Electric Conductor Integration in Plastic Components Part 3

Recommendation – 1: In-Mold Structural Electronics (IMSE)

The solution to the problem is proposed by Duratech Industries

- Technology Provider: Duratech Industries And TactoTek

- Technology for integrating electric conductors in plastic components: In-Mold Structural Electronics® (IMSE) manufacturing technology

- Type of Molding (injection and/or compression): Injection molding

- Type of material used in molding:

- Polycarbonate

- Polyester

- Acrylics (PMMA)

- Conductive inks

- Advantages of Technology (Cost effectiveness/Large scale production): Cost-effective, durable components that are ready to flow into full-scale production

- Application Area: Automotive(In-Mold Decorated (IMD) applications with backlit options, designs can be used for dashboard components, buttons and indicators, center consoles, and PRNDLs)

- Licensing requirement: Yes (DuraTech is proud to partner with TactoTek, a deep tech company that develops and promotes IMSE with over 170 granted patents around the world)

- Technology Readiness Level: 9

- Safety/Regulatory Information: ISO certification and UL and CSA registrations

Introduction

Duratech create innovative human machine interface (HMI) solutions for many industries with In-Mold Structural Electronics® (IMSE) manufacturing technology. Known as the perfect union of form and function, IMSE fully integrates printed, conductive inks with In-Mold Decorating (IMD) to create a complete HMI solution in a single part. Sometimes referred to as in-mold electronics (IME), IMSE solutions simplify and accelerate product assembly. IMSE parts are lighter, more resistant to damage, simplify the bill of materials and ultimately reduce total cost of ownership. IMSE solutions represent proven processes and technology in a different form, creating significant benefits for manufacturers across industries.

Custom IMSE manufacturing capabilities

DuraTech can deliver fully customized IMSE solutions to meet nearly any need. Company IMSE manufacturing capabilities allow them to incorporate various types of LED lights, buttons and controls, finishes and a wide range of colors for a unique user experience. Our IMSE capabilities allow us to create cost-effective, durable components that are ready to flow into full-scale production.

Illumination

IMSE enables multiple styles of illumination for a superior user experience. Choose between single color or RGB in static and dynamic implementations from LEDs, all integrated within the 3D IMSE structure. Applications include localized icon backlighting, light lines showing control levels, and large area decorative ambient illumination.

Advanced IMSE technology and processes

DuraTech is proud to partner with TactoTek, a deep tech company that develops and promotes IMSE with over 170 granted patents around the world. Company partnership gives them access to TactoTek's advanced technology and processes, allowing Duratech to enhance company IMSE offerings and provide manufacturers with more electronic functionality. Together, company capabilities enable new integrations while optimizing cost and manufacturability of IMSE for many diverse applications.

IMSE applications and benefits

- Reduced cost of ownership

- Unique, flexible design

- Extremely reliable capacitive switch because there are no moving parts

- Encapsulated circuit, sensors and other components

- Efficient variant management

- Simplified bill of materials

- The elimination of wires allows for a thin, lightweight, durable control panel

- No cracks or crevices around buttons for dirt and bacteria to hide

- Eliminates the need for bulky tech boxes

- Produces less waste, making the manufacturing process more environmentally friendly

Why choose DuraTech Industries

- Manufacturers choose DuraTech for custom in-mold structural electronics solutions because company have the knowledge, experience and technical skill to create outstanding products with every production run.

- Duratech materials science expertise and global reach provide exceptional value and help accelerate the product development process.

TactoTek

The manufacturing process

IMSE manufacturing has four main process steps. IMSE combine cosmetics, structure, and function into single injection-molded 3D designs, reducing assembly and integration challenges compared with conventional electronics.

- Screen Printing: IMSE manufacturing starts with printing. Decoration, if desired, is printed on film insert molding (FIM) material, followed by printing electronics including conductive circuitry, touch controls, antennas and proximity sensors.

