Electric Conductor Integration In Plastic Components Part 2

The automotive industry has been one of the major adopters of in mold electronics technology. In mold electronics allows integrating electronic components such as sensors, antennae and illuminated logos directly into plastic vehicle parts during the injection molding process. This method has advantages compared to traditional methods. It removes the need for extra assembly steps after molding, simplifying the manufacturing process. It also allows for better integration of electronics with vehicle structures, enabling new and creative uses.

Regulations mandating safety features like backup cameras are also driving automotive manufacturers to explore in mold electronics. Integrating camera modules directly into tailgates or license plate housing addresses reliability issues associated with detachable camera units. As autonomous, connected and electric vehicles gain wider acceptance, the level of electronics and amount of sensors in vehicles is expected to multiply tremendously. This puts the spotlight on in mold electronics that enables simplified assembly of vehicles with high electronic content. The growing electrification of automobiles is another driver, as in mold technology supports novel approaches to integrating electronic controls and displays. With its ability to enable innovation and help comply with regulations, in mold electronics is sure to play a pivotal role in automotive industry's transformation in coming years.

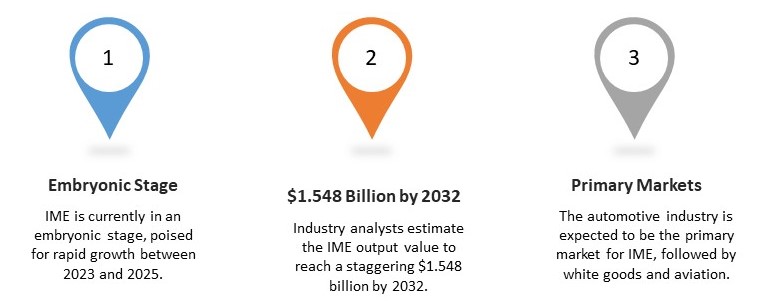

The Rise of IME

Key Players

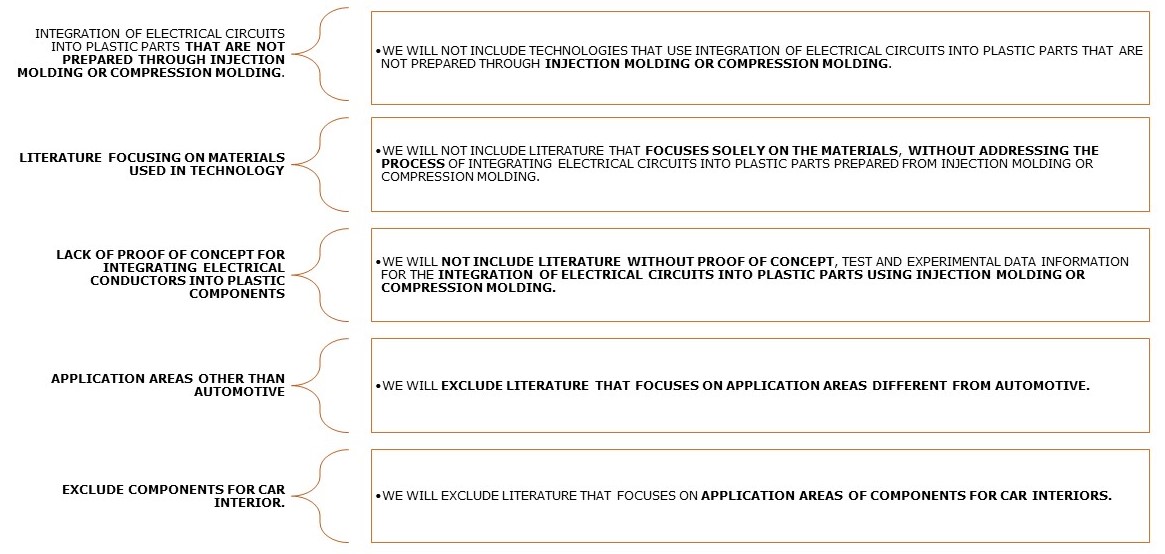

Scope – Non-Interesting Technologies

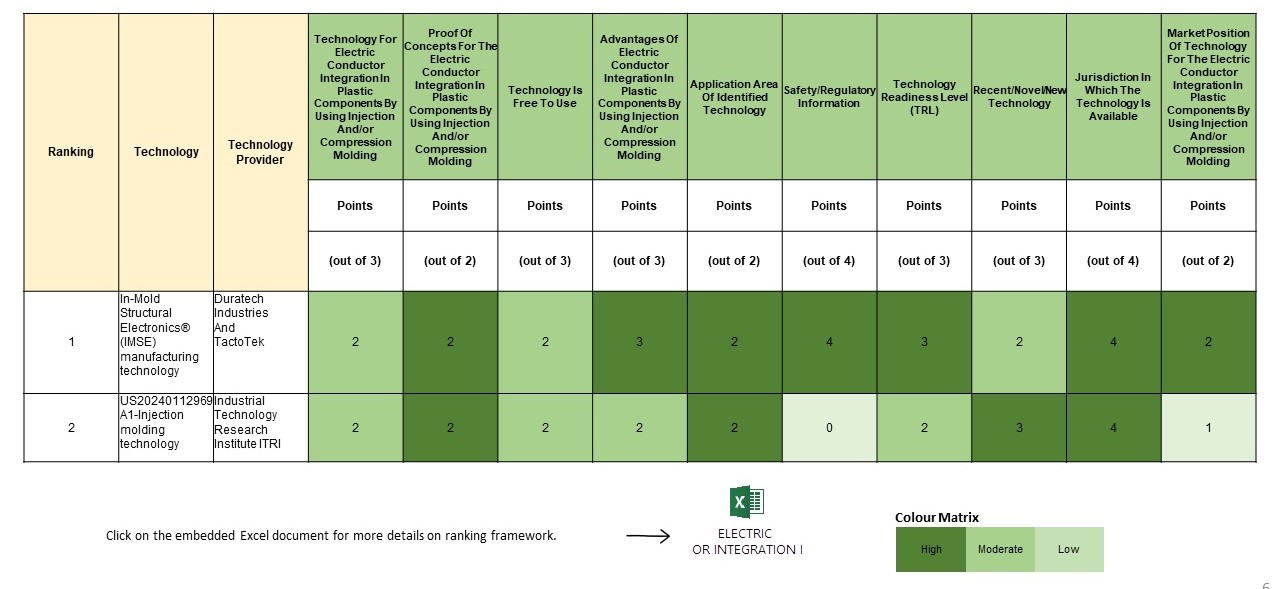

Ranking Framework

Technology for Electric Conductor Integration in Injection-molded or Compression-Molded Plastic Parts

- 3 points if the identified technology specifically addresses the integration of electrical circuits in both injection-molded or compression-molded plastic parts.

- 2 points if the identified technology specifically addresses the integration of electrical circuits in either injection-molded or compression-molded plastic parts.

