Conversion of municipal solid wastes into Fuel/Gas for Domestic use or Vehicle: Part 3

Municipal solid waste conversion into fuel or gas offers a sustainable solution for energy needs in domestic and vehicular applications. Leading companies like Suez SA pioneer pyrolysis processes, such as EP3260181B1, transforming plastic wastes into diesel via thermal cracking at 380-450°C. Doosan, Veolia, and Mitsubishi advance grate combustion, biogas recovery, and catalytic cracking, reducing landfill reliance while producing renewable electricity, heat, and biofuels from MSW, sewage sludge, and non-recyclables. These innovations, including Créteil's waste-to-energy plant and Veolia's SRF production, align with global green economy goals, cutting CO2 emissions and fostering circular resource use.

Suez SA

About Company

Suez SA (Suez) is a company that transform residual waste into electricity and heat, helping to meet local renewable energy needs, whether industrial or domestic. The Suez supports characterisation of residual waste in terms of composition, but also evolution, study and engineering, choice of energy source and sizing of the sector, construction of units, operation and optimisation of your installation over time, CO2 capture and management.

The Suez offers biogas recovery methods adapted to local contexts: proximity to natural gas transmission or distribution networks, local energy needs (residential, collective, tertiary, industrial), presence of natural gas refuelling stations for vehicles, etc.

To produce and transport the steam to the Haguenau production site, SUEZ concluded a 15-year partnership relative to the supply of sustainable energy with MARS Wrigley France, ENGIE and the SMITOM in charge of processing the household waste from Haguenau-Saverne.

The Créteil waste-to-energy plant

In December 2018 the Val-de-Marne urban mixed waste treatment agency (SMITDUVM) entrusted the concession to upgrade and operate the Créteil waste-to-energy recovery unit to SUEZ – in partnership with TIRU, a Dalkia subsidiary – for a period of 20 years via the dedicated company Valo’Marne. The contract involves. transforming carbon into oxygen, producing hydrogen for vehicles, green electricity and heat for the district heating network and growing tomatoes in greenhouses while creating local jobs.

These are the words of Laurent Cathala, mayor of Créteil, expressing his pride in a project he describes as particularly “innovative and bold”. The first installations will be operational by 2023. Processing capacity will be expanded to recover even more waste – 345,000 tonnes a year – and convert it into green electricity at the same price as normal electricity for the SMITDUVM member municipalities, or into heat for Créteil residents. Not forgetting the installation of a carbon sink that uses microalgae to capture CO2 and convert it into biomethane for use in the gas network; hydrogenthe reduction of NOx emissions to less than 50 mg/Nm3 a production to fuel clean vehicles, a first in France; nd the use of river transport to limit truck journeys, with a transfer quay in Champigny-sur-Marne.

Conversion of municipal solid wastes into Fuel/Gas for Domestic use or Vehicle

Patents Related to Conversion of Plastic Wastes into Fuel

EP3260181B1

Title: Process for conversion of plastics into fuel

Publication: 2019-09-18

Coverage: CN,CA,WO,US,AU,SG

Assignee: Suez

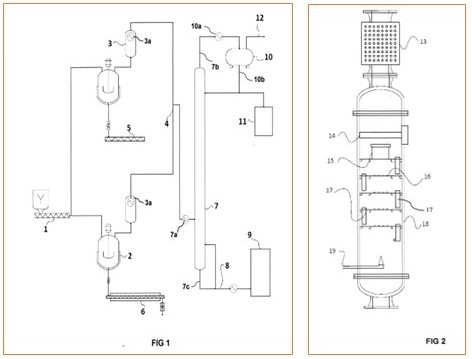

- The present invention relates to processes for converting plastic materials, in particular waste plastic materials, into liquid hydrocarbons, particularly diesel fuels.

- In the pyrolysis chamber (2), the plastic material is heated up to a temperature between 380°C and 450°C in a nitrogen purged system under agitation, and this temperature is maintained during the pyrolysis. The melted plastic material is thermally cracked into pyrolysis gases and char formation occurs simultaneously in the pyrolysis chamber.