- Surface Mounting: Electronic components are mounted using standard high-speed pick-and-place (SMT) equipment. Components are attached to the FIM substrate using conductive and structural adhesives.

- Thermoforming: Thermoforming transforms the flat electronics film into its 3D shape. TactoTek® design rules and verified material stacks maintain mechanical and electrical system integrity through the forming process.

- Smart film insert molding: The formed electronics film is used as an insert for injection molding, resulting in a single-piece structure with encapsulated electronics. Typical molding materials include high pressure, high temperature plastics such as polycarbonate and thermoplastic polyurethane (PC and TPU).

Recommendation – 2: US20240112969A1 - In-mold electronics device

The solution to the problem is proposed by Industrial Technology Research Institute ITRI

US20240112969A1 Published in 2024

- Technology Provider: Industrial Technology Research Institute ITRI

- Technology for integrating electric conductors in plastic components: Injection molding technology

- Type of Molding(injection and/or compression): Injection molding

- Type of material used in molding:

- Polyethylene terephthalate, poly (ethylene terephthalateco-1,4-cylclohexylenedimethylene terephthalate), polycarbonate, polyimide, polymethylmethacrylate, polyethersulfone, polydimethylsiloxane, acrylonitrile-butadiene-styrene copolymer, acrylic

- Gold, silver, copper, aluminum, nickel, tin

- Acrylic, epoxy resin, phenol, polyester, urethane, silicone, or polyimide

- Advantages of Technology (Cost effectiveness/Large scale production):

- Reduce product development time

- Improving reliability

- Application Area: Automobile industry

- Licensing requirement: ITRI uses innovative IME design guidelines and development platform for creative versatile types of circuit, contact and interface design to reduce product development time.

- Safety/Regulatory Information: Effectively solving the problem of the release of organic gas and dust (formaldehyde PM 2.5) into the environment and maintaining treatment efficiency at over 70%

Introduction

- ITRI is a world-leading applied technology research institute with more than 6,000 outstanding employees.

- Its mission is to drive industrial development, create economic value, and enhance social well-being through technology R&D.

- Founded in 1973, it pioneered in IC development and started to nurture new tech ventures and deliver its R&D results to industries.

- ITRI has set up and incubated companies such as TSMC, UMC, Taiwan Mask Corp., Epistar Corp., Mirle Automation Corp., and Taiwan Biomaterial Co.

Services

- ITRI is ceaselessly developing advanced technologies and strengthening interdisciplinary integration to respond the latest industry trends.

- Moreover, it offers comprehensive R&D collaboration and business consulting services, such as contract research, small-scale pilot production, process improvement, calibration and measuring, technology transfers, and IP value-added services.

- With its open labs and incubators to promote startups and entrepreneurship, ITRI is active to speed up technological development in industries and nurture emerging high-tech businesses.

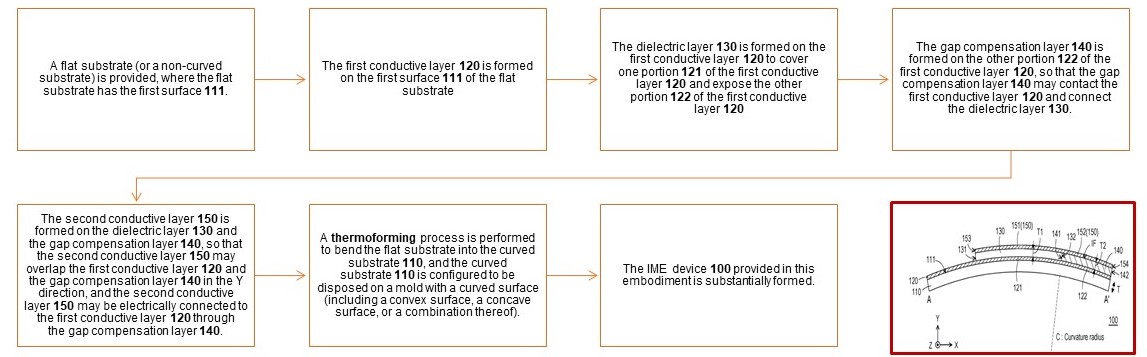

Method of manufacturing the IME device

The IME device provided in one or more embodiments of the disclosure is able to mitigate the issue of the abnormal interface structure (e.g., peeling or wrinkles) caused by the heating and molding process, thereby enhancing the reliability for the IME device provided in one or more embodiments of the disclosure.

