This smart pant's unique feature is that the wearer's movement, rotation, speed, and location can all be detected by the smart fabric. By transmitting a wireless signal, the developed smart fabric recorded specific information about the movement to a cloud server. Motion-detecting clothing is motivating individuals today to further the use of smart textiles in fashion.

NASA AeroGel Jacket

The Aerogel component, created by NASA, is the greatest insulating material for smart clothing. The aerospace textile business is revolutionized by this use of smart fabrics. since it is quite heavy, has a low density, and frequently appears translucent. Solid smoke is a common name for aerogels. It can produce textile blankets, beads, thin sheets, and moulded pieces thanks to its adaptable nature. As a result, the goods are not big and heavy.

Smart Baby Vest

At ITV Denkendorf, researchers created a unique vest for infants. The smart baby vest is fitted with sensors and microchips. It might involve ongoing observation of important matters. include the heart, lungs, and body temperature. As a result, heart and circulation problems can be quickly identified by doctors. It has already been used to stop cot death in infants. In addition, it is applied to other adult patients who are in life-threatening circumstances in order to save a life. The sensors on the Smart Infant Vest are positioned so that the baby is not bothered. One of the most innovative uses of smart textiles in the medical field is this one.

Smart Fire Fighter Jacket

The clever firefighter's jacket was created by VIKING in 2009. The internal and outside coat layers are integrated, as well as heat sensors. in order to control the high temperature close to the firefighter on the inside of the coat that is close to the body. Two LED screens are attached to the smart jacket sensors for firefighters. Both are located on the back and the sleeve, respectively. Critical situations are indicated on the display at the upper left shoulder. Additionally, the LED display's lower sleeve displays dangerous heat levels. A power source for the intelligent firefighting jacket is provided by rechargeable and detachable batteries. Microelectronics chips in the smart firefighter gear assist in indicating the dangerous status on the LED display. Different danger alarms were displayed to firemen by LEDs depending on the temperature. Firefighters must simultaneously make the right judgement and be aware of the situation's reality for this use of smart fabrics to be successful.

Smart Textiles in Fashion Industry

Smart fabrics are increasingly being used in the fashion business thanks to people's modern, tech-friendly lifestyles. People embrace a variety of other smart apparel only for the sake of fashion to be clever. In this area of smart textile in fashion, fast fashion and intelligence collaborate. In 2000, the ICD+ jacket was unveiled by Philips and Levi Strauss. That combines a mobile phone that can be managed remotely and an MP3 player. The first wearable and machine-washable smart jacket was the ICD+ jacket. Canesis introduced electrically heated wool socks in 2004–2005. The conductive yarns and wool used in the production of the smart socks are designed with trekking in mind. For use on individuals who have poor circulation or in extremely cold environments, battery-powered shocks are ideal. The amount of heat produced by smart shocks is the same as the rate of heat loss. This invention completely transforms the sportswear industry's use of smart textiles. Many commercially available pieces of clothing are made with the help of smart textile technologies. The fashion industry's adoption of smart textiles has misdirected their potential range of uses.

Way forward

One of the five fundamental necessities of humans is textile. Textiles have only ever been used for clothing from antiquity. That included domestic and home uses. However, the technical textile market segments have developed and are now extremely diverse. perhaps the most exciting development in the textile business is the use of smart fabrics. In the late 1980s, the global textile industry first encountered smart textiles. But since then, the use of smart fabrics has multiplied 1000-fold. We now have self-cleaning carpets, fabrics that respond to their environment, temperature-regulating suits, and shoes thanks to the perfect use of smart textiles. The use of smart textiles has had an impact on all major textile industries. They can be used for everything from sportswear to military uniforms, protective gear, bio-medical textile, and more.

The uses for intelligent fabrics are incredibly diverse. It used to sound like science fiction. But now, smart textiles have a huge impact on how we live. It is feasible to be a traditional textile in the very technologically oriented textile industry thanks to the application of smart textiles.

Intellectual Property – A stich in time

Over the past fifty years, advancements in the textile and fabric business have changed its three primary areas, which are apparel, home goods, and technical textiles. The women's and active wear clothing industries were irrevocably altered by lycra. Firefighters all over the world have been saved by cotton overalls treated with the chemical flame retardant Proban and hoods made of the flame-resistant fabric Nomex. Additionally, the introduction of new fabric has improved the strength, comfort, and appeal of furniture. The importance of intellectual capital to the textile and fabric industry cannot be understated. However, many small and medium-sized businesses (SMEs) in the sector give little thought—if any—to safeguarding their intellectual property. Innovation and unique creative expressions are the main sources of competitive advantage for all organizations in the present business environment. In order to decide which of these valuable intangible assets should be safeguarded and capitalized on using the instruments of the intellectual property (IP) system, business managers must quickly identify them, ascertain their business importance, and do cost-benefit evaluations.

