Mineral Processing Technologies: Optimizing Blaine Surface Area Through Microwave-HPGR Integration

Particle Size Controlling Through Application of Microwave at the HPGR Feed

Technology summary

- The present study evaluated aspects of microwave application to the iron ore concentrate fed to HPGR in a bench scale unit. Iron ore concentrate was irradiated varying the microwave exposure time and grinding efficiency was evaluated.

- The moisture influence in the HPGR efficiency was also assessed. The pellet feed blaine surface area (BSA) improved by 300 cm2/g and % < 325# fraction by 3%. Scanning electron microscope (SEM) images show the formation of micro-cracks onto the particle surface induced by microwave; the effect observed helped improve the milling process performance, in addition to the moisture reduction observed due to the temperature increase.

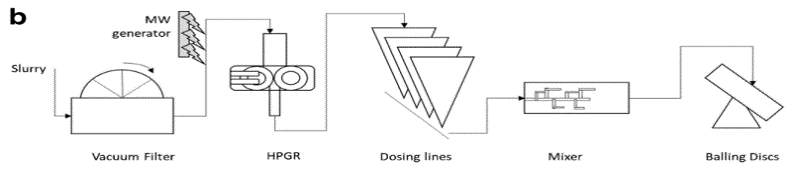

- The figure below shows the flowchart of a pelletizing process, including a Microwave (MW) Generator to support the HPGR process.

Advantages of mineral processing

- The microwave irradiation shows a 3.5 cm2 /g/s improvement on the BSA after grinding on the HPGR, which should be attributed to an increase in size fraction % < 10 μm from 25 to 34%.

- The pellet feed preparation for pelletizing may take advantage of a microwave pre-treatment prior to HPGR, because a higher BSA is desirable to improve the capillarity forces within the grains.

- The pellet feed has an excellent fast heat up. The sample reached 80 °C within 50 s, which may improve the balling and drying process and need to be study in future.

- The microwave effect on the particle size reduction was quantified as 40% for BSA increase and 22% for % < 325# fraction increase.

- The BSA and % < 325# fraction increase was related to the generation of micro-cracks onto the particles, observed on the SEM images which lower the needed milling energy to break the particle.

Mineral Processing Technology

Raw Material

Industrial itabirite concentrate obtained from an industrial pelletizing plant located at Anchieta (Brazil) was used in the experiments. Representative samples were generated by quartering and riffling sampling methods (ASTM E 877-03, 2003). Blaine specific surface area was measured according to ASTM standard (ASTM C 204-07, 2007). The chemical composition and physical properties are shown in Table 1.

Experimental Procedure

The concentrate was treated in a microwave oven, multimodal, provided with a turntable-tray model LG MH7048G (2.45 GHz, power of 1000 W). An additional exhaust system (1 L/min) is placed on the lateral side to standardize the steam withdrawal. The sample holder is a Teflon high-temperature resistant plate (Fig. 3) to keep the irradiation power density constant in the sample.

In every treatment, the iron ore was irradiated in 100 subsamples of 150 g, in order to keep the power density and electromagnetic field homogeneous on the whole sample. The treatments were conducted in time steps of 0, 10, 30, and 50 s, in duplicate. The sample temperature was gathered after every treatment and the average recorded for each time step. The average temperature on bulk surface was measured using a model Raytec ranger 3I infrared thermometer after switching off the microwave power. In order to access the heat efficiency, 100 ml of water (cp = 4.18 J/g/°C) was placed in the same sample position to evaluate the amount of heat absorbed regarding the power input setup. The result is a 68 ± 1% furnace efficiency (E) for absorption in relation to the nominal power input, the complement is dissipated as heat, mostly in the magnetron tube. Figure 4 illustrates the position of an industrial application in the flowchart; the irradiation time can be translated into the distance over a conveyor belt, before feeding the HPGR.