- 0 points if the identified technology specifically addresses the integration of electrical circuits in neither injection-molded nor compression-molded plastic parts

Proof of Concepts for the Electric Conductor Integration in Plastic Components by Using Injection and/or Compression Molding

- 2 points if the identified technology discusses proof of concept or test data for the electric conductor integration in plastic components by using injection and/or compression molding.

- 1 point if the identified technology does not discuss proof of concept or test data.

Technology is Free to Use

- 3 points if the identified technology is free to use.

- 2 points if the identified technology is easily licensable.

- 1 point if the identified technology is not licensable and is used by only one particular competitor.

Advantages of Electric Conductor Integration in Plastic Components by Using Injection and/or Compression Molding

- 3 points if the identified technology is cost-effective and can be easily produced on a large scale in industries.

- 2 points if the identified technology is either cost-effective or easy to produce at an industrial scale.

- 0 point if the identified technology is neither cost-effective nor easy to produce at an industrial scale.

Application Area of Identified Technology

- 2 points if the identified technology specifically used for automotive exteriors.

- 1 point if there is no information available for the application area of technology.

Safety/Regulatory Information

- 4 points if the material, chemical, or process used in the technology for the electric conductor integration in plastic components by using injection and/or compression molding is safe for use, and if it is approved by RoSH or REACH, with information obtained from the relevant regulatory body or organization website

- 3 points if the material, chemical, or process used in the technology for the electric conductor integration in plastic components by using injection and/or compression molding is safe for use, and if it is approved by US or European or Chinese regulatory authorities and Information were fetched from third party website.