Utilizing IP rights strategically can help all types of textile firms compete more effectively, decrease risk, and forge commercial alliances.

PATENTS

One approach to distinguish a textile manufacturer from the competitors is through technical innovation, which is protected by patents. A company's technological superiority can be seen in its patent portfolio, which can demonstrate that it has created new fabrics that do not wrinkle, are softer, more resistant to the elements, have more elasticity, etc. A patent portfolio like this may help to draw in investors or business partners.

Novozymes, a biotech business based in Denmark that specializes in enzymes and microorganisms, was the first to employ enzymes to cure fabrics. Despite not having previously worked in the textile sector, the company created and patent a method in 1987 for treating "stone washed" denim jeans. Based on an enzyme called cellulase, this method gives denim a worn appearance by removing some of the indigo color. Within three years, Novozymes' cellulase was being used by the majority of the denim finishing business under license. The technology developed by Novozymes to enhance production processes and fabric finishing is now licensed internationally. The company maintains a proactive licensing approach to maximize royalty revenue from its more than 4,200 active patents and patent applications.

Suberis, a cutting-edge cork fabric created by the Italian business Grindi Srl, is reported to be as smooth as velvet, as light as silk, washable, unscratchable, stain-resistant, waterproof, and fireproof. Grindi submitted a worldwide patent application under the Patent Cooperation Treaty (PCT) in 1998 to safeguard its distinctive product across a wide range of nations after testing and codifying the procedure. Numerous more products, including athletics, footwear, and clothes, are made with the Suberis fabric.

The Procter & Gamble Company gave North Carolina State University 37 patents and patent applications from a significant development in the technology of textile manufacture in 2002. By using cationic peroxide bleach activators, the method may be able to reduce the temperatures—and hence the cost—at which textiles are produced. In comparison to the existing high temperature bleaching method, the use of cationic activators produces far softer bleaching conditions and allows cotton to maintain more of its fibre strength. The ability of the invention to effectively pre-process raw cotton bleaching at room temperature is promising. In addition, a wider variety of fabrics may be able to be treated with a permanent press finish if cationic peroxide activators are successfully developed and put to use. This innovation, which still has to be developed and tested, is anticipated to have a big economic impact on the creation of new kinds of durable apparel as well as textiles. If the technology is successfully developed and marketed, NC State University will reap all future profits as the sole new proprietors.

In addition to determining whether an invention is patentable, timely and efficient patent database searches can yield very useful data and intelligence on the following topics:

The R&D activities of current and future competitors

Current trends in a particular technology field

Technologies for licensing

Potential suppliers, business partners, or sources of researchers

Potential market niches at home and abroad

Patents of others to ensure that products do not infringe upon them

Please feel free to reach out to one of our subject matter experts at info@effectualservices.com

to explore, how we can help you & make the world a better place to live in !!!

Effectual’s SMART TEXTILES TECHNOLOGY RESEARCH FRAMEWORK is a deep dive into this ecosystem and shall help you understand the intricacies of this nascent innovative domain with insights backed with credible data sources. Some ways we can help include, but not limited to - Performing any previous art or freedom to operate searches to help you better grasp the environment surrounding your invention or business endeavors. If certain methods of IP protection are more appropriate for your technological or business goals, we can help you strategize effectively to plan for future & in making continuous innovation a part of your working model

About Effectual Services

Effectual Services is an award-winning Intellectual Property (IP) management advisory & consulting firm offering IP intelligence to Fortune 500 companies, law firms, research institutes and universities, and venture capital firms/PE firms, globally.

Through research & intelligence we help our clients in taking critical business decisions backed with credible data sources, which in turn helps them achieve their organisational goals, foster innovation and achieve milestones within timelines while optimising costs.

Our Services

Solutions Driving Innovation & Intelligence

Enabling Fortune 500's, R&D Giants, Law firms, Universities, Research institutes & SME's Around The Globe Gather Intelligence That

Protects and Nurtures Innovation Through a Team of 250+ Techno Legal Professionals.