Water Dispersible: Challenges and Key Assignees

Current challenges in soluble bio-based unit dosage format

Laundry detergent pods (or packs or liquitabs) are water-soluble pouches containing highly concentrated laundry detergent, softener and other laundry products. Notable brands of these packs include All, Arm & Hammer, Gain, Purex, Persil and Tide. They first became popular in February 2012 when they were introduced by Procter & Gamble as Tide Pods. The chemistry of laundry detergent packs is the same as in liquid detergents (including alkylbenzenesulfonates). The dissolvable packets are typically made of polyvinylalcohol (PVA) or a derivative of PVA. Although the formulas are similar, a detergent pack's liquids may contain 10% water compared to 50% in liquid detergents.

MonoSol is one of the companies that develops the water-soluble film used for laundry and dishwasher detergent packs, used by brands including Tide, with roughly $250 million in annual sales and controlling around 90-percent of the market. The film is designed to be soluble in cold water. While PVA is water-soluble and technically biodegradable under specific conditions, it's estimated that close to 15,000 metric tons of intact PVA either bypass or make it through treatment facilities every year.

Laundry pods are estimated to make up about 15% of the $7 billion-a-year U.S. laundry detergent market sales according to market researcher Nielsen NV. Laundry pods were advertised as a way to reduce wasted use of powdered and liquid detergent by having precise measurements for a load. For large loads, most brands recommend two pods, with Tide suggesting up to three. Detergent pods cost significantly more than liquid detergent for equivalent laundry loads.

The major challenges faced by soluble bio-based unit dosage format are:

- Pods can contribute to plastic pollution when they’re used the “right” way. They leak large amounts of untreated PVA that can potentially enter groundwater resources and water systems and contaminate the human food chain.

- While PVA can be fully biodegradable, specific conditions are needed for that to happen. Wastewater treatments plants in the United States are generally built to treat human waste and other biological matter, and don’t create optimal conditions for PVA to biodegrade, the researchers say.

- The moment these pods are subjected to water, they solubilize into a plastic solution. This plastic solution can easily pass through conventional water treatment and into ecosystems beyond. For those main reasons, pollution from these detergent pods is cause for concern.

- The study estimate nationwide emissions of PVA from the domestic use of laundry and dish detergent pods. Researchers concluded that as much as 75% of PVA from detergent pods goes untreated in the United States, with more than 8,000 tons per year entering the environment.

- Plastic residue has demonstrated negative effects on the environment and to the food chain by acting as vectors of harmful contaminants.

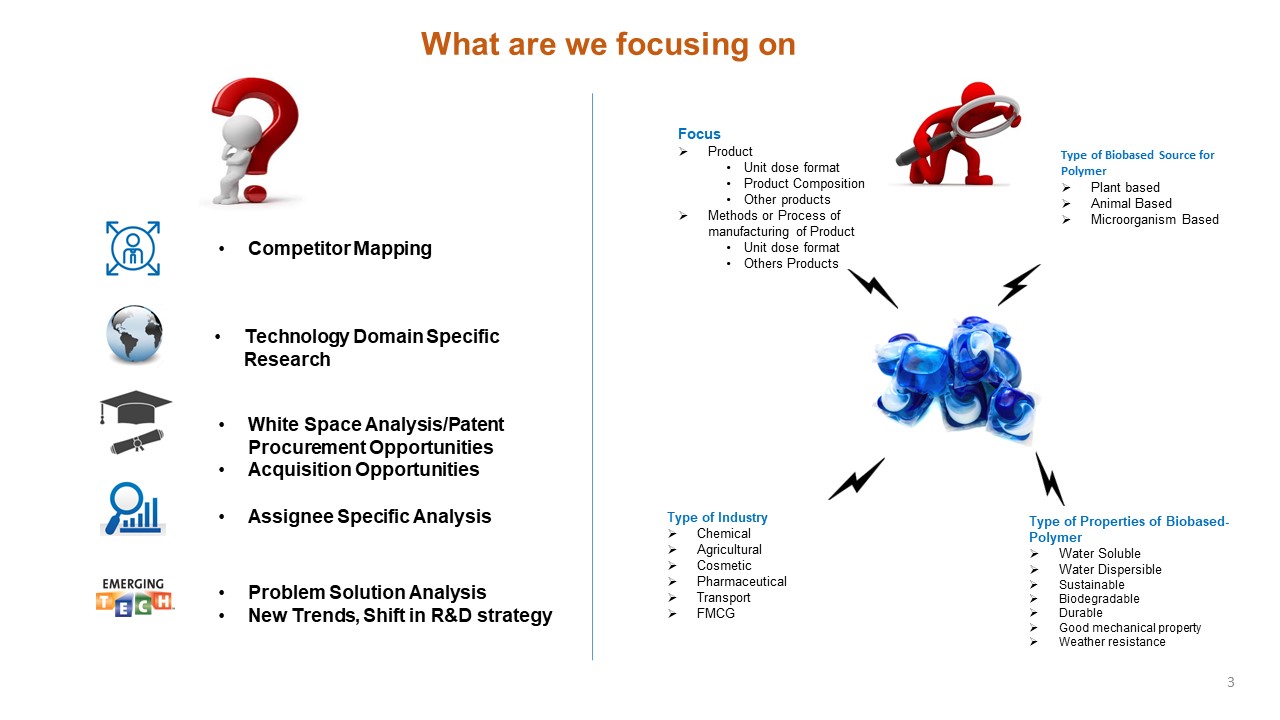

What are we focusing on

Water Dispersible: Key Assignees

Companies

Academics

SMEs or Startups

Competitor Mapping (key leaders, innovators, R&D strategy)

Top Competitors- Procter & Gamble

The Procter & Gamble Company (P&G) is an American multinational consumer goods corporation headquartered in Cincinnati, Ohio, founded in 1837 by William Procter and James Gamble. It specializes in a wide range of personal health/consumer health, and personal care and hygiene products;

The products of Procter & Gamble are organized into several segments including Beauty; Grooming; Health Care; Fabric & Home Care; and Baby, Feminine, & Family Care. P&G is incorporated in Ohio.

P&G have 82 patents in water soluble biobased unit dose format.

- P&G, the maker of everything from Pampers diapers to Pantene shampoo, has built its 175-year history on creating things people need and then improving them. (Think: Ivory soap in 1879; Swiffer Sweeper in 1999.) Each year, the company spends $2 billion on research and development and rolls out about 27 products worldwide - more than two a month. That focus on innovation has paid off. P&G says 98 percent of American households have at least one of its products in their cupboards, broom closets or bathrooms and while about 15 to 20 percent of all new products succeed, P&G has claimed a 50 percent success rate. Four of the top 10 new consumer products in 2010 were made by P&G, according to research firm SymphonyIRI.

- Procter & Gamble released its first laundry tablet in the 1960s, but the product flopped in the US due to performance drawbacks. It took an even older technology -- a water soluble polymer called PVOH -- to launch unit dose detergent into the mainstream.

- Pod-like products had been on the market before. P&G introduced tablets filled with powder detergent in 2000, but yanked them from stores shelves two years later. The problem was that powder tablets didn't always dissolve completely, leading to messiness. They also worked only in hot water. To make sure Tide Pods would dissolve in cold water too, P&G turned to MonoSol, a company that makes water soluble films. MonoSol developed a polyvinyl alcohol film that not only dissolves in any temperature water, but even in sweaty palms. The film also is strong - it won't break even when stretched over the top of a can of marbles and shaken - but soft to the touch.

- MonoSol, a Kuraray Company, the world leader in manufacturing water soluble films, announces that it has been recognized by Procter & Gamble as its 2012 Connect+Develop Partner of the Year for accelerating innovation breakthroughs that drive business results. As the only supplier to receive this top honor, it reflects intense collaboration between the two companies. P&G partnered with MonoSol to develop Tide Pods, which was launched this year and has already achieved a 68 percent share of the U.S. unit dose laundry segment thanks to its unique look and feel, excellent performance and superior customer convenience. Tide Pods is a single-use packet with three chambers that hold liquid detergent, a stain fighter and a brightener. For the project, MonoSol developed a new proprietary film that dissolves rapidly in the wash, even in cold water, yet holds up to wet hands.