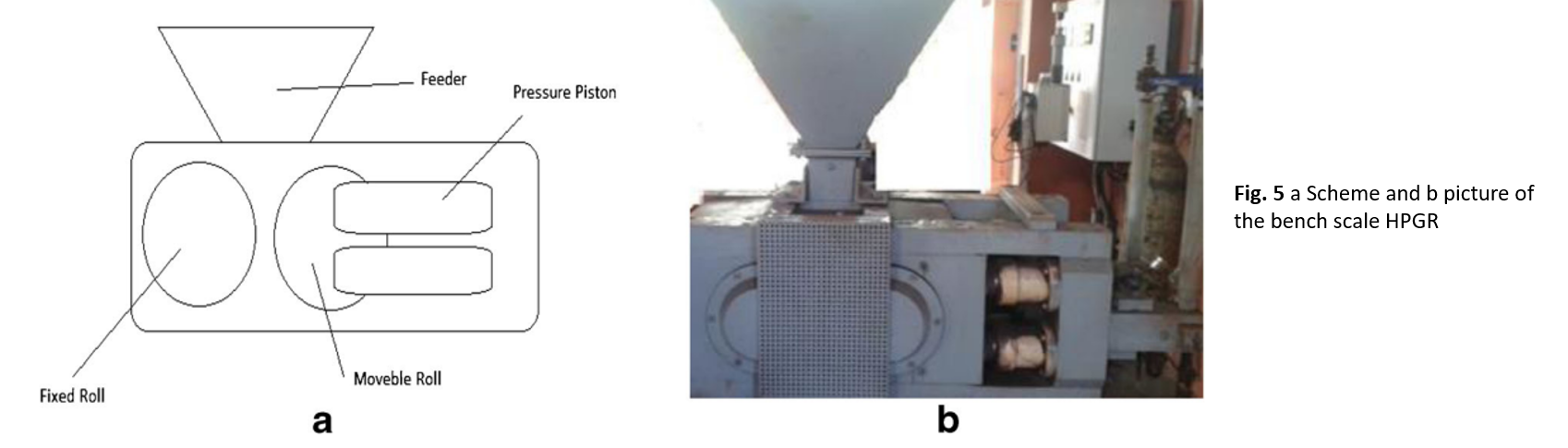

Milling Experiments at the HPGR

A bench scale Polysius LABWAL HPGR (250-mm diameter and 100-mm length), shown in Fig. 5, processed the concentrate irradiated. Every test used a 15-kg sample (feed rate of 30 kg/h). Alves [23] determined that good-quality results could be obtained from samples of only 5 kg, where a typical standard is in the range of 25–30 kg. Comminution was achieved by compressing the particle bed using two rotating rolls, where one is forced against the other by a hydropneumatics piston system. The setup oil pressure was 50 N/mm2 , roller speed kept constant at 0.3 m/s (zero gap 2.91 mm).

The milling experiment was conducted by two feeding methods:

- BOriginal^: A part of the representative samples generated by quartering and riffling sampling methods, reposed at room temperature for 2 h.

- BTreated and pressed only^: 100 concentrate subsamples obtained from the microwave treatment were homogenized and reposed at room temperature for 2 h.

- Treated and pressed remoist.^: 100 concentrate subsamples, after the previous procedure had the moisture adjusted to reach the initial 10% w/w and then homogenized again. The procedure intends to evaluate the influence of the microwave, without considering the moisture released during the heating.

Test Methods and Results for the Advantages of Mineral Processing Technology

Test Methods: Particle Size Analysis

The particle size distribution was performed with a Mastersizer 2000E, capable of analyzing particles between 0.02–1000 μm. Parameters were fixed at a pump speed of 3000 rpm, the measurement time of 6.5 min and pulp concentration of 0.01%w/w . The sample was prepared in distilled water.

