Smart Mining – The Era of Smart Mines

Introduction

The products of the mining industry are vital to our daily lives. They are essential to meeting our daily demands. The demand for minerals grows as a result of the expanding global population and rising living standards. The mining industry continually struggles to meet this demand and the sustainability standards set by policymakers. To overcome these issues, innovation is a crucial tool.

We all benefit from the mining industry's advantages, both economically and in terms of the products we rely on every day. Our modern healthcare system and cell phones both rely on materials that are mined from the earth. Keeping up with technological developments is more important to satisfying market demand and maintaining competitiveness on a global scale as technology develops and is integrated more deeply into many industries.

The mining industry has not historically been viewed favorably by economists studying innovation. In order to take advantage of economies of scale and meet a demand that is mostly, if not entirely, dependent on the price of mining commodities, it is believed that mining enterprises are more likely to be big and capital-intensive. There are minimal incentives for mining companies to stand out through product innovation or branding. The majority of inventions focus on cost-cutting techniques in an effort to increase their meagre profit margins. As a result, mining companies either develop new technologies in-house or incorporate them into the goods and services they buy from specialist vendors.

Comparatively to other sectors of the economy, such as manufacturing or the pharmaceutical sector, the mining sector has historically been seen as a tardy inventor. Yet, in the early half of the 2000s, we saw an increase in the mining industry's innovation activities. Following periods of stagnation and decreasing trends, mining innovation started to increase quickly throughout this time. The types of actors involved in mining innovation have also evolved over time; now, there are far more individuals, research institutions, and universities engaged in mining innovation than there were in the past.

There is mounting evidence that the mining industry is not only innovative but that it has recently become more so. In contrast to other sectors, the mining industry frequently has a disproportionately high concentration of innovative businesses. From the early 2000s, the sector has also seen a remarkable rise in all innovation metrics.

In 2015, about USD 657 million was spent only in Europe on mining research and development (R&D). It is still higher than agriculture (USD 654) and the production of consumer electronics, even though it is still far lower than so-called high-tech industries like pharmaceuticals (USD 10,868 million) or chemical manufacture (USD 7,416 million) in the same year (USD 347 million).

We also see that the mining industry is placing more and more emphasis on intellectual property (IP), notably patents. In the last five years, there have been more mining-related inventions seeking patent protection than there were from 1970 to 2000 combined. In order to further their internationalization plan, large mining organizations and businesses that specialize in mining equipment, technology, and services (METS) are increasingly using IP. Companies in the mining and METS industries operate internationally, and patents may enable them to protect their intellectual property (IP) and to gain access to the information that underlies innovative products and processes.

Mining companies innovate in their goods, manufacturing methods, and organizational procedures just like any other industry. Mining companies carry out research and development (R&D) tasks, purchase off-the-shelf technologies, which are often embodied in machinery and equipment, or purchase disembodied technologies, such as outsourced R&D or other technological services. Unfortunately, evaluating these innovation characteristics is not always simple, and the mining sector is a good example of this.

The mining business is a little different from other economic sectors in terms of product innovation. The discovery of completely new products is relatively uncommon, indicating that mining itself has very little room for product innovation. The finding of new commercial deposits of already-existing items is a crucial component of the mining industry, even though the discovery and development of novel mined products may be uncommon.

The mining sector relies heavily on organizational and process innovation, both of which strive to cut costs. The distinctions between organizational innovation and process innovation are frequently muddled in many different industries. This is unquestionably true for the mining sector. Process innovation often refers to any enhancement of the manufacturing procedure within an industrial facility. They include modifications to the design, equipment, and any production process used to create a good or service. Everything that takes place outside of the manufacturing facility is considered organizational innovation. They encompass advancements in logistics, management, finance, and related fields. Process innovation in the mining industry refers to any improvement taking place on the mine site, whereas organizational innovation refers to any enhancement of activities taking place off the mine grounds. But a number of mining inventions easily meet both criteria. For instance, both at the mine site and elsewhere, new research techniques, like a drone sending photographs to a computing facility, or new transport systems, such a system regulating loading deep into the mine and offloading in a port far away, are likely to be used.