- Procter & Gamble Chief Sustainability Officer, Virgeny Helios, said that P&G’s European fabric care business is also committed to making all brands of packaging fully recyclable by 2022. This move will be critical to P&G's commitment to reduce fresh plastic packaging by 50% by 2030. Procter & Gamble said that by 2025, the plastic used by the Procter & Gamble brand will be reduced by 15,000 tons per year compared with 2018.

- Procter & Gamble, a global manufacturer of consumer goods and household products has witnessed sales to the tune of US$ 1.5 billion from their product named “Tide Pods and Ariel Pods” that are laundry detergent pods.

Top Competitors- Rhône-Poulenc

Rhône-Poulenc (French pronunciation: [ʁon pulɛ̃k]) was a French chemical and pharmaceutical company founded in 1928. In 1999 it merged with Hoechst AG to form Aventis. As of 2015, the pharmaceutical operations of Rhône-Poulenc are part of Sanofi and the chemicals divisions are part of Solvay group and Bayer Crop Science.

The company was founded in 1928 through the merger of Société des usines chimiques du Rhône (Society of Rhône Chemical Factories) from Lyon and Poulenc Frères (Poulenc Brothers) from Paris founded by Étienne Poulenc, a 19th-century Parisian apothecary and brought to prominence by his second and third sons Émile, father of composer Francis Poulenc, and Camille Poulenc (1864–1942).

In 1950, the company synthesized chlorpromazine which it sold to Smith, Kline & French (today part of GlaxoSmithKline) who marketed the drug as Thorazine.

In 1990, it merged with the pharmaceutical company Rorer to form Rhône-Poulenc Rorer.

In January 1999, Rhône-Poulenc merged with Hoechst AG to form Aventis.

In 2004, Aventis went on to merge with Sanofi-Synthélabo forming Sanofi-Aventis, the third largest pharmaceutical company in the world.

In 2011, Sanofi-Aventis decided to drop the Aventis suffix and change its name to Sanofi.

Rhône-Poulenc have 23 patents in water soluble biobased unit dose format.

- Sanofi is a global leader in healthcare and pharmaceuticals based in Paris, France. In 2020, Sanofi generated about 36 billion euros in revenues, the highest in recent years. In general, the company’s revenues have been increasing since 2006 when their revenues were 28.4 billion euros.

- Sanofi works in several therapeutic sectors including diabetes and cardiovascular diseases, oncology, immunology, multiple sclerosis, rare diseases, rare blood disorders, and vaccines. A majority of Sanofi’s revenues can be attributed to their pharmaceutical sector. Sanofi’s top pharmaceutical products, based on revenues include Dupixent, Lantus, and Aubagio. Lantus is a long-acting insulin for use in type I and type II diabetes. Sanofi also used to have an animal health sector but the business was sold to Boehringer Ingelheim in 2016.

- Sanofi has entered into a definitive merger agreement with Kadmon Holdings, Inc. (NASDAQ: KDMN) a biopharmaceutical company that discovers, develops, and markets transformative therapies for disease areas of significant unmet medical needs. The acquisition supports Sanofi’s strategy to continue to grow its General Medicines core assets and will immediately add Rezurock™(belumosudil) to its transplant portfolio. Rezurock is a recently FDA-approved, first-in-class treatment for chronic graft-versus-host disease (cGVHD) for adult and pediatric patients 12 years and older who have failed at least two prior lines of systemic therapy.

- As part of Sanofi’s endeavor to accelerate the application of messenger RNA (mRNA) to develop therapeutics and vaccines, the company has entered into a definitive agreement with Translate Bio (NASDAQ: TBIO), a clinical-stage mRNA therapeutics company, under which Sanofi will acquire all outstanding shares of Translate Bio for $38.00 per share in cash, which represents a total equity value of approximately $3.2 billion (on a fully diluted basis). The Sanofi and Translate Bio Boards of Directors unanimously approved the transaction.

- Sanofi has entered into an agreement to acquire Origimm Biotechnology, an Austria-based privately owned biotechnology company specializing in skin disease, which will boost Sanofi’s pipeline of vaccine candidates. The acquisition is expected to close in early December 2021.

- August 20, 2020 - Sanofi recently announced that it will acquire biopharmaceutical company, Principia Biopharma Inc, in a pharma acquisition deal of $100 per share in cash. Principia Biopharma focuses on developing treatments for immune-mediated diseases. Under the agreement, Sanofi will acquire all shares of the company, which represents an aggregate equity value of nearly $3.68 billion.

- According to Rhone-Poulenc's estimates, specialty polymers should see the strongest growth at 9 percent. Among these products are water-soluble polymers, such as packaging for pesticide gels that would dissolve in water before being applied to crops.

Other Competitors

In 2012 Kuraray Co., Ltd. (Kuraray) and MonoSol, LLC announced that Kuraray has agreed to acquire MonoSol, LLC (MonoSol), a market-leading manufacturer of water-soluble polyvinyl alcohol (PVA) films. This acquisition by Kuraray supports its strategy to expand its Vinyl Acetate Chemical Chain Business. Terms of the transaction were not disclosed.

Through this acquisition of MonoSol, Kuraray will expand its product offering of PVA films into a wider range of industrial applications, thereby enhancing its competitiveness. Kuraray currently supplies "POVAL" PVA film for optical-uses including a polarizing film, which is an essential component of liquid crystal displays.

MonoSol, LLC has been a leader in specialty water-soluble polymer-based films. MonoSol offers a wide range of water-soluble delivery systems for unit-dose applications for consumer, agricultural chemicals and industrial products, release films, transfer printing, embroidery support films, water-soluble laundry bags, edible films and TerraLOC, a unique dust abatement system. MonoSol maintains a global network of dedicated partners to offer sales, service and technical support to its worldwide customer base.

MonoSol, a Kuraray Company, the world leader in manufacturing water soluble films, announces that it has been recognized by Procter & Gamble as its 2012 Connect+Develop Partner of the Year for accelerating innovation breakthroughs that drive business results. As the only supplier to receive this top honor, it reflects intense collaboration between the two companies. P&G partnered with MonoSol to develop Tide Pods. Source 1 Source 2

Kuraray have 19 patents in water soluble biobased unit dose format, amongst them 17 patents are under name of Monosol.

Henkel AG & Co. KGaA is a German chemical and consumer goods company headquartered in Düsseldorf, Germany. It is a multinational company active both in the consumer and industrial sector. Source

Founded in 1876, the DAX company is organized into three globally operating business units (Laundry & Home Care, Beauty Care, Adhesive Technologies) and is known for brands such as Loctite, Persil and Purex, amongst others. Source

Henkel worked with raw material supplier Monosol for shell consists of soluble polyvinyl alcohol foil. Source

Henkel began selling its Megaperls powder dishwashing pods in the resulting flexible package, called a Quadro Seal Bag, that consists of an OPP/PE laminate. At present, 30% of the package’s PE layer consists of industrial waste reclaimed from Mondi’s factory in Halle, Germany. That means the overall package structure contains approximately 10% reground material. Source

Henkel have 18 patents in water soluble biobased unit dose format.

Unilever PLC is a British multinational consumer goods company headquartered in London, England. Unilever products include food, condiments, ice cream, wellbeing vitamins, minerals and supplements, tea, coffee, breakfast cereal, cleaning agents, water and air purifiers, pet food, toothpaste, beauty products, and personal care. Unilever is the largest producer of soap in the world.[3] Unilever's products are available in around 190 countries.

Unilever, owner of brands including Dove, Ben & Jerry’s, Lipton and Omo has announced ambitious new commitments to reduce its plastic waste and help create a circular economy for plastics.