- The flash distillation column is a column with few internal elements, where the saturated liquid gas mixture fed after condensation in condenser (7a) undergoes pressure reduction. The flash distillation column is typically operated at a pressure close to atmospheric pressure. It contains very few internal elements, thus reducing fouling risks. and connected to a recirculation loop for said liquid, preferential starting from the top, the flash column may contain a recirculation device for liquid hydrocarbons from the reflux drum (10), a liquid distribution tray for said recirculated liquid, a minimum layer of packing elements to help prevent liquid entrainment, a light oil tray for extracting liquid hydrocarbon positioned in the middle, preferentially in the top third the column, y below the extraction level, said recirculation equipped with spray nozzle to spray recirculated liquid, and, in the lower part, and a recirculation loop for heavy hydrocarbons obtained at the bottom of the column, equipped as well with spray nozzle to spray recirculated heavy hydrocarbons.

- Heavy fractions (diesel oil) are recovered at the bottom of the flash distillation vessel in a diesel tank (9). Further separation step may be implemented on said diesel oil, for example solid separation, tar separation, and optionally a vacuum distillation step to remove lighter fraction and correct flash point.

Doosan

About Company

Doosan Lentjes is one of the world’s leading specialists in grate combustion. Doosan reciprocating grate features adjustable grate bars that move back and forth between fixed bars. Three sections are installed and the width of the grate is tailored to suit the moisture content, calorific value and composition of the waste. With low wear and tear and a high thermal load-bearing capacity of roughly 1MW/m2, Doosan water-cooled grate is suitable for the incineration of high-calorific waste, such as, solid recovered fuel. The roller grate consists of six graded cylindrical rolls switched in a row, the revolutions of which may be regulated to adapt to different waste incineration behaviour. The roller surfaces are cooled continuously by the primary air, which also enables higher calorific waste to be fed in.

Commenting on the project, Gerhard Lohe, Product Director Waste-to-Energy at Doosan Lentjes, says: “This project is the first waste to energy plant that DHIC and Doosan Lentjes are executing together. It proves that international EPC experience in large-scale plant construction projects as well as a rich heritage and competence in modern WtE technology is a strong combination of capabilities that meets the demands of the industry.

The new plant, scheduled to be completed in 2023, will be capable of processing up to 110,000 tonnes of refused derived fuel (RDF) produced by the citizens of the greater Olsztyn area.

Poland’s waste management infrastructure

After completion, which is expected in 2024, 265,200 tonnes of municipal solid waste will be thermally treated per year in the Polish capital. Our proven air-cooled reciprocating grate technology will ensure highest operational flexibility with regard to changing waste qualities or compositions and thus guarantees long-term disposal security. The new plant will make a significant contribution to meeting European requirements for sustainable waste management.

In executing the project, we are drawing on well-founded experience in the Polish market for waste incineration: not only are we currently building the new thermal waste treatment plant in Olsztyn as the responsible general contractor. We also successfully supplied grate and boiler technology for the WtE plant in Krakow about eight years ago, which has been reliably thermally treating the residual waste of more than 750,000 inhabitants of the region ever since.

Conversion of municipal solid wastes into Fuel/Gas for Domestic use or Vehicle

Patents Related to Conversion of Sewage and Waste Water into Fuel

KR101685667B1

Title: Manufacturing system for solid fuel using sludge

Publication: 2016-12-20

Coverage: KR

Assignees: Doosan Pocheon Energy Co Ltd, Irea Env Ind Co Ltd

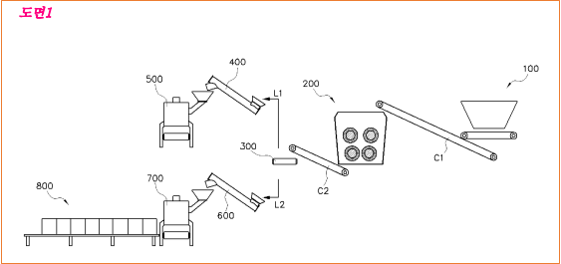

- Provided is a pellet production system using sewage and waste water sludge that can realize environmentally friendly resource circulation by recycling sewage and waste water sludge to pellet fuel.

- Referring to FIG. 1, the pellet production system using sewage and waste water sludge according to the present disclosure includes a hopper 100 for inputting sewage and waste water sludge, wood flour, waste plastic, and solidifying agent.