What is Smart Mining ?

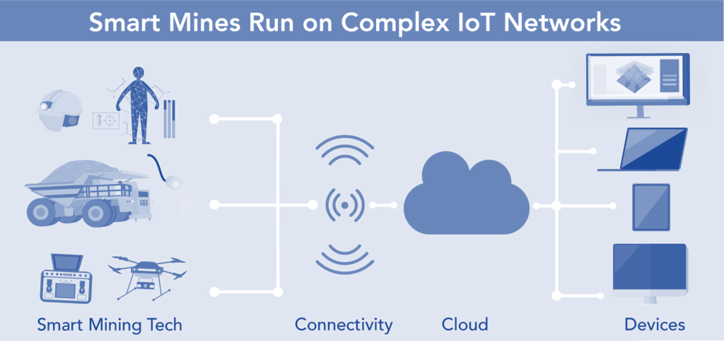

Using networked technologies in the mining industry is known as smart mining. These technologies comprise gadgets like cameras, sensors, and drones that communicate with one another and their surroundings via the Internet. Device networks assist in automating procedures, streamlining operations, gathering useful data, and connecting various mining process components. Smart mining technology help mines operate more effectively, reduce costs, protect workers, and stop unneeded pollution. The Internet of Things (IoT), which is characterized by the utilization of a network of sensors and devices connected via the Internet, is the primary technology driving smart mining. IIoT, which stands for "Industrial Internet of Things," is the name given to IoT when it is used to sectors like mining. By linking devices and removing the need for human engagement in data collecting, IIoT aims to increase industry efficiency.

Just about 0.6 million items worldwide were installed IoT devices in the mining sector in 2018. (Source: Berg Insight). By 2023, this number is anticipated to increase to 1.2 million. It is obvious that the market is seeing benefits from purchasing and building IoT networks. IoT enables connectivity between devices so that information can be exchanged automatically without human intervention between people, machines, and vehicles. This improves mine visibility to facilitate better machinery maintenance and operation (Source: Mining Technology).

Data was formerly painstakingly gathered and written down on paper. Large datasets couldn't be gathered with this strategy, and the data's full potential couldn't be realized. With smart mining, IoT sensors and gadgets are used to automatically collect enormous amounts of correct data. In addition to being able to gather enormous volumes of data, machine learning and artificial intelligence (AI) can be used to perform computations and interpret the findings automatically. AI also uses data to forecast operational requirements and produce actionable items for process improvement.

Advantages of Smart Mining Implementation

Reduced Operational Costs

Although deploying smart mining technology has a high initial cost, over time they help lower mining operations expenses. Automating tasks that are typically performed by people increases productivity and boosts earnings. Also, a smaller task force is feasible because fewer humans need to be on the field at once when automated machines are performing diverse jobs. Additionally, automation eliminates expenses like labor for manual data collecting and cable maintenance. Equipment, energy, and safety are a mine's three key cost components. Equipment purchases result in lower energy and safety expenditures. Smart sensor data collection makes mining more energy-efficient, reduces the cost of costly safety occurrences, and creates a safer working environment.

Optimized Decision-Making and Workflow

Every step of the mining process, including mine discovery, excavation, stockpile management, and sales, may be more easily optimized thanks to big data automation. Because errors or inconsistencies are discovered and fixed more quickly as a result of large-scale data collection, there is less downtime. Also, it makes tracking supplies across the value chain simpler, saving time that would otherwise be spent on logistics. Organizations can continuously adapt and uncover areas for development by regularly reviewing data, resulting in a lean and efficient organization. Smart technology can automatically offer insightful information that improves decision-making and frees up time to put positive changes into action. A mine may strengthen collaboration at all levels, which improves decision-making, thanks to interconnected device networks.