In a bid to make the chore of doing laundry more efficient, Surf Excel by Hindustan Unilever has launched the Surf Excel 3 in 1 Smart Shots, a single-use soluble liquid detergent capsule with a unique three-chamber design, specially designed for fully automatic front and top load washing machines. The product contains smart technology for advanced stain removal, long-lasting fragrance and care for fabrics, held together in the three chambers.

Unilever have 9 patents in water soluble biobased unit dose format.

The Clorox Company (NYSE: CLX) is a leading multinational manufacturer and marketer of consumer and professional products with about 8,100 employees worldwide and fiscal year 2017 sales of $6.0 billion. Clorox markets some of the most trusted and recognized consumer brand names, including its namesake bleach and cleaning products; Pine-Sol® cleaners; Liquid Plumr® clog removers; Poett® home care products; Fresh Step® cat litter; Glad® bags, wraps and containers; Kingsford® charcoal; Hidden Valley® dressings and sauces; Brita® water-filtration products; Burt’s Bees® natural personal care products; and RenewLife® digestive health products.

Clorox has added biodegradable wipes to its line of Green Works cleaners and announced how much it is giving the Sierra Club as part of their marketing relationship.

Clorox have 3 patents in water soluble biobased unit dose format.

Technology Domain Specific Research (know-how, industry solutions)

Upcoming Technologies by Patent Assignees

JIANGMEN PROUDLY WATER SOLUBLE PLASTIC has developed a film bag processing mechanism and film bag sell machine. The film bag processing mechanism includes a heating station with at least one heating workpiece arranged in the heating station, where the heating workpiece is used for heating a local area or a whole area of the film bag so as to improve the flexibility of the film bag. The film bag is composed of water-soluble material such as polyvinyl alcohol and modified products, chitosan and derivatives thereof, polyacrylamide and derivatives thereof, starch grafted acrylamide, cellulose grafted acrylamide. The process improves the pliability and reduces brittle failure tear under the low humidity environment.

Source- CN215101047U (Published on December 10, 2021)

PROCTER & GAMBLE has developed a water-soluble unit dose article containing a liquid laundry detergent composition and a water-soluble film and preparation method. The water soluble film is composed of starches, modified starches, crosslinked polyvinylpyrrolidone, crosslinked cellulose, a polyvinylalcohol homopolymer or a polyvinylalcohol copolymer or a mixture thereof and the a liquid laundry detergent includes a first and second anionic surfactant, a non-ionic surfactant or a mixture thereof. Further, the method includes deforming the first water-soluble film to create an open compartment, then dosing a liquid laundry detergent composition from a nozzle into the open compartment followed by closing the filled open compartment with the second water-soluble film and sealing the first and second water-soluble films together. This method reduces string breaking time and increase the manufacturing speeds.

Source- US20210380902A1 (Published on December 9, 2021)

NORDICCAN has developed a pouch designed for administration of an active ingredient in the oral cavity. The pouch containing an appropriate amount of one or more cannabinoids, has a matrix composition which includes powdered granules of cannabinoids placed inside a water soluble composition. The water soluble composition includes a sugar alcohol such as sorbitol, erythritol, xylitol, lactitol, maltitol, mannitol, hydrogenated starch hydrolysates, isomalt and any combination thereof. This new formulation helps to achieve a more controllable release of cannabinoids and an essentially complete release of the medication inside the water-soluble carrier.

Source- US11166935B2 (Published on November 9, 2021)

CXS has developed a powder cleaning agent composition packed in a water-soluble pouch and the water soluble pouch is composed of a water-disintegrating film. This film is further composed of water soluble material including polyvinyl alcohol-based, polyvinylpyrrolidone-based, methylcellulose-based, polyethylene oxide-based, gelatin-based, ethylcellulose-based, and hydroxypropylcellulose, starch-based, sugar-based along with plasticizer such as glycerin. In addition, the water-disintegrating film includes a water-soluble paper coated with a water-soluble plastic resin. The cleaning agent does not leave white residue when dissolving it in a liquid, while having powder fluidity capable of efficiently packing into a pouch.

Source- JP2021178940A (Published on November 18, 2021)

Emerging trends in Bio-based water-soluble/water-dispersible films for applications unit dose formats

- The global water soluble films market is estimated to grow from USD 364 million in 2020 to USD 476 million by 2025, at a CAGR of 5.5%. In a quest for a novel replacement of conventional plastic bags which multiple environmental concerns, we have shifted from plastic based packaging to a more sustainable, environment friendly, bio-based water soluble films for packaging industry. These films are applicable to wide range of fields such as detergent packaging, water treatment chemical packaging, food packaging, agrochemical packaging, and pharmaceutical packaging. The detergent packaging estimated to account for the largest share of the overall water soluble films market, in terms of value, between 2020 and 2025.Cold water soluble films expected to be the fastest-growing type of the water soluble films market, in terms of value, between 2020 and 2025.

- North America region is the expected to lead the single dose detergent packaging market attributed to the consumer lifestyle and consumer preference in the region.

- Pods are relatively novel segment in the single dose detergent packaging market. A company called Dropps developed a single-unit dose laundry detergent pod eliminate all the unnecessary additives, fillers and water to create a efficient pod product which in turn resulted in a major cost and emissions savings. Dropps laundry detergent pods weigh in at just 10g and feature a single layer of dissolvable film. In comparison, other competitors in the space weigh in at 25g+ with multi-chamber products. pods are composed using a water-soluble film membrane made from poly-vinyl alcohol (PVOH). Once the film dissolves in a washer, it dissolves and the remaining from poly-vinyl alcohol is breaking down into carbon dioxide and water by the action of water stream and microorganisms.

- Notpla is a packaging solutions company that offers innovative products that are plant based or seaweed-based film and waste-free. These products are completely biodegradable and naturally break down in a few weeks. For example, they have developed encapsulated condiments using their bio-based films. Another product called Ooho can hold liquids such as water or juice in a dissolvable pod (a single-use Solo cup in sight). The company has also developed a bio-based plastic film to replace the plastic wrap in residential and commercial kitchens. They offer both hot water and cold water soluble solutions.

- French startup Lactips uses milk proteins as its raw material to produce a clean and biodegradable plastic that is used to design water-soluble and sustainable packaging that can replace single-use plastics.

- Kuraray partnered with detergent industry giants to produce sustainable and biodegradable unit dose product. The films are made of water-soluble material and finds application in laundry packs or dishwasher tabs enclosing powders, liquid concentrates or composite materials. They also producing food grade certified films.

- Decomer is a Estonia based start-up company that produces edible and water-soluble packaging made from plant protein. The company is also developing blendable packages for smoothies, water-soluble flavour packets (for soups like ramen), and single-use detergent pods for laundry.

- Hydroxypropyl methylcellulose or soy protein isolate-based edible, water-soluble, and antioxidant films developed by Rachel A. Rosenbloom and Yanyun Zhao, for safflower oil packaging. The composition further includes 0.1 or 0.2% DL-α-tocopherol acetate (VE) and 0 or 0.25% oleic acid, 2, 4, or 6% cellulose nanocrystals (CNCs, w/w dry weight polymer). HPMC-based films achieved full dissolution in water at <55 °C under 5 min and cellulose nanocrystals improves film mechanical and barrier properties. Oleic acid significantly increased (P < 0.05) heat saleability. The developed films are a promising packaging alternative to decrease plastic waste, extend shelf life of lipid-based foods, and increase consumer convenience. These films can be used as single-use pouches of sauce or oil are common for seasoning instant and frozen foods. The biopolymeric films and pouches developed unique properties from water solubility across a wide range of temperatures, resistance to oil, high oxygen barrier, and good heat sealability.

- Fast dissolving films developed by Vaishali Y. Londhe and et. by using hydroxypropyl methylcellulose, polyvinyl alcohol, glycerol, sorbitol, menthol and an alkalizer as raw ingredients and formulated using solvent casting method. A fast dissolving film of telmisartan was formulated with a good dissolution profile along with elegant appearance and other physical characteristics like tensile strength, % elongation, folding endurance.