In addition, according to some embodiments, the issue of the abnormal interface structure (e.g., peeling or wrinkles) caused by the thermoforming process at the structural gap may be mitigated by arranging the gap compensation layer between the second portion of the second conductive layer and the other portion of the first conductive layer, ensuring the second portion of the second conductive layer to overlap the gap compensation layer in the Y direction, and aligning the second side surface of the second conductive layer with the side surface of the gap compensation layer away from the dielectric layer, thereby improving the reliability of the IME device having the gap compensation layer.

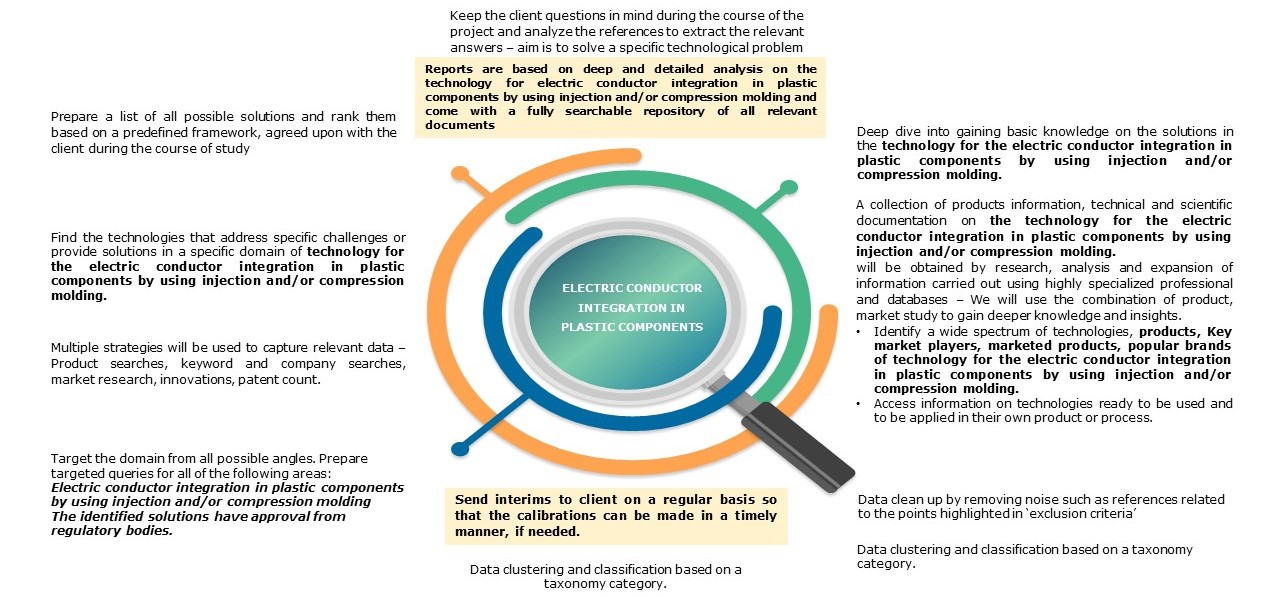

Proposed Strategy

Key points of Proposed Strategy

Scope

- Patent + Non-patent scientific literature

- Product Portfolio Analysis/ Product Development Process

- Market Research – Product Portfolio Analysis, Market Player Analysis, etc.

- Regulatory Requirement

- Worldwide coverage- Preference on United States, Europe and China

- No restriction on timeline.