Precision in Drill and Blast Mining

Profits in mining are based on the quantity of natural resources extracted. Hence, achieving performance objectives requires ensuring that machinery is operated as efficiently as feasible. Utilizing AI and data analytics reduces the amount of time spent manually looking for ores and lowers the likelihood of human error. By utilizing smart technologies, the same mining location becomes more profitable and productive. The mining industry uses high-tech tools that make it simpler to comprehend the topography and weak points of a mine. Workers can better comprehend the topography of a mine thanks to technologies like drone mapping and picture recognition. (More about automated drones and image recognition software in this post.) The accuracy of explosive placement is improved by more precise mapping, which also maximizes other resources like the required number of explosives and hours of labor.

Advantages of Smart Mining Implementation

Equipment Predictive Maintenance

IoT sensors continuously produce data on the "wear and tear" of equipment, enabling equipment predictive maintenance. A mining operation can use predictive maintenance to predict when and where equipment problems will occur based on a variety of factors, including as usage, temperature, and pressure. As opposed to ongoing routine maintenance upkeep, this means maintenance inspections and replacements can be made only when they are actually necessary, saving money and resources.

improved hiring and retention of employees

In the mining sector, maintaining a trained staff is a constant struggle. A shortage of workers in the mining industry has been brought on by rising resource demand, ageing labour pools, and a lack of focus on skilled occupations among younger generations (Source: Mining.com). During the course of the next ten years, 60,000 employees will retire, making up about half of the existing workforce. To meet sector labour supply requirements, one source predicts that in the next ten years, 100,000 more workers will be needed (Source: Mines Canada). Although mining has always been a respectable industry for diligent people, it is becoming less and less popular as a career choice. A number of factors, including the emotional and physical toll, potential risks, and the isolation of many mining villages, contribute to this lack of interest. By enabling the use of cutting-edge technology and allowing for the possibility of working from a secure distance, smart mining increases the mining industry's appeal to potential new hires. Smart mining is giving more jobs to people with a wider range of educational backgrounds because to this new technology. Engineers, computer scientists, programmers, and data analysts make up the modern mining workforce (Source: Mines Canada).

Improved Worker Safety through Smart Mining

The benefits of Smart Mining for worker safety may be the most obvious benefit. Workers in the mining industry are exposed to physical risks such cave-ins, explosions, and severe temperatures. Mine employees are at danger for a wide range of illnesses, including respiratory conditions like lung cancer and "black lung disease" as well as physical injuries brought on by heavy lifting. Moreover, exposure to loud, repetitive noises carries the risk of hearing loss. Connective technologies, along with the necessary training and equipment, can help mining in producing thorough, actionable reports with the use of AI makes safety accountability, planning, training, monitoring, and upgrades easier. Negative behavioral trends can be immediately identified with the use of AI and machine learning, which analyses data constantly. Corrective training recommendations can then be made automatically (Source: Deloitte).

Many employees can operate remotely, away from the risks of unstable mine sites, thanks to smart mining and automated machinery. Hence, new technology have frequently eliminated a lot of labor-intensive jobs and increased general safety (Source: Ontario.ca). For instance, autonomous vehicles transfer items to the appropriate locations while keeping people out of hazardous regions. Technology also keeps employees safe who cannot perform their tasks remotely. Smart PPE and wearable sensors can notify employees about anomalies in their environment or their own biometrics, pushing them to follow emergency measures when necessary, in situations where miners must work in potentially hazardous settings.

Environmental incident prevention

Any mistakes in the mining sector have the potential to cause serious environmental damage, injury, and even death. Using cutting-edge technology to automate machinery, keep an eye on operations, and use data to predict results and make effective decisions is the ideal approach.Jiskani et al. developed a framework based on six leading indicators that evaluate mines for cleaner production in their paper "Green and climate-smart mining: A framework to analyze open-pit mines for cleaner mineral production." The indicators are environmental protection, pollution control, waste management, energy and resource consumption, technology enablement and implementation, and strategic and managerial efficiency. IIoT can assist mines in enhancing each of these areas of performance.