- 2 points the material, chemical, or process used in the technology for the electric conductor integration in plastic components by using injection and/or compression molding is safe for use and approved by other than the US/Europe regulatory authorities and Information were fetched from concerned regulatory body/organization website.

- 1 point if the material, chemical, or process used in the technology for the electric conductor integration in plastic components by using injection and/or compression molding is safe for use and approved by other than the US/Europe regulatory authorities and Information were fetched from third party website.

- 0 point if there is no information available for regulatory information.

Technology Readiness Level (TRL)

- 3 Points if the innovation in technology for the electric conductor integration in plastic components by using injection and/or compression molding exhibits a TRL level falling within the range of 7-9. (Deployment/commercialization).

- 2 Points if the innovation in technology for the electric conductor integration in plastic components by using injection and/or compression molding exhibits a TRL level falling within the range of 4-6 (Technology Development & Demonstration).

- 1 Point if the innovation in the technology for the electric conductor integration in plastic components by using injection and/or compression molding exhibits a TRL level of 1-3 (Research Stage).

Recent/Novel/New Technology

- 3 points if the technology for integrating electric conductors into plastic components using injection and/or compression molding has been developed in the last 3 years and is specifically described as a novel or new technology.

- 2 points if the technology for integrating electric conductors into plastic components using injection and/or compression molding was developed between 4 and 10 years ago.

- 1 point if the technology for integrating electric conductors into plastic components using injection and/or compression molding was developed between 11 and 15 years ago.

- 0 point if the technology for integrating electric conductors into plastic components using injection and/or compression molding was developed more than 15 years ago.

Jurisdiction in Which the Technology is Available

- 4 points if the technology for integrating electric conductors into plastic components using injection and/or compression molding is available in all three jurisdictions: the United States, Europe, and China..

- 3 points if the technology for integrating electric conductors into plastic components using injection and/or compression molding is available in any two of the following jurisdictions: the United States, Europe, or China.

- 2 points if the technology for integrating electric conductors into plastic components using injection and/or compression molding is available in only one jurisdiction: the United States, Europe, or China..

- 1 point if the technology for integrating electric conductors into plastic components using injection and/or compression molding is available in a jurisdiction other than the United States, Europe, or China.

Market Position of Technology for The Electric Conductor Integration in Plastic Components by Using Injection and/or Compression Molding

- 2 points if the technology for the electric conductor integration in plastic components by using injection and/or compression molding is currently available in a marketed product or service.

- 1 point if the technology for the electric conductor integration in plastic components by using injection and/or compression moldings not available in a marketed product or service

Ranking Matrix

Proposed Methodology for IP landscape + White space analysis

Phase-I

Step 01 - Understanding of objective and scope: We understand that the project would include to identify technology for the electric conductor integration in plastic components by using injection and/or compression molding.

Step 02 - Database identification process: Patents databases – We will perform a comprehensive search on one or more of third party patent databases.

Step 03 - Dataset extraction: Patent Dataset: Keyword/ Assignee/ Inventor/ Class based searching (IPC, USPC, CPC), Citation searching.

Step 04 - Dataset analysis and taxonomy categorization: We will analyze the relevant literature by performing manual analysis. While analyzing the literature, the objective and the problem statement will be taken into consideration. We will classify the relevant patent dataset into a detailed taxonomy.

Step 05 - Additional Dataset Extraction: After performing dataset analysis, we will identify additional dataset for the identified key players to analyze the dataset in the domain comprehensively.

Step 06 - Whitespace analysis: White space or technology gaps will identified form the taxonomy.

Step 07 Report Preparation: Excel Based Report will provide project overview/ detailed methodology, and list of relevant patent literature. PowerPoint Presentation showcasing various trends observed from the patent, such as filing/ publication trends, geographic origin of technology, top assignee trend, start-ups/ SMEs list in different technology sections, and technology trend. Also, Whitespace in technology.