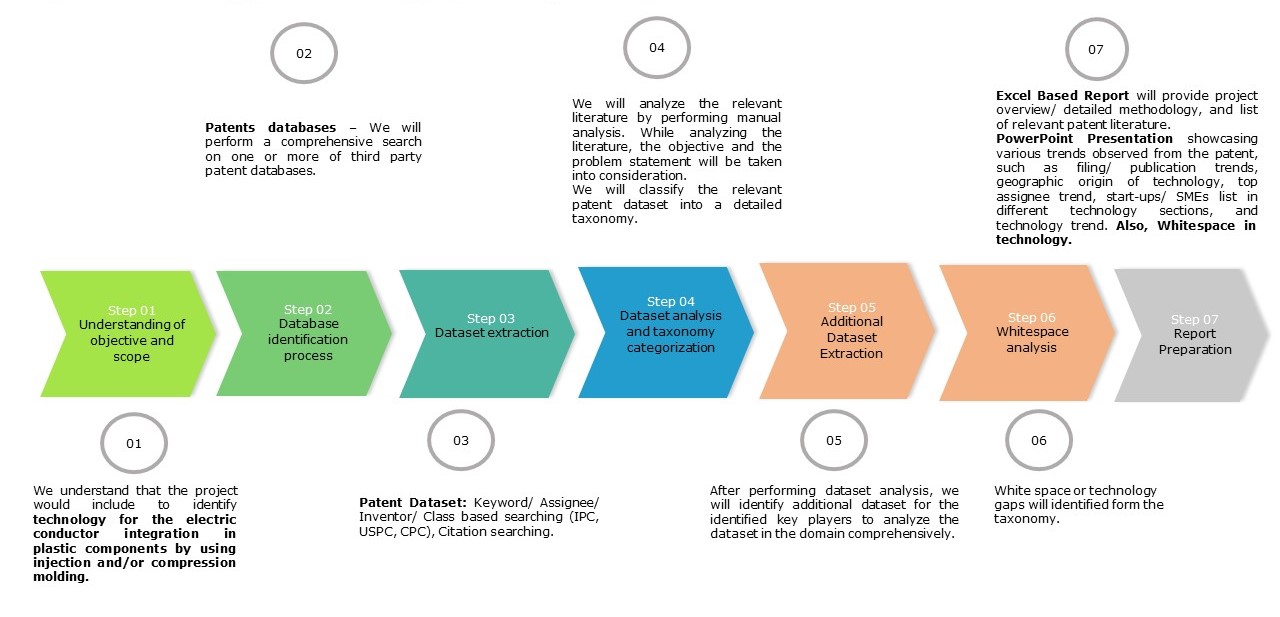

Patent databases

The following data sources will be followed to collate the information:

- Derwent Innovation

- Questel Orbit

- PatSeer

- USPTO

- Espacenet

- PatentScope

- Google Patent

- OrangeBook

Note that highlighted in bold font databases cover 100+ jurisdictions.

Patents will be analyzed on the basis of title, abstract, claims, and will be tagged as per the taxonomy. The non-English data will be analyzed based on the machine translated text provided by third party databases. The patents will be analyzed based on one member per INPADOC family.

Non Patent Scientific Literature databases

The following data sources will be followed to collate the information:

- IEEE

- Wiley Online

- Google Scholar

- Academic thesis

- Forums/ Blogs

- Books/ chapters

Non-patent scientific literature will be analyzed on the basis of title and abstract in English language, and taxonomy will be tagged accordingly.

Safety Requirement

The following agencies will be followed to collate the information:

- RoHS

- REACH

- Others

Regulatory guidelines will be analyzed to check safety of technology.

Market Research Databases

The following data sources will be followed to collate the information:

- News articles

- Market reports (if publicly available)

- Magazines/Journals

- Companies’ websites

- Product brochures

- Marketing material from competitors

- Industry associations

- Conferences

- Articles

- General Google

Market research will be a desktop exercise and based on information available publically via open web sources.