The Obed Mountain coal mine spill is one environmental issue that may have been discovered and reduced with network technology. This spill happened in Alberta in 2013 as a result of a tailings dam breaking. The outcome? A billion liters of sewage were released into the nearby river (Source: The Globe and Mail). The ecology was severely damaged by this catastrophe, and the water was temporarily unfit for drinking and irrigating crops. The tailings dam's lack of structural integrity may have been identified earlier with the correct technologies, averting the contamination of Alberta's water supply.

The large-scale collection of real-time data is the greatest method for operations to prevent unforeseen environmental effects. AI technology may utilize algorithms to identify environmental problems and produce useful insights from previous data. Moreover, AI may be used to forecast energy peaks, enabling businesses to better manage their energy use, lower total energy demand, cut expenses, and lower greenhouse gas emissions.

Technologies Used in Smart Mining

Underground Monitoring Systems

Workers may stay continually informed about the state of the subsurface environment and mining activities thanks to an underground network of IoT-powered sensors. These sensors share data among various devices by connecting to the Internet and one another. Because IoT devices capture a lot of data and make it easier for operations to collaborate, businesses that employ IoT typically decide to store their data on the cloud. Sensors allow for the massive data collection that makes smart mining so much more effective than conventional mining techniques. With more information, mining activities may be better understood, allowing for improved planning and overall site improvements. Moreover, IoT sensors enable a mine to detect anomalies as soon as they occur rather than waiting until problems have worsened. Both above- and below-ground miners can receive real-time updates on problems and respond to them more quickly.

Autonomous Smart Mining Vehicles

Although we wait for self-driving cars to appear on our highways, automated fleet vehicles are already having an influence on the mining industry, which has been anticipated for decades. These vehicles do route tracking, load and unload cargo, environment positioning, and autonomous parking (Source: CNBC). Route tracking is the process by which machines employ AI to determine the best path to take. Autonomous vehicles save gasoline by determining the best potential route. Because of built-in collision awareness and communication with the rest of the fleet, efficiency is increased and the number of accidents is decreased. Mining equipment frequently enters dangerous locations, endangering the lives of the drivers. Automated transportation keeps passengers safe and lowers the likelihood of accidents.

Remote-controlled Drills

Drills that are controlled remotely are controlled from a console that is situated far away. This indicates that employees aren't at risk for the regular drilling risks. Moreover, operators can utilize numerous drills at once, which boosts productivity. Moreover, autonomous drills allow for more exact drilling. Material that has been unevenly blasted is more difficult to handle and requires more expensive processes. Drilling is more accurate with modern technologies, providing a superior base for the entire process.

Technologies Used in Smart Mining

Unmanned Aerial Vehicles (UAV)

Drones, or unmanned aerial vehicles, are used to visualize geographic regions and prospect for new minerals. Drone imagery offers a precise, in-depth perspective of the terrain that is not feasible without technology, saving time and money over sending a team of humans to stake out the area and having to construct roads for them. Much faster than in-person mapping is drone mapping. Moreover, it allows for mapping hitherto inaccessible places with a 1 cm level of precision (Source: Wingtra). Automated drones survey dangerous regions in addition to mapping mines to ensure worker safety. They are also used by employees to measure, control, and conduct inspections.

3D Laser Scanning in Smart Mining

In the mining business, three-dimensional laser scanning is a relatively recent technology. It has long been utilized in civil engineering and architecture. This method makes a 3D map of the area by studying the geography using laser light. Workers can better plan drill holes, conduct mine exploration, and manage projects by analyzing the resulting geographic data (Source: Mining Technology).