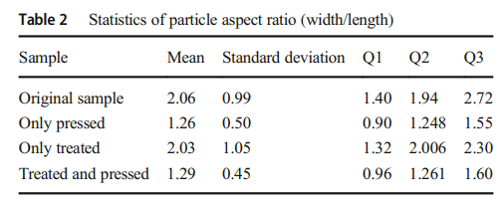

The particle aspect ratio shown in Table 2 corroborates with the observed distinct breakage behaviors of the particles. Some particles became more brittle by the introduction of the micro-cracks. In general, breakage is a strong function of the specific energy level in the HPGR, as observed by Abiyzeid et al. [27], but the micro-cracked particle is not significantly affected, it is explained by the lower energy needed to break. This effect on the size is dependent on differences in brittleness of feed components. The cracked particle (soften) tends to generate ultra-fines, whereas the other stronger particles break down into large parts, only reducing aspect ratio.

Result and conclusion

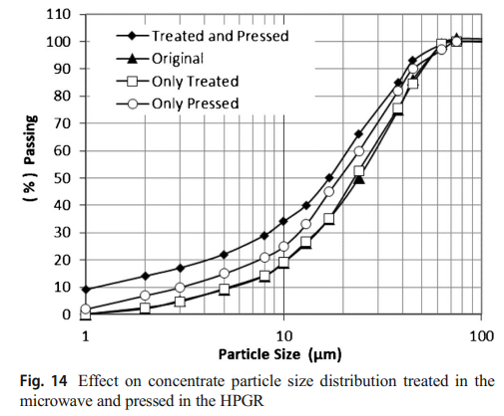

The PSD curves (Fig. 14) show that samples treated with microwave and then ground by HPGR present more fine particles than the sample only ground in the HPGR, at the same size fraction. Therefore, pellet feed preparation for pelletizing may take advantage of a microwave pre-treatment prior to HPGR, because a higher BSA is desirable to improve the capillarity forces within the grains. The pre-treatment increased from 25 to 34% the fraction % < 10 μm (responsible for 11.1% increase in the BSA), while the fraction % < 325# fraction slightly improved by 3%.

Test Methods: Specific Surface Area

The measurement of the air permeability of a bed of fine particles was measured in the instrument based on the ASTM C-204 (2011), to obtain the BSA.

Result and conclusion

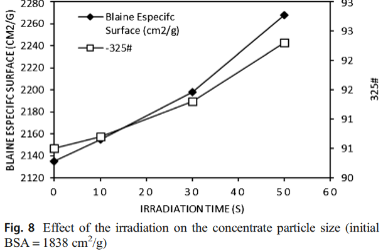

The grinding efficiency at bench scale HPGR was assessed based on the evolution of the iron ore concentrate BSA and % < 325# fraction. As shown in Fig. 8, microwave irradiation induces a significant increase in BSA and % < 325# fraction. The same was applied to the load and feed rate at the HPGR, but increasing the microwave irradiation will lead likely to an increase on the comminution of the particles (increasing the portion of ultra-fine, represented by a higher BSA). The BSA increased at a rate of 3.5 ± 0.3 cm2 /g/s of irradiation. At same time, the rapid increase in BSA was followed by a % < 325# fraction increase, which is also essential to better balling efficiency [11].

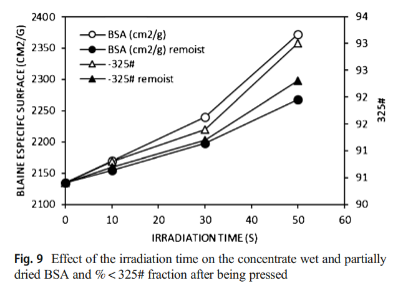

The microwave effect on the HPGR efficiency was evaluated. In order to evaluate the effect alone, the HPGR improvement expected due to the lower moisture after microwave heating was isolated. Figure 9 shows the particle size results of the Bpressed and treated remoist^ sample and the Btreated and pressed only.^

The samples Btreated and pressed only^ had an increase of BSA and % < 325# fraction after grinding of 534 cm2 /g and 4% respectively, but the moisture content of the sample heated was 4% less than the initial sample (Fig. 7)

The variation of BSA and % < 325# fraction shown in Fig. 9 with microwave irradiation can be split between a microwave effect and moisture reduction.