- Chicken protein isolate (CPI)/fish skin gelatin (GE) blend films containing gallic acid (GA) or tannic acid (TA) developed by Krisana Nilsuwan and et. The prepared film was studied for its physical properties. It was found that incorporating phenolics generally increased (p < 0.05) tensile strength and elongation at break, and decreased (p < 0.05) solubility of resulting films. Incorporation of 0.75 % gallic acid improved mechanical properties and antioxidant activity of CPI/GE blend film, thus highlighting the potential of the resulting pouches as active food packaging.

- Soluble sachets with potential application in powdered foods container or oil containers and capsules for instant coffee machines. The soluble film developed by Gabriel da Silva Filipini and et. Includes a blend of collagen, methylcellulose, and whey protein and produced by the casting technique. Methylcellulose films presented excellent technological properties, such as total solubility in water, high tensile strength (15.78 MPa), transparency (30.4%), and good barrier to water vapor (0.43 g·mm/h·m2·kPa). Collagen and whey protein increase in tensile strength, barrier, and thermal properties.

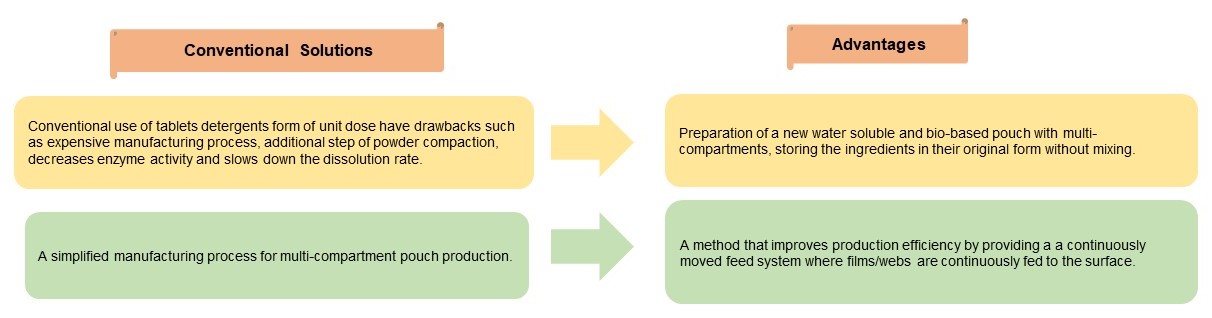

Water Soluble Multi-Compartment Pouch

Solution

Procter and Gamble Co (P&G) founded in 1837, is an American consumer goods giant specializing in a wide range of personal care and hygiene products. The company’s headquarters is in Cincinnati and it is well-known to manufacture household products including Crest, Charmin, Tide, Oral-B, Bounty, Febreze, Downy, and Gain. In 1980s, P&G launched Cheer Power Pouches, a single-dose laundry paste packaged in a water-soluble film.

They have addressed the issue of utilization of different detergent active or auxiliary ingredients such as powders, paste and liquids, in a single unit dose format with improved utilization efficiency. Such ingredients are incompatible and usually present in different physical forms. Therefore, there is still a need for an improved water-soluble multi-compartment unitised dose capable of fitting the dispensers of different dishwashing machine types. There is also need for a simplified manufacturing process for multi-compartment pouch production and for multi-compartment pouches with improved strength, handling and dissolution characteristics as well as excellent aesthetics.

Procter and Gamble Co (P&G) filed a patent titled, “Detergent products, methods and manufacture” on August 23, 2018, that provides a water-soluble pouch suitable for use in machine dishwashing and which includes plurality of compartments in generally superposed or superposable relationship and each compartments containing one or more detergent active or auxiliary components. The pouch obtained has a final volume of from about 5 to about 70 ml and a longitudinal/transverse aspect ratio in the range from about 2:1 to about 1:8. The water-soluble pouch allows for optimum delivery of dishwashing detergent. Further, the patent discloses a optimized method of manufacturing for the same. US10889786B2

Procter and Gamble Co (P&G) has collaborated with MonoSol, a Kuraray Company to develop a mini dual-compartmented packets for automatic dishwashing detergent in 2003, which are made with a water-soluble film roll-stock. The cold-water-soluble film packets hold concentrated, powdered Cascade automatic dishwasher detergent in one compartment and blue, liquid Dawn® grease cutter in the other, providing consumers with one product that does the work of multiple products and the convenience of a single unit-dose packet.

Procter and Gamble Co (P&G) and MonoSol, launched Tide Pods in 2012. Tide Pods is a single-use packet with three chambers that hold liquid detergent, a stain fighter and a brightener. For the project, MonoSol developed a new proprietary film that dissolves rapidly in the wash, even in cold water, yet holds up to wet hands.

Clorox 2 Packs from Clorox, OxiClean Max Force Power Paks from Church & Dwight, and Tide Stain Release from P&G are all oxygen-bleach-based stain removal capsules packaged in polyvinyl alcohol film pouches.

Some key personnel includes Jon R. Moeller (CEO of P&G), Victor Aguilar (Chief Research, Development and Innovation Officer), Laura Becker (General Manager P&G Global Business Development),Tom Yogan (Director of Research & Development at MonoSol)

Production method

The research line has developed a machine dishwashing product in the form of multi-compartment, bio-based and water soluble pouch for holding one or more detergent active components or detergent auxiliaries. These plurality of compartments in generally superposed or superposable relationship and can be symmetrically arranged one above another or side by side for convenient disposition. This multi-compartment arrangement is advantageous since it reduces surface area of composition exposed to the surrounding environment, therefore reducing the possibility of picking up moisture from the surroundings. Each off these compartments are separated by one or more internal partitioning walls. Each internal partitioning wall of the water-soluble multi-compartment pouch is secured to an outer or side wall of the pouch along a single seal line.

The pouch is made of a pouch material which is soluble or dispersible in water, and has a water-solubility of at least 50% and the pouch material is polymeric material formed into a film or sheet. Preferred polymers, copolymers or derivatives suitable for use as pouch material are selected from polyvinyl alcohols, polyvinyl pyrrolidone, polyalkylene oxides, acrylamide, acrylic acid, cellulose, cellulose ethers, cellulose esters, cellulose amides, polyvinyl acetates, polycarboxylic acids and salts, polyaminoacids or peptides, polyamides, polyacrylamide, copolymers of maleic/acrylic acids, polysaccharides including starch and gelatine, natural gums such as xanthum and carragum. The level of polymer in the pouch material, for example a PVA polymer, is at least 60%.

Mixtures of polymers are used for the preparation of water soluble pouch to control the mechanical and/or dissolution properties of the compartments or pouch. For example, hydrolytically degradable and water-soluble polymer blends. The pouch material includes other additives such as glycerol plasticisers.

The pouch material film can be obtained by casting, blow-moulding, extrusion or blown extrusion of the polymeric material.

The manufacturing method includes:

- Forming the first and/or second moving webs involves continuously feeding a water-soluble film onto a horizontal endless surface, in horizontal rectilinear motion. The width of horizontal portion of the endless surface is from 6 to 10 or even 9 meters and speed between 1 and 80 m/min.

- The horizontal motion allow formation of the web of pouches followed by filling of the pouches and superposition of the second moving web of pouches.

- Sealing the two moving webs and cutting to separate the superposed webs into a plurality of multi-compartmental pouches.

- Pouches are removed from the surface and the surface will rotate around an axis perpendicular to the direction of motion, typically about 180 degrees to starts again.

The surface is removably connected a rotating belt, for example a conveyer belt or platen conveyer belt. This makes the process a continuously moved feed system. For example, the use of a zero-elongation chain system, which drives the surface or the belt connected to the surface. The surface is further connected to two or more vacuum systems to provide pressure for varying duration. For example, the vacuum drawing the film into the mould can be applied only for 0.2 to 5 seconds under-pressure of between −100 mbar to −1000 mbar.

The mold used can have any shape, length, width and depth, depending on the required dimensions of the pouches. For example, it may be preferred that the volume of the final pouches is between 5 and 300 ml.

The feeding of the film onto or on top of the surface and onto the horizontal portion is done continuously. This is achieved by using rollers for film unwinds.