Geographic Information Systems (GIS)

GIS gives mine workers a more thorough understanding of a region's geography, especially when the terrain is difficult to reach. With the help of this technology, you may see a mine in three dimensions along with its position and other geographic elements' size and shape. GIS creates a digital map by superimposing different "layers" over a base map. Depending on your needs, you can switch between different maps that display additional landscape characteristics. Workers can then access a database of geographic data and examine comprehensive maps on a variety of devices from a variety of places using GIS apps.

Image Recognition Technology

For the purpose of identifying ores and distinguishing them from their surroundings, smart miners employ image recognition technology. The mining process is streamlined and human error is reduced because to the improved accuracy.For instance, image recognition can distinguish between different grades of copper, some of which are appropriate for various marketing purposes.

Technologies Used in Smart Mining

Smart PPE (Personal Protective Equipment)

There are "Smart" versions of many PPE items, including hardhats, vests, safety goggles, and boots. The various sensors and communication tools that connect workers, especially lone workers, and provide them access to real-time biometric data to protect their safety in hazardous locations, may be found in these safety wear items. Mine employees and managers can be alerted to an event as soon as it occurs and can send out emergency assistance more quickly by analyzing physiological signs like body temperature, respiration frequency, and heart rate. For instance, if a person fell, their heart rate would significantly increase. Some intelligent protective equipment (PPE) can even identify dangerous compounds and gases, saving fatal injury. (Refer to Oilman). Mineworkers adhere to rigid work/rest schedules to keep safe in a hazardous workplace. Monitoring biometrics through PPE keeps everyone aware of each worker's condition so they can take breaks as needed and avoid overexertion.

.png)

Technology Trends in Mining

Since the beginning of industrial mining, technology has played a growing role in the industry. Dynamite, the industrial revolution, and electric conveyor belts all made it simpler to load and move materials. Dynamite also helped clear tunnels and reach deeper depths than was possible with a pick and hammer. The most recent significant technological advancement for the mining industry comes from digitization, which is taking place as the fourth industrial revolution takes hold. The Internet of Things (IoT), wearable technology, drones, automated machinery, enhanced data analytics, artificial intelligence (AI), 3D modelling techniques, and increasing connectivity are all major forces behind this digital revolution. In order to reduce operational and legal risks, there is a rising push to optimize equipment and systems and to take a proactive, rather than a reactive, approach to regulatory compliance, safety, and environmental concerns. Also, there is a strong emphasis on using technology wisely to increase competitiveness and operational efficiencies.

Mining may have adopted digitalization a little later than other industries, but it is already catching up. According to a report1, the global market for smart mining was valued at USD 6.8 billion in 2019 and is projected to grow to USD 20.31 billion by 2025. Notwithstanding the COVID-19 pandemic, this tendency will continue, and in many respects, it will highlight how important it is for the industry to keep automating and digitizing rather than relying on manual processes.

Prospecting and exploration

Drones, AI, and 3D modelling are being used in prospecting and exploration. Prior to the development of new mines, 3D modelling techniques use software to create blueprints for underground areas. By enabling the photography of locations that would otherwise be challenging or impossible to access, this can increase the geographic scope of exploration activity. By providing users with more knowledge about a mine's safety and by minimizing the need for humans to explore potentially hazardous or unexplored subsurface areas, modelling also presents substantial opportunities for worker safety. By assisting mining businesses with the organization, comprehension, and decision-making of the enormous volumes of data they acquire, AI offers significant advantages. At the prospecting and exploration stage, accuracy is essential because excavating in the wrong place can be a very expensive mistake. Companies can accurately find deposits with the use of AI. By raising their strike rate, businesses can lower the upfront expenses of their investments, which should boost profits.

Technology Trends in Mining

Recent years have seen a remarkable advancement in drone technology. Drone use has the potential to significantly lower labour costs and improve data collection. For instance, a single drone can currently perform the same aerial surveying tasks as a team of helicopters. An improved drone's AI system enables it to comprehend the environment and terrain it is aerially scanning better, which helps businesses decide where investigation should be focused.