- Here, the present invention realizes environmentally friendly resource circulation by recycling sewage and waste water sludge into pellet fuel, and mixes wood flour and waste plastic into the sewage and waste water sludge through a solidifying agent to prepare pellet fuel, Preferably, 40 to 70 % by weight of sewage and waste water sludge, 20 to 40 % by weight of waste plastic, and 10 to 20 % by weight of waste plastic are aggregated with a solidifying agent to produce a pellet fuel.

- Next, a first conveyer belt (C1) for conveying sewage and waste water sludge, wood flour, waste plastic and solidifying agent from the hopper (100). That is, the first conveyor belt C1 performs the role of transferring sewage and waste water sludge, wood flour, waste plastic, and solidifying agent supplied through the hopper 100 in a known configuration to the mixer 200 described below for mixing.

- Next, a mixer 200 is configured to input sewage and waste water sludge, wood flour, waste plastic, and solidifying agent conveyed by the first conveyor belt C1, and mix the input sewage and waste water sludge, wood flour, waste plastic, and solidifying agent while conveying through the screw 220 to prepare a sludge mixture. That is, the mixer 200 is an apparatus for uniformly stirring and mixing sewage and waste water sludge, wood flour, waste plastic, and solidifying agent inputted through the first conveyor belt C1, and has a structure in which the inputted sewage and waste water sludge, wood flour, waste plastic, and solidifying agent are discharged through an outlet while continuously mixing therein.

Veolia

About Company

Non-recyclable non-hazardous waste is transported to incineration plants or landfills. The incineration process produces energy in the form of steam which can either supply district or industrial heating networks, or be converted into electricity using turbines.

The electricity generated is used to power the national distribution network. Veolia captures the gas generated by the fermentation of organic waste in its landfills. This biogas can be directly delivered to a distribution network, used to produce electricity through turbines or engines, or used as fuel for vehicles.

Veolia manages more than 90 Waste-to-Energy facilities in the world to treat municipal solid waste while creating renewable energy. Considering the low heat value of municipal solid waste, Veolia has the expertise to adapt all the existing technologies to the different types of waste for an optimal heat and electricity generation.

Waste volume reduction, preserving energy and limiting greenhouse gas emissions are the main benefits of Veolia’s effective solutions: Incineration reduces waste to 10% of its original volume and provides an alternative to fossil fuels, creating renewable energy or heat for district heating.

We are supporting South Korea in its goal of becoming one of the world’s top five 'green economies.’ Since 2007, we have operated a plastic waste recycling facility in Yeoju, Gyeonggi Province. We collect, process and recycle the waste into solid recovered fuel (SRF). Today, we process nearly 70,000 metric tons of industrial waste, from which 60,000 metric tons of SRF is produced.

Conversion of municipal solid wastes into Fuel/Gas for Domestic use or Vehicle

Patents Related to Conversion of Waste Steam into Solid Cake that Use as a Fuel

CN1938068A

Title: System and method for recovering oil from a waste stream

Publication: 2007-03-28

Coverage: CN, WO, JP

Assignees: Veolia

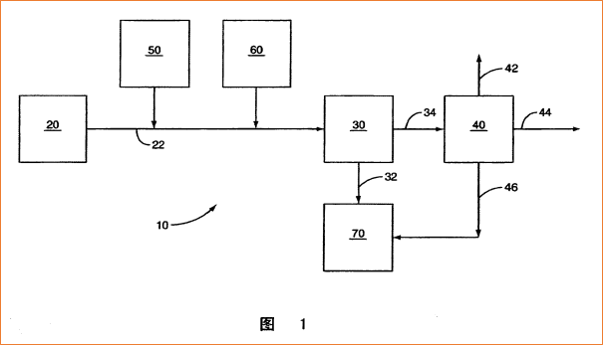

- The present invention relates to systems and methods for recovering oil from waste streams or other oil-containing streams, and in particular, to recovering oil from emulsified streams by destabilizing the emulsion by chemical and/or mechanical methods.

- In accordance with one or more embodiments, the present invention provides a method for recovering oil from an emulsified stream. The method may include the steps of: the method includes destabilizing the emulsified stream, separating the destabilized emulsified stream to produce a thickened emulsified stream and an aqueous stream, and separating the thickened emulsified stream to produce a second aqueous stream, an oil-rich stream, and a solids cake.