How we plan to make it comprehensive and focused

Proposed Methodology for IP landscape + White space analysis

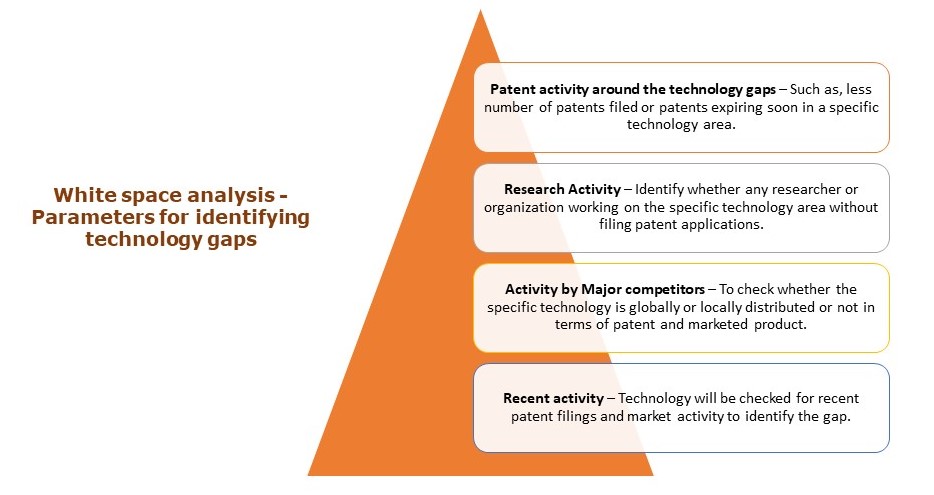

Parameters – White space Analysis

White space or technology gaps were identified for each topic. In white space analysis, we identify technology gaps that can be used for further patenting activity or future research or product development.