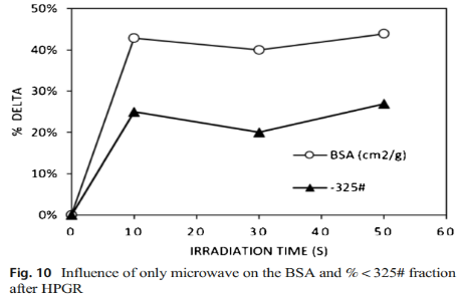

In Fig. 10, the total variation was considered when moisture was not added to the concentrate (moisture reduction + microwave effect), but partial variation (%Delta) can be also calculated, as in Eqs. (4) and (5). The microwave effect contributed with 42 ± 1% of the BSA increase and 24 ± 2% of the % < 325# fraction increase; the complement to the total variation are due to the moisture reduction effect. In summary, the microwave influence is more than twice more relevant for the BSA than to the % < 325# fraction. The microwave irradiation affects the generation of the very fine particle, which has greater surface area per unit of mass (bellow 10 μm). Consequently, the moisture reduction had a stronger influence on the increase of % < 325# fraction than BSA.

Test Methods: Particle Aspect Ratio by SEM Using Image Analysis

The samples were analyzed using a scanning electron microscope (SEM) JEOL–JSM 35C Model. The sample was coated with a thin layer of carbon in order to get the sample sufficiently conductive. The images were taken at × 500 in different sample zones mapping randomly the particles. Image J software was employed to provide the aspect ratio. The aspect ratio is always either equal or greater than 1.0 (ratio length/ width). A symmetrical particle shape in all directions, such as a sphere, has an aspect ratio of one, while an elongated particle has a higher than one aspect ratio. The images were analyzed after calibration for dimensions, contrast improvement, and background noise minimization, a threshold to extract particle from the background through a binary image.

Result and conclusion

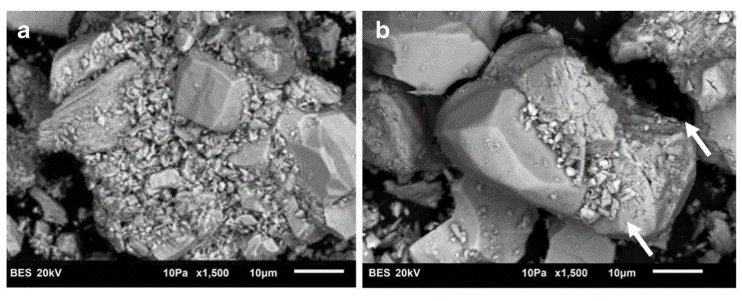

Figure 11 shows SEM images conducted on the original sample and after 30 s of irradiation. Particles before grinding but just irradiated show already some degradation, with fine micro-cracks all over the surface of the particles.

Several microcracks observed in the minerals in Fig. 11b occurred because different minerals respond to the electric field in different ways, which leads to different heating rates [19]. No internal pressure release can be attributed to the fact as the crystallized moisture are the same from the initial value after irradiation, which is expected seeing that low temperature was achieved.

Figure 12 shows an example of a martite particle with micro-cracks rooted in several directions, which lower the needed milling energy to break the particle. The particle shape of the sample after the HPGR was also analyzed by SEM.

The HPGR increases the proportion of ultra-fines in the sample, shown in Fig. 13.

Additionally, Fig. 13 shows in BTreated and Pressed^ sample that an additional increase of ultra-fines covers the main particles, which support the observed increase of BSA in this sample. On the particles of BOnly Treated^ sample, the microwave absorber minerals hematite, goethite, and martite show branched micro-cracks not following any specific direction, characteristic of the microwave effect into the minerals.

Ultrasonic Crushing Device for Reinforcing Complex Ore Separation

Problem

One significant challenge with existing comminution technology is that there is typically poor control over particle size distribution, leading to an excessively broad-spectrum of particle sizes in the final comminution product.