- The oil-rich component stream 42 can optionally be sent to a unit operation (not shown) of a chemical plant. For example, the rich stream may be sent to one or more refinery unit operations that may derive from or utilize the hydrocarbon values associated with the rich stream.

- The solid filter cake 44 may optionally be disposed ofus or transported to a coking facility, or used as a fuel in one or more industrial applications, examples of which include, but are not limited to, fuels in cement processing operations (not shown).

Mitsubishi

About Company

Mitsubishi Power Europe has been developing thermal waste treatment technologies for more than 50 year and offers integrated solutions worldwide that are optimally machted and tailormade to meet our customers' individual requirements for solid waste materials up to 140 MWth and steam parameters up to 500°C - 100 bar.

The Waste-to-Energy solutions from Mitsubishi Power Europe help to replace fossil fuels and to reduce CO2-emissions while minimizing disposal limitations of organic residues.

N+P Group and Mitsubishi Power Europe to collaborate on waste-derived alternative fuel use in existing coal-fired power stations.

The Mitsubishi Chemical Group (MCG Group) is promoting various kinds of chemical recycling methods as concrete solutions to the problem of plastic waste. We'll explain the chemical recycling method of plastic-to-oil conversion, jointly pursued by the MCG Group and ENEOS Corporation toward a circular economy, along with its advantages and challenges, and the potential for new resource recycling pathways.

Reusing waste plastics as chemical raw materials could lead to a significant reduction in fossil fuel consumption. While oil conversion helps prevent resource depletion, one challenge is that it requires a large amount of energy to induce the oil conversion reaction (via pyrolysis) even though it is energy efficient. However, comparing over the entire lifecycle, this process emits less GHG than incinerating waste plastics.*2 Plastic-to-oil conversion is a promising approach to recycling waste plastics, through further technological development is required to improve energy efficiency.

Mitsubishi Heavy Industries Environmental & Chemical Engineering Co., Ltd. (MHIEC) has received an order from Yokohama City, Japan, to rebuild the Hodogaya Plant waste-to-energy facility.

Mitsubishi to build $251m waste-to-energy plant in Japan. Owarihokubu Waste Disposal Association provides waste treatment for four municipalities in the northern Aichi region, comprising Inuyama City, Konan City, Oguchi Town, and Fuso Town in Niwa County.

Conversion of municipal solid wastes into Fuel/Gas for Domestic use or Vehicle

Patents Related to Conversion of Plastic Wastes into Fuel for Vehicle

JPH10310778A

Title: Purification of oil made from waste plastic and purified fraction

Publication: 1998-11-24

Coverage: JP

Assignee: Mitsubishi Oil Co

- An object of the present invention is to solve the problems of the conventional technology described above, and to provide a method for purifying a waste plastic oil product into a high-quality fuel oil for automobiles at low cost, and a purified fraction.

- As a result of diligent research to solve the problems described above, the present inventors completed a purification method by which dienes, chlorine content, and oxygen content in a waste plastic oil-based produced oil are removed using a fluid catalytic cracking apparatus that does not use hydrogen.

- That is, the aforementioned problems of the present invention are achieved by 1 . a purification method for a waste plastic oil product oil, the method comprising treating a waste plastic oil product oil containing dienes, chlorine content, and oxygen content in a fluid catalytic cracking apparatus; 2 . a method of purifying a waste plastic oil product oil by mixing 1 to 100 vol.% of a waste plastic oil product oil as a raw material oil for a fluid catalytic cracking apparatus, A petroleum fraction having a boiling point of 250 °C or higher is used, and the petroleum fraction is treated with a fluid catalytic cracking apparatus. 3 . the petroleum fraction has a diene content in terms of diene value of about 0.1 to 5.0gI2/100g, a chlorine content by a fluid catalytic cracking apparatus; 4 . the purification method described in 1 or 2, wherein the fluid catalytic cracking apparatus has a configuration having a riser-type reactor, a catalyst/product oil separator, and a catalyst regeneration column; The purification method of the waste plasticized product oil described in 2 or 3, 5 . a gasoline fraction, a light oil fraction, or a column bottom oil fraction obtained by fractionating the product oil obtained by any one of the purification methods described in 1 to 4, and 6 . an automobile fuel containing the gasoline fraction or the light oil fraction as a main component described in claim 5 as a main component.