The rollers rewind the film with a speed of at least 100 m/min.

Once on the surface, the film is held in position using vacuums (under pressure) on the edges of the surface. The vacuum is applied along the edges of the film. This method is suitable even if the film width is larger than the surface, so this system is more flexible than the use of grips of clips. The surface is connected to vacuums via holes called as vacuum chambers. These holes are preferably along the edges of the surface. Some of the holes are close to the mould edges, to reduce wrinkling in the area around the mould edges. The diameter of these holes are in range of 0.1 mm to 20 mm.

The open pouches can be formed by any of the following methods: vacuum or under-pressure to draw the film into the moulds, heating and/or wetting the film and thereby making the film more flexible or combinations of both.

Filling unit: The filling of the first and second webs of open pouches can be done by flood dosing, continuous motion in line filling or reciprocating-motion-filling method. The filling unit or station used in the process uses a flow meter and/or positive displacement pump to dose the correct amounts or volumes of product per open pouch.

Heat sealing: Sealing temperatures are from 50 to 300° C., or even from 80 to up to 200° C., depending on the film material.

Cutting: The superposed and sealed webs of pouches can then be cut by a cutting device.

Comments

- The compositions of examples 1 to 4 are introduced in a two compartment layered PVA rectangular base pouch. The dual compartment pouch is made from a Monosol M8630 film.

- The pouch dimensions under 2 Kg load are: length 3.7 cm, width 3.4 cm and height 1.5 cm.

- Compartments made of films substantially insoluble in cold water and soluble in warm water and which house liquids.

- Disintegrating agents such as effervescence sources, water-swellable polymers or clays are present in the pouch itself.

- Pouch allows for a delayed release of the liquid composition providing optimised use of the detergent composition.

Applications

- The water soluble multi-compartment pouch adapted to fit the dishwasher dispenser and to deliver product into the pre-wash, main wash and/or post-rinse cycles of the dishwashing machine.

- The pouch contains a cleaning composition for release on dissolution of the pouch.

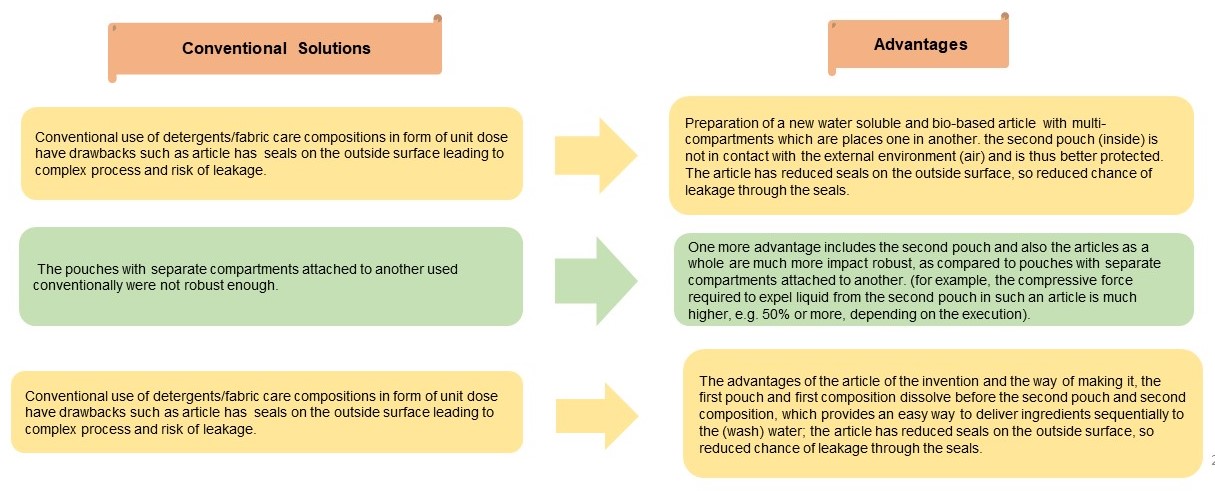

Articles containing Enclosed Compositions

Solution

Procter and Gamble Co (P&G) founded in 1837, is an American consumer goods giant specializing in a wide range of personal care and hygiene products. The company’s headquarters is in Cincinnati and it is well-known to manufacture household products including Crest, Charmin, Tide, Oral-B, Bounty, Febreze, Downy, and Gain. In 1980s, P&G launched Cheer Power Pouches, a single-dose laundry paste packaged in a water-soluble film.

They have addressed the issue of utilization of different detergent active or auxiliary ingredients such as powders, paste and liquids, in a single unit dose format with improved utilization efficiency. Such ingredients are incompatible and usually present in different physical forms. Therefore, there is still a need for an improved water-soluble multi-compartment unitised dose capable of fitting the dispensers of different dishwashing machine types. There is also need for a simplified manufacturing process for multi-compartment pouch production and for multi-compartment pouches with improved strength, handling and dissolution characteristics as well as excellent aesthetics.

Procter and Gamble Co (P&G) has collaborated with MonoSol, a Kuraray Company to develop a mini dual-compartmented packets for automatic dishwashing detergent in 2003, which are made with a water-soluble film roll-stock. The cold-water-soluble film packets hold concentrated, powdered Cascade automatic dishwasher detergent in one compartment and blue, liquid Dawn® grease cutter in the other, providing consumers with one product that does the work of multiple products and the convenience of a single unit-dose packet.

Procter and Gamble Co (P&G) filed a patent titled “Articles containing enclosed compositions” on July 24, 2001, that provides an article comprising two water soluble pouches suitable for use in laundary and which includes plurality of compartments in generally superposed or superposable relationship and each compartments containing one or more detergent active or auxiliary components. This new sachet or article of the invention comprises a first pouch made from a water-reactive (soluble) film, which comprising in its interior a first composition and an another pouch made also made from a water-reactive (soluble) film, containing a second composition. The second pouch is completely enclosed by the first pouch. US6727215B2

Procter and Gamble Co (P&G) and MonoSol, launched Tide Pods in 2012. Tide Pods is a single-use packet with three chambers that hold liquid detergent, a stain fighter and a brightener. For the project, MonoSol developed a new proprietary film that dissolves rapidly in the wash, even in cold water, yet holds up to wet hands.

Clorox 2 Packs from Clorox, OxiClean Max Force Power Paks from Church & Dwight, and Tide Stain Release from P&G are all oxygen-bleach-based stain removal capsules packaged in polyvinyl alcohol film pouches.

Some key personnel includes Jon R. Moeller (CEO of P&G), Victor Aguilar (Chief Research, Development and Innovation Officer), Laura Becker (General Manager P&G Global Business Development),Tom Yogan (Director of Research & Development at MonoSol).

Production method

The research line has developed an improved way of delivering a sachet comprising two compartments or more. for example different compositions per compartment. The article of the invention combines all advantages of single compartment pouches with the advantages of dual (or more) compartment pouches and these resulting pouches are filled by at least 90% by volume.

The second pouch is not in contact with the external environment (air) and is thus better protected; the first pouch and first composition dissolve before the second pouch and second composition, which provides an easy way to deliver ingredients sequentially to the (wash) water; the article has reduced seals on the outside surface, so reduced chance of leakage through the seals; ease of making these new articles; reduced process complexity (compared to attaching compartments to one another); and it is even possible to reduce the amount of pouch material needed. Also, the second pouch and also the articles as a whole are much more impact robust, as compared to pouches with separate compartments attached to another (for example, the compressive force required to expel liquid from the second pouch in such an article is much higher, e.g. 50% or more, depending on the execution).