Traditional size reduction methods remain energy-intensive, and despite technological progress, certain approaches may still demand substantial power inputs.

Solution

The microwave irradiation shows a 3.5 cm2 /g/s improvement on the BSA after grinding on the HPGR, which should be attributed to an increase in size fraction % < 10 μm from 25 to 34%.

The PSD curves (Fig. 14) show that samples treated with microwave and then ground by HPGR present more fine particles than the sample only ground in the HPGR, at the same size fraction.

Figure 12 shows an example of a martite particle with micro-cracks rooted in several directions, which lower the needed milling energy to break the particle.

Application & Advantages

The pellet feed preparation for pelletizing may take advantage of microwave pre-treatment before HPGR. The pellet feed blaine surface area (BSA) improved by 300 cm2/g and % < 325# fraction by 3%.

The formation of micro-cracks on the particle surface induced by microwaves lowers the required milling energy to break the particle.

Also, the microwave treatment enhances the milling process performance and produces more fine particles within the same size fraction.

Metso Outotec Grinding Optimizer

Technology Summary

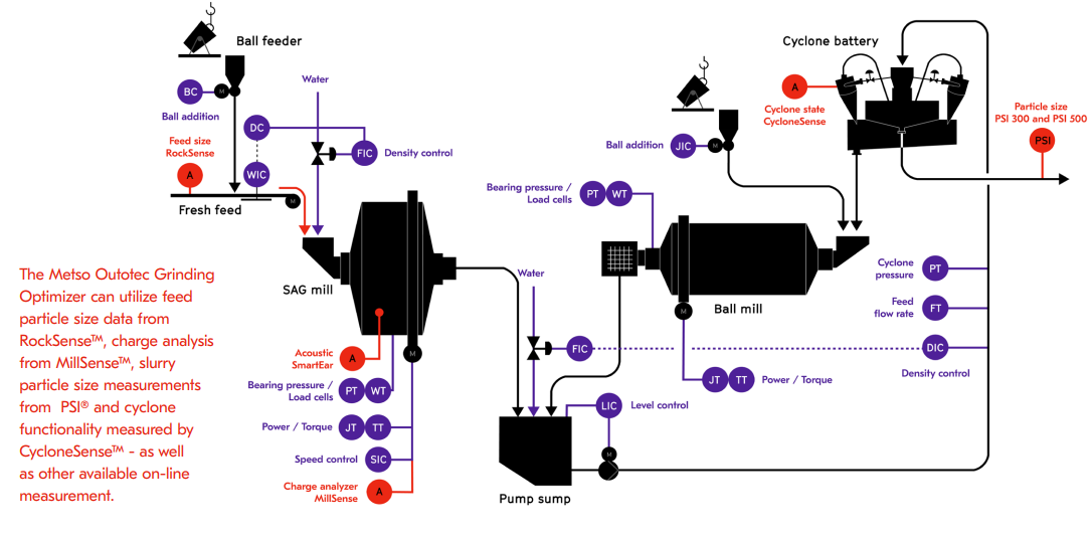

Metso Outotec Grinding Optimizer – with the RockSense™ on-belt rock size analyzer, MillSense™ charge analyzer, PSI® particle size analyzer and CycloneSense™ hydrocyclone performance monitor – gives you a complete solution for controlling and optimizing your entire grinding circuit.

The Grinding Optimizer overcomes these limitations, and combines our grinding experience with a multivariable, model-based controller. Controlled variables typically include final particle size after grinding, primary mill charge level, power and weight and other customer specific targets. To achieve the targets, Grinding Optimizer manipulates the setpoints of multiple regulatory controllers in the grinding circuit, such as mill feed rates, rotational speed, water additions, cyclone feed characteristics, etc.

Advantages of mineral processing

The system has the following advantages

- Stabilizes the process,

- Maximizes throughput,

- Improves control of particle size, and provides accurate on-line analyses of the most critical variables,

- It also improves utilization of grinding capacity,

- Maximizes process throughput,

- Optimize the water usage,

- Reduces energy consumption, and

- Enhances overall equipment efficiency.