- The present invention is particularly useful from the perspective of removing dienes, chlorine components, and oxygen components in the produced oil of waste plastics by subjecting the produced oil of waste plastics to catalytic cracking reaction using a solid acid catalyst, purifying the oil of waste plastics into a high-quality automobile fuel, and reducing driving costs because hydrogen is not used.

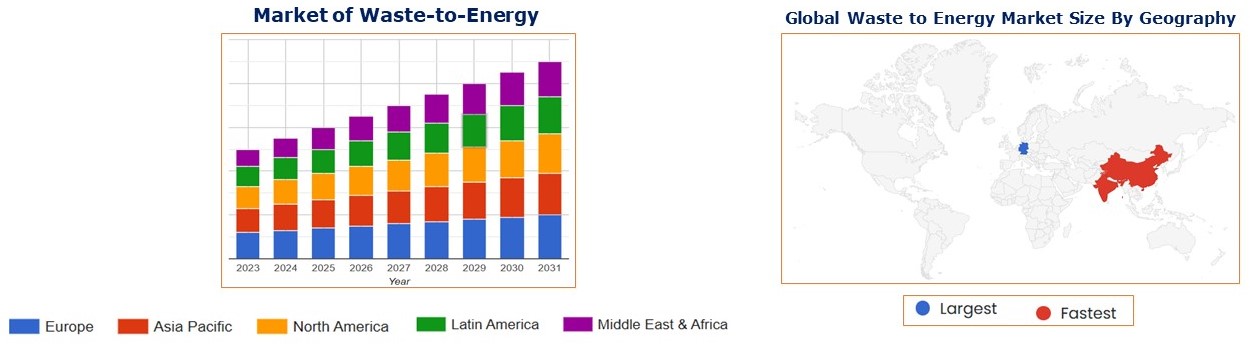

Market Insights

The government in The global waste-to-energy market is segmented into Technology, Waste type, and Region. Based on Technology, the market is bifurcated into Physical Technology, Thermal Technology (Incineration/Combustion, Pyrolysis and Thermal Gasification, Plasma-arc Gasification), and Biological Technology (Methane Capture/Landfill Gas, Biogas Plants/Anaerobic Digestion, Fermentation). In terms of waste type, the market is segmented into Municipal Solid Waste (MSW), Industrial Waste, Agricultural Waste, and Others. Region wise, the market is segmented into North America, Europe, Asia Pacific, Latin America, Middle East and Africa.

Recent Development in waste-to-energy conversion

Waste to energy can be achieved by utilization of chemical (esterification), bio-chemical or thermo-chemical technologies. The use of these technologies is decided based on numerous factors, which include the composition and type of waste, calorific value, and the final energy form. The energy generated is utilized for applications such as electricity and heat generation, which is predominantly achieved by incineration. Transport fuels such as ethanol, bio-diesel, and bio-jet fuel are produced by processing waste. Increased blending of ethanol to gasoline is expected to bolster market growth for ethanol generation.

Waste-to-energy plants burn municipal solid waste (MSW), often called garbage or trash, to produce steam in a boiler, and the steam is used to power an electric generator turbine. MSW is a mixture of energy-rich materials such as paper, plastics, yard waste, and products made from wood. For every 100 pounds of MSW in the United States, about 85 pounds can be burned as fuel to generate electricity. The most common waste-to-energy system in the United States is the mass-burn system. In this system, unprocessed MSW is burned in a large incinerator with a boiler and a generator to produce electricity. A less common type of system processes MSW to remove noncombustible materials to produce refuse-derived fuel (RDF).

Although different disposal ways are available, incineration is a leading harmless approach to effectively recover energy among the applied technologies. The purpose of the present review paper is to detail the discussion of evolution of waste to energy incineration and specifically to highlight the currently used and advanced incineration technologies, including combined incineration with other energy, for instance, hydrogen production, coal and solar energy. In addition, the environmental performance is discussed, including the zero waste emission, leachate and fly ash treatment, climate change contribution and public behaviour. Finally, challenges, opportunities and business model are addressed. Trends and perspectives on policies and techno-economic aspects are also discussed in this review. Different simulation tools, which can be used for the thermodynamic assessment of incineration plants, are debated; life-cycle inventory emissions and most critical environmental impacts of such plants are evaluated by life-cycle analysis. This review shows that waste incineration with energy yield is advantageous to handle waste problems and it affects climate change positively.