# Please note that above analysis has been done based on one representative member per patent family.

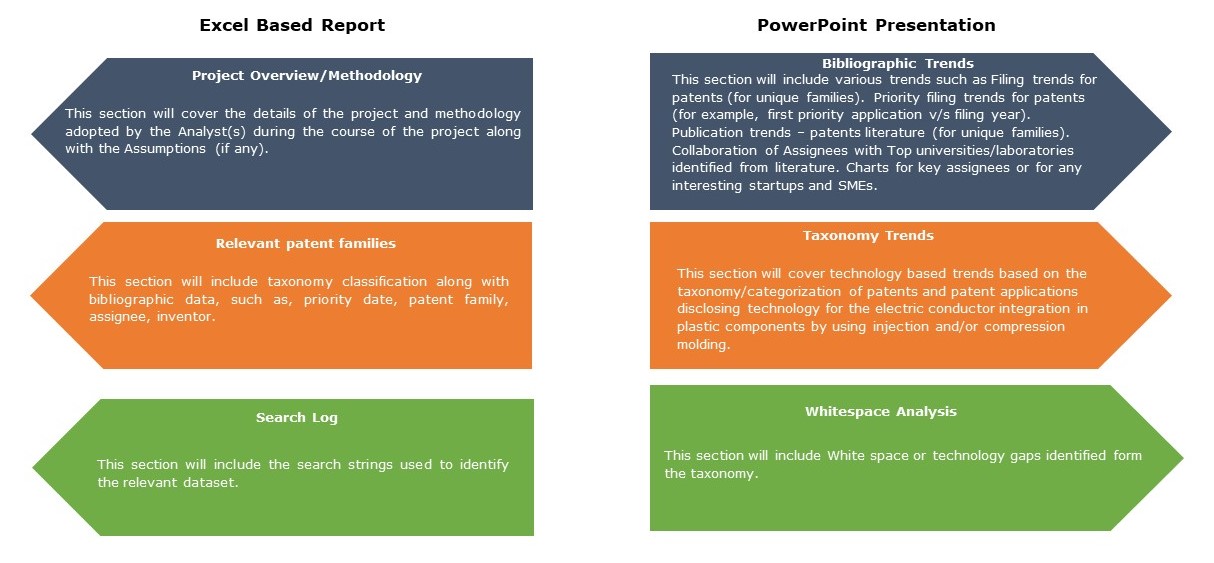

Report Preparation-Phase-I

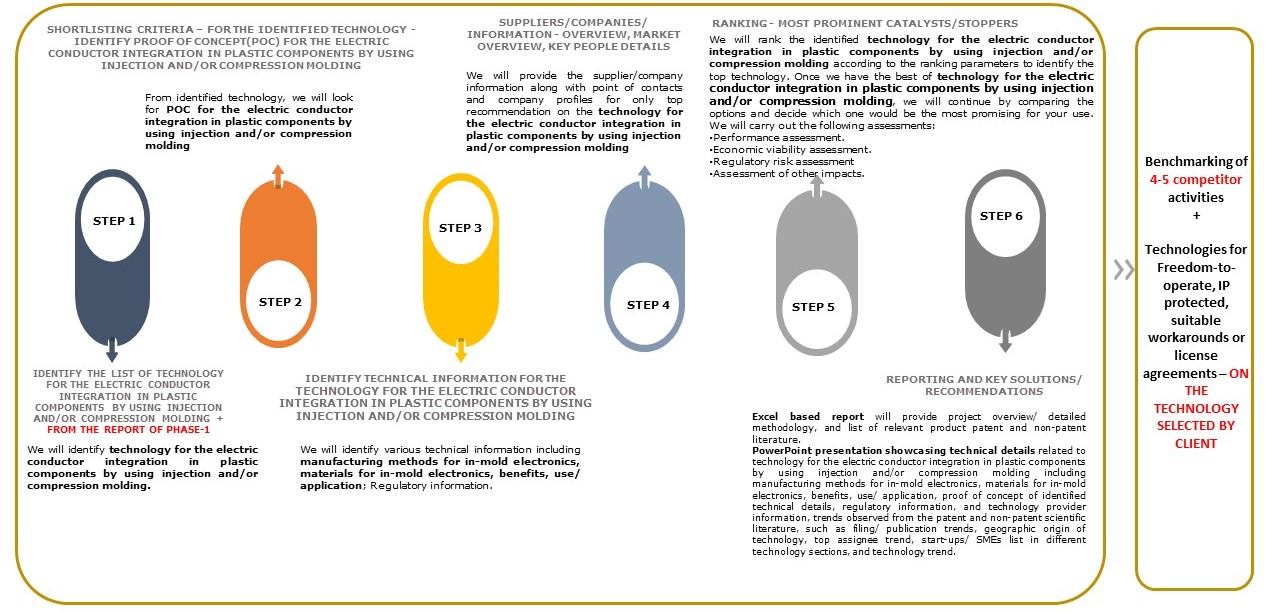

Proposed Methodology – Cost Effective Technology + Benchmarking of 4-5 competitors + FTO on selected technology by Client -Broad

About Effectual Services

Effectual Services is an award-winning Intellectual Property (IP) management advisory & consulting firm offering IP intelligence to Fortune 500 companies, law firms, research institutes and universities, and venture capital firms/PE firms, globally. Through research & intelligence we help our clients in taking critical business decisions backed with credible data sources, which in turn helps them achieve their organisational goals, foster innovation and achieve milestones within timelines while optimising costs.

We are one of the largest IP & business intelligence providers, globally serving clients for over a decade now. Our multidisciplinary teams of subject matter experts have deep knowledge of best practices across industries, are adept with benchmarking quality standards and use a combination of human and machine intellect to deliver quality projects. Having a global footprint in over 5 countries helps us to bridge boundaries and work seamlessly across multiple time zones, thus living to the core of our philosophy - Innovation is global, so are we !!!

Related Resources:

Solutions Driving Innovation & Intelligence

Enabling Fortune 500's, R&D Giants, Law firms, Universities, Research institutes & SME's Around The Globe Gather Intelligence That

Protects and Nurtures Innovation Through a Team of 250+ Techno Legal Professionals.