Development and production

Production and development are both being significantly impacted by digital technology. For instance, automation technology and advances in AI can significantly increase operational and financial efficiency, especially when used in conjunction with autonomous cars, drillers, and haulage systems. Without a human driver, self-driving trucks can travel through small tunnels. Compared to a human workforce, autonomous haulage systems (AHS) can securely handle and transport a lot more materials, increasing both productivity and safety. The first automated heavy-haul rail network capable of transporting roughly 1 million tonnes of iron ore per day was unveiled in 2019 by a major mining corporation. Additionally, firms utilizing AHS technology have experienced productivity benefits of over 20% since installing, according to several heavy equipment manufacturers. In a sector where labor costs are considerable, automation brings about apparent advantages at an operational, production, and staffing level. The health and safety of mining operations is also improved by removing personnel from hazardous working environments. Moreover, AI is being used to enhance operational effectiveness, safety, and production process, such as by more accurately forecasting mineral distributions to improve mining efficiency.

There are several situations where connected and intelligent gadgets are being used. Real-time data from intelligent sensors, such as those affixed to mining systems and equipment, can, for instance, help optimize equipment performance and enable preventative maintenance before equipment fails, saving time and money and lowering the risk to health and safety. In the same way that the IoT is making our homes "smart," new mines are being built with the IoT in mind, and one of the first intelligent mines in the world is about to begin production. This mine will put in place systems that link every part of the mining value chain, allowing the mining operator to evaluate massive amounts of data in real time and come to the best decisions for its operations and production. Wearables are being utilized in addition to automation and AI to check workers' fitness for work, offer real-time data on their locations, and monitor health and safety issues. Mining businesses employ digital twins, virtual and simulated reality, and sophisticated simulations to operate more accurate mine operations, improve equipment and operation monitoring, and execute advanced simulations. Employees can receive immersive training using VR/AR (virtual reality/ augmented reality), enabling them to get ready for challenging situations in a secure setting. Also, it has enormous potential for incident investigations and forensics.

Intellectual Property & Green Mining

A demand in every aspect of our life, switching to greener technology has emerged as the globe struggles with the growing climate problem. Naturally, sectors that are essential to our daily existence are also implementing such technologies. The mining industry, which obtains and refines the raw materials necessary to create the majority of green technology, is a factor in all of these. However there is still a serious need for greater research into the economic and policy elements that encourage the mining industry to become more sustainable.

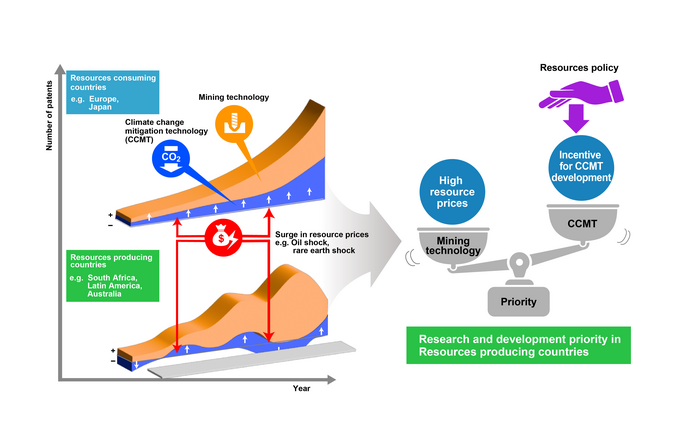

Strategies for supporting R&D in mining-related climate change mitigation technology, or CCMT, can be found by analyzing trends in global patent filings from the mining and minerals sector. The Paris Agreement and changes in raw metal prices have an impact on the industry's development of CCMTs, although the impact differs by country and how much the sector contributes to that nation's economy.