The sachet/article is made of material which is soluble or dispersible in water, the sachet material is polymeric material e.g. polymers which are formed into a film or sheet. .Prefered polymers are selected from polyvinyl alcohols, polyvinyl pyrrolidone, polyalkylene oxides, acrylamide, acrylic acid, cellulose, cellulose ethers, cellulose esters, cellulose amides, polyvinyl acetates, polycarboxylic acids and salts, polyaminoacids or peptides, polyamides, polyacrylamide, copolymers of maleic/acrylic acids, polysaccharides including starch and gelatine, natural gums such as xanthum and carragum. More preferably the polymer is selected from polyacrylates and water-soluble acrylate copolymers, methylcellulose, carboxymethylcellulose sodium, dextrin, ethylcellulose, hydroxyethyl cellulose, hydroxypropyl methylcellulose, maltodextrin, polymethacrylates, most preferably polyvinyl alcohols, polyvinyl alcohol copolymers and hydroxypropyl methyl cellulose (HPMC). The pouch material includes other additives such as plasticisers (for example water glycerol, ethylene glycol, diethylene glycol, propylene glycol, sorbitol and mixtures thereof), stabilizers, disintegrating aids, etc.

Mixtures of polymers can also be used. This may in particular be beneficial to control the mechanical and/or dissolution properties of the compartments or sachets.

The sachet material film can be obtained by casting, blow-moulding, extrusion or blown extrusion of the polymeric material.

The manufacturing method includes:

The article of the invention is made by introducing a second pouch containing a composition in a first pouch such that the first pouch encloses the second pouch completely by the process of vacuum-forming or thermoforming.

- Formation of the second pouch in open form, adding the second composition in said open second pouch and closing this to obtain the second pouch .

- Formation of the first pouch in open form, adding the second pouch and the first composition to the open first pouch and closing this first pouch to obtain the article.

The mold used consists of a cylindrical shape and has a diameter of 10 mm and a depth of 8 mm. The mould has some holes in the mould material to allow a vacuum to be applied.

- Thermo-forming typically involves the step of formation of an open pouch in a mould under application of heat, which allows the material used for the pouch to take on the shape of the mould. Vacuum may be concurrently or separately used herein as well. Vacuum-forming typically involves the step of applying a (partial) vacuum on a mould which sucks the material into the mould and ensures the material adopts the shape of the mould.

- Then, the open pouch in the mould is filled with the composition, and in the case of the first pouch, with the second pouch. The open pouch is then closed, typically with another piece of material, and sealed. The sealing can be done by any known method, for example by heat sealing, wetting, use of gluing agent, compression, or combinations thereof.

This process can be modified by using other methods of forming the shape of the Sachets, other types of film, other sizes of mould, sealing methods, more individual pouches etc.

Comments

- The first pouch is made of a material which releases the first composition significantly earlier than the second pouch releases the second composition. Preferably, the first composition is a builder composition, while the second composition is a fabric care composition, fabric cleaning composition, or hard surface cleaning composition.

- First pouch which quickly dissolves and/or ruptures to release the first composition, and a second pouch which dissolves and/or ruptures more slowly to release the second composition. This arrangement provides especially useful benefits, such as allowing sequential water softening and subsequent cleaning.

- The material used for making pouches is preferably elastic, to ensure tight packing and fixation of the composition therein during handling, e.g. to ensure no (additional) head space can be form after closure of the compartment. Preferred stretchable materials have a maximum stretching degree of at least 150%, preferably at least 200%, and more preferably of at least 400%.

- The first composition may be a liquid, non-aqueous liquid, gel, etc., which is transparent, so that the second pouch is visible.

Applications

- The water soluble two compartment pouch is applicable for fabric cleaning compositions for laundry ( in a washing machine), dish washing or hard surface cleaning or fabric care compositions.

- The article/ scahet contains two pouches one in another containing cleaning composition for release on dissolution of the pouch.

Unit dose article for packaging personal care products

Solution

MonoSol, LLC is a division of Tokyo-based Kuraray Group, one of the world’s leading specialty chemical companies. Headquartered in Merrillville, Indiana, MonoSol is best known for its water-soluble, biodegradable films used to make laundry and dishwashing packets marketed by major consumer products companies and private label brands around the world. Its growing portfolio of applications includes detergents, agrochem, solid surface, composites and embroidery, as well personal care products, food ingredients, water treatment chemicals, transfer printing and more.

MonoSol’s water-soluble films production facility was planned for construction in three phases. The first phase, which has commenced operations, included the installation of one manufacturing line for the production of water-soluble films and other packaging materials. A second production line will be added by 2017, while the plant will operate at its full capacity by 2020. The existing production line features latest and innovative technology to produce next-generation, high-quality, water-soluble films. The plant will produce MonoSol’s film-based products marketed under brand names, including MonoDose, Vivos, AquaFilm, BadgeMaster, Dissolvo Sack, and MonoFilm.

MonoSol manufactures polyvinyl alcohol (poval) films for industrial applications, including packaging films for unit-dose detergent products and agrochemicals, dyes and mold-release films for synthetic marble. By acquiring MonoSol, Kuraray expanded its array of poval films to a wider range of industrial applications.

MonoSol, LLC , with the power of water-soluble technology and their brilliant team of chemists, engineers and innovators, create safer, simpler and more sustainable solutions for a range of industries. The films made for packaging are tough, elastic and resilient to deliver the product safe and securely.

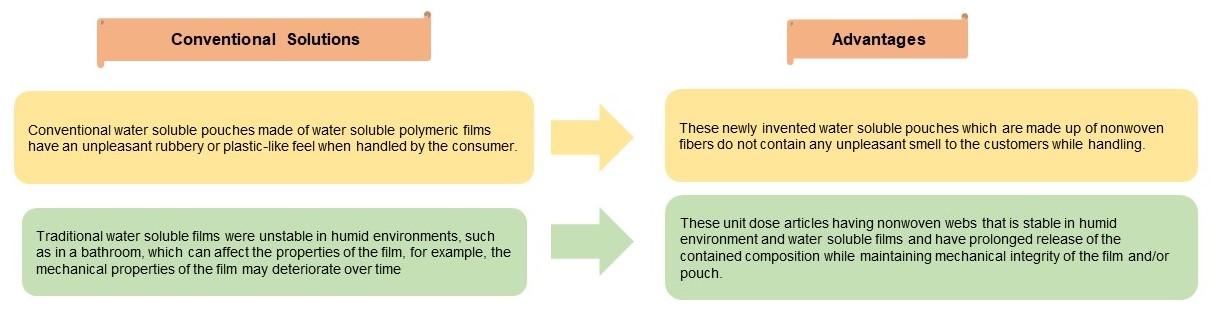

MonSol LLC filed a patent titled “Unit dose article for packaging personal care products “on December 02, 2020 that provides a unit dose articles having nonwoven webs and water soluble films, as well as related compositions. More particularly, the disclosure relates to unit dose articles for packaging personal care products for prolonged release. unit dose article comprising a compartment comprising a water soluble film in the form of a pouch defining a first interior pouch volume, the water soluble film comprising a water soluble resin; a nonwoven web in the form of a pouch encompassing the water soluble film, the nonwoven web comprising a plurality of fibers comprising a fiber type comprising a blend of PVOH homopolymer fiber forming materials and a fiber type comprising a non-water soluble, biodegradable fiber forming material; wherein the water soluble film and the nonwoven web form a laminate and a personal care composition is contained by the unit dose article and comprises a surfactant. WO2021113294A1

MonoSol’s films for personal care create innovative and sustainable solutions. Transforming your personal care and cosmetics products by packaging them in water-soluble and biodegradable film made with natural ingredients Creating a more concentrated cosmetic and personal care product reduces transportation emissions, saves water and eliminates unnecessary filler ingredients. A quick splash of water can transform a single-use pouch into an on-the-go hand wash, shampoo, conditioner or shaving cream.

The intellectual property of MonoSol includes 129 registered patents primarily in the 'Animal And Vegetable Oils, Fats, Fatty Substances And Waxes; Fatty Acids Therefrom; Detergents' category, according to IPqwery. Additionally, MonoSol has registered 43 trademarks with the most popular class being 'Rubber and plastic goods; packing, stopping and insulating materials', according to IPqwery.

The Kuraray Group and MonoSol announced that P. Scott Bening will pass the leadership of MonoSol to Christian Herrmanns. Effective January 1, 2022, Mr. Herrmanns will become President of MonoSol LLC and General Manager of the MonoSol Division of Kuraray Group. Mr. Bening, who led the growth.