Future Prediction of Waste-to-Energy Conversion Technology

WTE, also known as Energy from Waste (EfW), entails generating energy in the form of electricity and/or heat from the combustion of waste. WTE plants burn municipal solid waste (MSW), or trash, to produce steam in a boiler, and the steam is used to power a turbine generator. Mass burn WTE is the industry standard, where all waste is combusted as received without preprocessing.

WTE generates revenue from the sale of electricity to the utility. Local electric utilities are required to purchase all electricity generated by the WTE plant. These plants on average export 550 kwh/ton of processed MSW. The revenue from this electricity varies depending on the purchasing utility and when the facility was contracted.

Waste-to-Energy (WtE) technologies represent a fascinating intersection of waste management and renewable energy production, offering a dual solution to two of the world's most pressing issues. This blog post delves into the realm of WtE technologies, exploring their mechanisms, benefits, and the promising potential they hold for a sustainable future.

WTE technologies involve the conversion of non-recyclable waste materials into usable heat, electricity, or fuel through various processes. This not only helps in reducing the volume of waste sent to landfills but also in generating energy, thus serving a dual purpose. The most common WTE processes include incineration, gasification, pyrolysis, anaerobic digestion, and fermentation.

Waste-to-Energy technologies stand at the forefront of sustainable waste management and energy production. As we advance, the integration of innovative WtE solutions into our waste management infrastructure will be crucial for building resilient, energy-efficient, and sustainable societies. By embracing these technologies, we can turn our waste problem into an energy solution, moving closer to a future where every piece of waste is seen not as trash, but as a true energy resource.

Latest News

Ecoplanta Receives Approval: A Major Step Forward with Enerkem’s Groundbreaking Waste-to-Methanol Technology.

Montreal, January 29, 2025 – Enerkem, a global technology provider enabling low-carbon fuels and chemicals production from waste, is proud to announce that Repsol’s Board of Directors has officially approved the Final Investment Decision (FID) for the Ecoplanta project, marking a significant milestone in the drive for the supply of sustainable fuel and product.

Repsol’s Ecoplanta project will leverage Enerkem’s cutting-edge technology to transform non-recyclable municipal waste into sustainable methanol which can be used as a raw material to produce circular materials as well as advanced biofuels, contributing to the decarbonization of transport and chemicals.

Hitachi Zosen Inova Selected to Develop the World’s Most Advanced Waste to Energy Facility in Abu Dhabi

A consortium led by Marubeni Corporation, which includes Hitachi Zosen Inova and the Japan Overseas Infrastructure Investment Corporation for Transport & Urban Development, has been selected to design, build and operate a new ultra-large Waste to Energy facility on behalf of the Emirates Water & Electricity Company and Tadweer Group.

Abu Dhabi’s first WTE plant will be located near the Al-Dhafra landfill and will have a processing capacity of 900,000 tonnes of non-recyclable waste each year for the next 30 years. This will significantly boost Abu Dhabi’s transition away from reliance on landfill, considered by many as the least sustainable form of waste management. This important project will underpin the United Arab Emirates’ (UAE) goal to reduce carbon dioxide emissions by 1.1 million tonnes annually.

About Effectual Services

Effectual Services is an award-winning Intellectual Property (IP) management advisory & consulting firm offering IP intelligence to Fortune 500 companies, law firms, research institutes and universities, and venture capital firms/PE firms, globally. Through research & intelligence we help our clients in taking critical business decisions backed with credible data sources, which in turn helps them achieve their organisational goals, foster innovation and achieve milestones within timelines while optimising costs.

We are one of the largest IP & business intelligence providers, globally serving clients for over a decade now. Our multidisciplinary teams of subject matter experts have deep knowledge of best practices across industries, are adept with benchmarking quality standards and use a combination of human and machine intellect to deliver quality projects. Having a global footprint in over 5 countries helps us to bridge boundaries and work seamlessly across multiple time zones, thus living to the core of our philosophy - Innovation is global, so are we !!!

Solutions Driving Innovation & Intelligence

Enabling Fortune 500's, R&D Giants, Law firms, Universities, Research institutes & SME's Around The Globe Gather Intelligence That

Protects and Nurtures Innovation Through a Team of 250+ Techno Legal Professionals.