Reducing greenhouse gas emissions and our environmental impact is the aim of CCMT development. Examining patent applications over time is a useful method for determining how a certain industry's technology is evolving. It offers interesting insights to examine patent data from 2001 to 2016 from seven regions to calculate the three key indicators of CCMT development in the industry for each region: Priority, Mining, and Scale. The 'Priority' indicator is the ratio of the number of mining-CCMT-related patents to the total number of mining industry patents. If inventors prioritized research into CCMTs, that percentage would rise. The quantity of mining-related patents split by the overall quantity of patents is referred to as "mining." This figure reveals how heavily inventors are focusing on creating technology for the mining sector as a whole. The entire number of patents, which represents the whole quantity of research and development, is the definition of "Scale" at the end.

Using these metrics, the mining industry in seven important nations and areas will be examined, including China, Japan, the United States, Europe, Latin America, Australia, and South Africa. The first four, which are significant patent offices, and the last three, which are significant mining districts, offer insightful information on changing trends.

Intellectual Property & Green Mining

Both overall mining patents and mining CCMT patents increased, but the rate and pattern of those trends vary depending on whether a country is a resource producer or a consumer. In reaction to increases in the price of commodities like rare earth metals and oil, resource-producing regions changed their priorities for research and development more significantly. A relative rise in mining-related R&D has aided in the development of mining CCMT patents in the US, Europe, Latin America, and Australia. While reducing the entire scope of their R&D, Japan and South Africa have expanded their concentration on R&D for both mining itself and associated CCMTs. Nonetheless, China and the rest of the globe have expanded their R&D efforts, which has led to the development of more green technologies.

The growth in mining patents (orange) and CCMT patents (blue) was not uniformly distributed among resource-producing and resource-consuming regions. In actuality, it was based on developments in the world economy that affect how much it costs to mine minerals. Whether a region produces or consumes resources determines the degree and kind of variation. Countries can create policies that support the development of CCMT in the mining sector by becoming aware of these developments.

CREDIT - Kyushu University/Fujii Lab/Science Graphics

By promoting the development of CCMTs for the industry and maximizing the benefits for all, these types of analysis can assist both nations and companies in implementing effective policies. The distinctions and similarities between R&D approaches can be utilized as a springboard for developing nation-specific science and technology policies that might address the climate catastrophe.

Over the past ten years, mining innovation has exploded. The highest proportion of global innovation, as assessed by mining R&D expenditures, exploration expenditures, or mining technology in patent data, is concentrated in Australia, Canada, China, Europe, and the United States.

The value chain and lifecycle of mining production are accelerated through mining innovation. Recent mining innovation, in particular, concentrated on technologies for exploration and refinement. However compared to other subsectors, some have made a bigger contribution to the recent increase in mining innovation. Particularly, there has been a shift in market share away from technology used for refining and towards those used for exploration and transportation. We interpret these findings as being a direct effect of the spike in demand for mineral goods during the same time period.

IP Focus Areas within Mining

Minerals processing technologies

Sensors and process monitoring

Minerals processing methods

Heavy mining equipment and machinery

Mining and extraction methods

Tailings treatment and disposal technologies

Tailings treatment methods

Please feel free to reach out to one of our subject matter experts at info@effectualservices.com

to explore, how we can help you & make the world a better place to live in !!!

Effectual’s SMART MINING TECHNOLOGY RESEARCH FRAMEWORK is a deep dive into this ecosystem and shall help you understand the intricacies of this nascent innovative domain with insights backed with credible data sources. Some ways we can help include, but not limited to - Performing any previous art or freedom to operate searches to help you better grasp the environment surrounding your invention or business endeavors. If certain methods of IP protection are more appropriate for your technological or business goals, we can help you strategize effectively to plan for future & in making continuous innovation a part of your working model.

Solutions Driving Innovation & Intelligence

Enabling Fortune 500's, R&D Giants, Law firms, Universities, Research institutes & SME's Around The Globe Gather Intelligence That

Protects and Nurtures Innovation Through a Team of 250+ Techno Legal Professionals.