MonoSol announced it will raise the price for water-soluble films made in the United States by a minimum of 6 percent beginning January 10, 2022, or as contracts allow.

Production method

Unit dose article comprising a first compartment, comprising: a water soluble film in the form of a pouch defining a first interior pouch volume, the water soluble film comprising a water soluble resin; a nonwoven web in the form of a pouch defining a second interior pouch volume encompassing the water soluble film, the nonwoven web comprising a plurality of fibers; and a first composition contained by the first compartments, wherein the water-soluble film and the nonwoven web are in the form of a laminate and have a degree of lamination in a range of about 5% to about 100%.

In general, the unit dose article can include a nonwoven web and a water soluble film, wherein the nonwoven web can include a plurality of fibers including one or more water soluble fiber types, one or more non-water soluble fiber types, a blend of a water soluble fiber type and a non-water soluble fiber type, one or more water-soluble fiber forming materials, one or more non-water soluble fiber forming materials, or a blend of water soluble fiber forming materials and non-water soluble fiber forming materials. The water soluble film can include a water soluble resin, optionally including one or more water soluble polymers.

Water soluble polymers for use in the water soluble fibers, nonwoven webs, and water soluble films include, but are not limited to, a polyvinyl alcohol, polyacrylate, water-soluble acrylate copolymer, polyvinyl pyrrolidone, polyethyleneimine, pullulan, water-soluble natural polymers including, but not limited to, guar gum, gum Acacia, xanthan gum, carrageenan, and starch, water-soluble polymer derivatives including, but not limited to, modified starches, ethoxylated starch, and hydroxypropylated starch, copolymers of the forgoing and combinations of any of the foregoing.

The nonwoven web prepared from a polyvinyl alcohol fiber will have higher biodegradation activity levels relative to a water soluble film prepared from a similar polyvinyl alcohol polymer, due to the increase in the polymer surface area provided by the nonwoven web, relative to a film.

The pouch material include other materials such as auxiliary agents such as, plasticizers, plasticizer compatibilizers, surfactants, lubricants, release agents, fillers, extenders, cross-linking agents, antiblocking agents, antioxidants, detackifying agents, antifoams, nanoparticles such as layered silicate-type nanoclays (e.g., sodium montmorillonite), bleaching agents (e.g., sodium metabisulfite, sodium bisulfite or others), aversive agents such as bitterants (e.g., denatonium salts such as denatonium benzoate, denatonium saccharide, and denatonium chloride; sucrose octaacetate; quinine; flavonoids such as quercetin and naringen; and quassinoids such as quassin and brucine) and pungents (e.g., capsaicin, piperine, allyl isothiocyanate, and resinferatoxin), and other functional ingredients, in amounts suitable for their intended purposes.The film can have any suitable thickness, and a film thickness of about 76 microns.

The water-soluble film can further have a residual moisture content of at least 4 wt. %, for example in a range of about 4 to about 10 wt. %, as measured by Karl Fischer titration.

The molds, in which packets may be made, can have any shape, length, width and depth, depending on the required dimensions of the pouches. For example, the volume of the final pouches may be about 5 ml to about 300 ml, or about 10 ml to 150 ml, or about 20 ml to about 100 ml, and that the mold sizes are adjusted accordingly.

Methods of Preparing Fibers includes Wet Cooled Gel Spinning. The plurality of water soluble fibers can include water soluble fibers prepared according to a wet cooled gel spinning process, the wet cooled gel spinning process including the steps of:

- Dissolving the water soluble polymer (or polymers) in solution to form a polymer mixture, the polymer mixture optionally including auxiliary agents;

- extruding the polymer mixture through a spinneret nozzle to a solidification bath to form an extruded polymer mixture;

- passing the extruded polymer mixture through a solvent exchange bath;

- optionally wet drawing the extruded polymer mixture; and

- finishing the extruded polymer mixture to provide the water soluble fibers.

The solvent in which the water soluble polymer is dissolved can suitably be any solvent in which the water soluble polymer is soluble. Eg dimethyl sulfoxide (DMSO).

Finished fibers are sometimes referred to as staple fibers, shortcut fibers, or pulp.

Further finishing includes drying the extruded polymer mixture. finishing includes cutting or crimping the extruded polymer mixture to form individual fibers. Wet drawing of the extruded polymer mixture can provide a substantially uniform diameter to the extruded polymer mixture and, thus, the fibers cut therefrom.

Thermoforming : A thermoformable nonwoven web, film, or laminate is one that can be shaped through the application of heat and a force. Thermoforming a nonwoven web, film, or laminate structure is the process of heating the nonwoven web, film, or laminate structure, shaping it (e.g. in a mold), and then allowing the resulting nonwoven web, film, or laminate to cool, whereupon the nonwoven web, film, or laminate will hold its shape, e.g. the shape of the mold.

Sealing: Any suitable method of sealing the packet and/or the individual compartments thereof may be utilized. Non-limiting examples of such means include heat sealing, solvent welding, solvent or wet sealing, and combinations thereof. Typically, only the area which is to form the seal is treated with heat or solvent.

Cutting: Formed pouches may be cut by a cutting device. Cutting can be accomplished using any known method. It may be preferred that the cutting is also done in continuous manner, and preferably with constant speed and preferably while in horizontal position. The cutting device can, for example, be a sharp item, or a hot item, or a laser, whereby in the latter cases, the hot item or laser ‘burns’ through the film/sealing area.

Comments

- The unit dose article comprises at least two compartments, at least a portion of one nonwoven web pouch is soluble in water at a temperature in a range of about 10°C to about 20°C .

- The compartments of multi-compartment pouches may be of the same or different size(s) and/or volume(s). The compartments of the present multi-compartment pouches can be separate or conjoined in any suitable manner.

- The manufacturing process including sealing comprises solvent sealing.

Applications

- The unit dose made up of water soluble film having multiple compartments is used for personal care products.

- The unit dose packaging that is pleasant to handle, can have prolonged release of the contained composition, and can withstand humid environments, like a bathroom.

Cold Water Soluble Containerization System

Solution

Rhône-Poulenc SA founded in 1801, a former French chemical manufacturer and leading producer of organic chemicals, synthetic fibers, and pharmaceuticals. It merged with Hoechst Aktiengesellschaft in 1999 to create the French-German pharmaceutical firm Aventis. In 1928, it merged with Établissements Poulenc Frères (“Poulenc Brothers”), the pharmaceutical house established by Camille Poulenc (1864–1942), the founder of the French pharmaceutical industry. The new Société des Usines Chimiques Rhône-Poulenc develop pharmaceutical specialties and new techniques for the manufacture of synthetic textiles. The specialty chemicals division of Rhone-Poulenc Inc. produces products from food additives to water-soluble polymers.

These water-soluble polymer based products such as packaging for pesticide gels that would dissolve in water before being applied to crops, were launched in 1993.

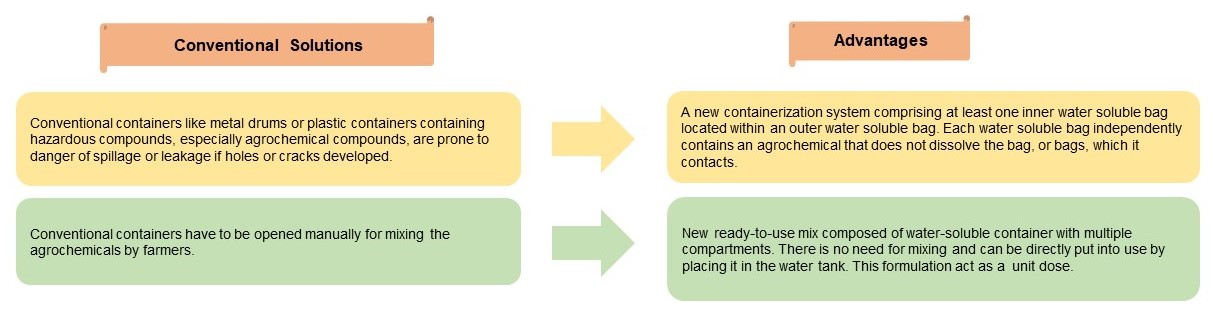

It is addressing the need of a ready-mix container containing more than one agrochemical by farmers to treat their crop. One of the main drawbacks of using different agrochemicals together, is they tend to agglomerate together when mixed and might by incompatible with the water-soluble film bag itself. This can lead to difficulties in handling, transportation and storage of such liquid compositions. Leakage of toxic and hazardous chemicals can further creates damage to the environment.