Parameters– White space Analysis

White space analysis - Parameters for identifying technology gaps

White space or technology gaps were identified for each topic. In white space analysis, we identify technology gaps that can be used for further patenting activity or future research or product development.

- Patent activity around the technology gaps – Such as, less number of patents filed or patents expiring soon in a specific technology area.

- Research Activity – Identify whether any researcher or organization working on the specific technology area without filing patent applications.

- Activity by Major competitors – To check whether the specific technology is globally or locally distributed or not in terms of patent and marketed product.

- Recent activity – Technology will be checked for recent patent filings and market activity to identify the gap.

* Please note that above analysis has been done based on one representative member per patent family.

Phase-II

Proposed Strategy – Detailed Methodology- Phase-II

Step 01 - Understanding of objective and scope

We understand that the project would include to identify technology for the electric conductor integration in plastic components by using injection and/or compression molding.

Step 02 - Database identification process

Patents databases – We will perform a comprehensive search on one or more of third party patent databases

Non-patent databases (Scientific literature + Product research) – We will perform a comprehensive search on one or more of non-patent databases.

Step 03 - Dataset extraction

Patent Dataset: Keyword/ Assignee/ Inventor/ Class based searching (IPC, USPC, CPC), Citation searching.

Non-patent Dataset: Keyword/ Company/ academic/ patent inventor based searching, Citation based searching.

Step 04 - Dataset analysis

We will analyze the relevant literature by performing manual analysis. While analyzing the literature, the objective and the problem statement will be taken into consideration.

We will classify the relevant patent and non-patent dataset into a detailed taxonomy.

Step 05 - Identifying technical details

After performing dataset analysis, we will prepare a list of technologies that will be further scrutinize for detailed technical details such as Proof of concept, manufacturing methods for in-mold electronics, materials for in-mold electronics, benefits, use/ application; Regulatory information

What are the top technology for the electric conductor integration in plastic components by using injection and/or compression molding.

Step 06 - Regulatory information

We will check regulatory approval information, guideline details of technology for the electric conductor integration in plastic components by using injection and/or compression molding. We will also look for safety information/guideline.

Step 07 - Market Analysis+Suppliers

We will check the market activity of identified technology for the electric conductor integration in plastic components by using injection and/or compression molding. to know the details of players who are working or using such technology in the domain of intrest.

Step 08 - Ranking of technology

We will rank the identified technology for the electric conductor integration in plastic components by using injection and/or compression molding to the ranking parameters such as proof of concept, advantages, regulatory approvals etc.

Step 09 - Report Preparation

Excel based report will provide project overview/ detailed methodology, and list of relevant product/services, patent and non-patent literature.

Step 10 - Key Solutions/Recommendations

PowerPoint presentation showcasing technical details related to the technology for the electric conductor integration in plastic components by using injection and/or compression molding including manufacturing methods for in-mold electronics, materials for in-mold electronics, benefits, use/ application, proof of concept of identified technical details, regulatory information, and technology provider information, trends observed from the patent and non-patent scientific literature, such as filing/ publication trends, geographic origin of technology, top assignee trend, start-ups/ SMEs list in different technology sections, and technology trend.

About Effectual Services

Effectual Services is an award-winning Intellectual Property (IP) management advisory & consulting firm offering IP intelligence to Fortune 500 companies, law firms, research institutes and universities, and venture capital firms/PE firms, globally. Through research & intelligence we help our clients in taking critical business decisions backed with credible data sources, which in turn helps them achieve their organisational goals, foster innovation and achieve milestones within timelines while optimising costs.

We are one of the largest IP & business intelligence providers, globally serving clients for over a decade now. Our multidisciplinary teams of subject matter experts have deep knowledge of best practices across industries, are adept with benchmarking quality standards and use a combination of human and machine intellect to deliver quality projects. Having a global footprint in over 5 countries helps us to bridge boundaries and work seamlessly across multiple time zones, thus living to the core of our philosophy - Innovation is global, so are we !!!

Solutions Driving Innovation & Intelligence

Enabling Fortune 500's, R&D Giants, Law firms, Universities, Research institutes & SME's Around The Globe Gather Intelligence That

Protects and Nurtures Innovation Through a Team of 250+ Techno Legal Professionals.