Rhône-Poulenc SA filed a patent titled, “Containerization system” on March 27, 1992, that providesa containerization system having one inner water soluble bag located within an outer water soluble bag. Each water soluble bag independently contains an agrochemical that does not dissolve the bag, which it contacts. US5253759A

The research line has developed a new containerization system to contain agrochemicals which is safe for everybody and easier for the farmer to manipulate directly into the mixing tanks. This new containerization system containing agrochemicals is readily, rapidly and easily soluble and/or dispersible in water. This bag is designed to be much condensed as possible, using the least amount of space. This patent also discloses a new method to contain more than one hazardous compounds e.g. agrochemicals which diminishes the risks of pollution. The container system contains incompatible agrochemicals and enables such chemicals to be easily and homogeneously dispersed in water.

The new containerization system for agrochemicals which eliminates or reduces the disagreeable odors or odor problems of odoriferous chemicals.

Production method

The “poly-bag system” including an inner water soluble or water dispersible bags containing a hazardous compound or product, disposed inside an outer water soluble or water dispersible bag containing another hazardous compound or product. This poly-bag system itself contained in an external water insoluble container, such as a rigid or semi-rigid box.

The ratio of volume between the outer bag and the inner bag is more than 2:1.

Both outer and inner bags can float or sink when put into water, such as the tank of water that a farmer uses for mixing and spraying. In such arrangement, the floating bag contains a wettable powder or water dispersible granules.

The bags are made of a polymeric water soluble film and the thickness of this film is generally between 20 and 100 microns. The bags are soluble in cold-water and the polymeric material constituting the wall of the bags may be the same or may be different for the two bags. Cold water soluble means water at temperature lower than 35° C. The bags composed of enveloping films are water soluble (or possibly water dispersible) materials which are insoluble in the organic solvents used to dissolve or disperse the agrochemical active ingredient.

The enveloping films can be selected from polyethylene oxide, such as polyethylene glycol; starch and modified starch; alkyl and hydroxyalkylcellulose, such as hydroxymethylcellulose, hydroxyethylcellulose, hydroxypropyl cellulose; carboxymethylcellulose; polyvinylethers such as poly methyl vinylether or poly(2-methoxyethoxyethylene); poly(2,4-dimethyl-6-triazinylethylene; poly(3-morpholinyl ethylene); poly(N-1,2,4-triazolylethylene); poly(vinylsulfonic acid); polyanhydrides; low molecular weight melamine-formaldehyde resins; low molecular weight ureaformaldehyde resins; poly(2-hydroxyethyl methacrylate); polyacrylic acid and its homologs. Preferably the enveloping film comprises or is made from polyvinylalcohol (PVA).

The outer bag may contain adjuvants and plasticizers for the cold water soluble bag.

The agrochemicals in the bags are in solid or liquid or gel a concentrated form.

The preparation or manufacturing of the containerization system comprises the following steps:

- The first bag (inner bag) is prepared from a water soluble film, optionally by partial heat sealing.

- Then it is filled with an agrochemical composition and the bag is finally closed.

- Then the second bag (outer bag) is prepared in a similar manner and filled with an agrochemical composition and inner bag is placed inside the outer bag and sealed by heat sealing method.

Comments

- Less solvent is needed in the formulation of an agrochemical, which is a cost saving both in shipping and manufacturing.

- Agrochemical composition in outer bag has a specific gravity less than 1.

- Agrochemical composition in inner bag has a specific gravity greater than 1.

- The outer bag is preferably not filled to complete capacity to provide shock resistance.

- The inner bag may contain a marker, e.g. a dye.

- No real mixing is needed.

Applications

- Containers suitable for storing, packaging and transporting toxic or hazardous products, e.g. agricultural chemical compounds, such as pesticides and concentrates thereof.

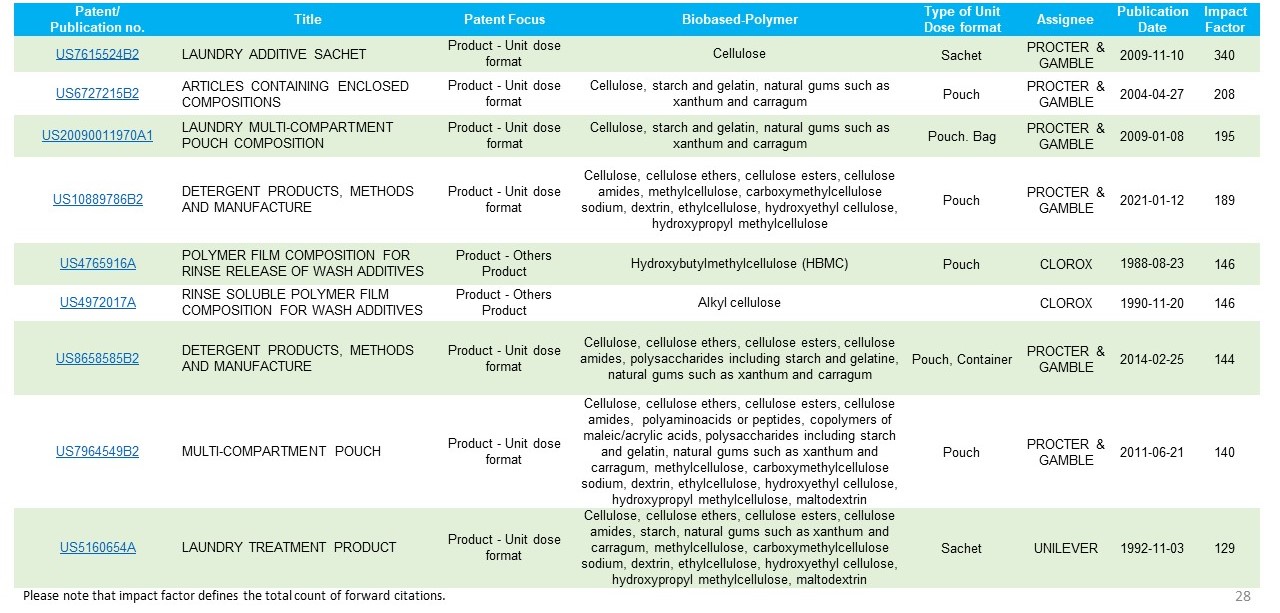

Top Patents based on Impact Factor – Forward Citations

About Effectual Services

Effectual Services is an award-winning Intellectual Property (IP) management advisory & consulting firm offering IP intelligence to Fortune 500 companies, law firms, research institutes and universities, and venture capital firms/PE firms, globally. Through research & intelligence we help our clients in taking critical business decisions backed with credible data sources, which in turn helps them achieve their organisational goals, foster innovation and achieve milestones within timelines while optimising costs.

We are one of the largest IP & business intelligence providers, globally serving clients for over a decade now. Our multidisciplinary teams of subject matter experts have deep knowledge of best practices across industries, are adept with benchmarking quality standards and use a combination of human and machine intellect to deliver quality projects. Having a global footprint in over 5 countries helps us to bridge boundaries and work seamlessly across multiple time zones, thus living to the core of our philosophy - Innovation is global, so are we !!!

Solutions Driving Innovation & Intelligence

Enabling Fortune 500's, R&D Giants, Law firms, Universities, Research institutes & SME's Around The Globe Gather Intelligence That

Protects and Nurtures Innovation Through a Team of 250+ Techno Legal Professionals.