PSI® Particle Size Analyzers

PSI 300 On-line slurry particle size analyzer Particle size monitoring and control increases average throughput and reduces particle size variability in grinding products.

This improves the downstream process by minimizing reagent consumption, maximizing recoveries and improving de-watering efficiency. The PSI 300 Particle Size Analyzer is an on-line analyzer system for mineral slurries.

It automatically takes samples from one to three process streams and measures P40 to P90 particle size in the range of µm (500 to 15 mesh). Density and ph of the sample can be measured as an option.

Working Mechanisms of Device

ROCKSENSE™ SYSTEM & MILLSENSE™ SYSTEM

ROCKSENSE™ SYSTEM

The RockSense system is an on-line particle size analyzer system for ores moving on a conveyor belt. The system uses high-performance 3D laser imaging technology that is resistant to changes in external lighting conditions.

RockSense analyzes the rock particles during normal belt movement without affecting the capacity of the conveyor belt. The excellent resolution and realistic scale of the images is achieved by combining a high resolution 3D laser scanner with a rotary encoder. RockSense provides the following analyses: Particle size distribution with user-definable statistical measures; Cumulative volume flow estimation.

MILLSENSE™ SYSTEM

The MillSense system provides on-line analysis of the mill charge position and volume by directly measuring the charge’s toe and shoulder angles. The volumetric charge measurement has proven to be an invaluable input for mill optimization and for decreasing disturbances caused by ore changes. The MillSense sensor is directly attached to a liner bolt and uses wireless technology for both power and data transfer.

The benefits of MillSense include: Higher mill availability; Fewer unexpected shutdowns; Improved mill throughput from running the mill at the optimal charge volume; Protection of liners; Improved robustness for ore hardness changes.

PSI® PARTICLE SIZE ANALYZERS

The PSI particle size analyzer is a market-leading on-line sizing system for mineral slurries. Particle size monitoring and control improve throughput and help to maintain the target grind in the grinding circuit. Additionally, it improves the downstream process by minimizing reagent consumption, increasing recoveries, and making thickening and filtration more effective.

Metso offers two particle size analyzers. PSI 300i is the preferred instrument for most grinding control applications to measure P40 to P90 particle sizes ranging from 25 to 1,000 μm. PSI 500i is recommended for applications with particle sizes ranging from 0.5 to 1,000 μm.

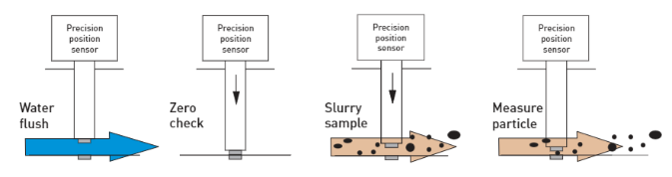

Primary sampling

A representative stable primary sample flow is essential for dependable particle size measurement's 300 can handle one to three sample inlets, each with a recommended 70–170 l/min flow. The ideal location for PSI 300 is just below the primary sampler for the shortest distance sample gravity fl ow. The PSI 300 has integrated, automatic controls for the primary samplers, with optional remote controlled water and slurry valves and sample cutter cleaner. When utilized, these options guarantee high sample availability.

Secondary sampling

Primary samples are directed to a reject outlet when they are not measured. A moving hose sampler after each primary sample inlet cuts a secondary sample for the actual particle size measurement from one sample line at a time. A self-cleaning trash screenland a small level controlled tank are used to remove trash, oversized particles and air bubbles from the sample. The primary sample flow is reduced to a stable 10–20 l/min flow, which is fed internally to the PSI 300 sensors by gravity. An automatic water spray – flush – dump valve system kills froth, prevents sanding and reduces scaling to a minimum. The secondary sampler moving hose passes across a static cutter at programmed intervals to provide calibration samples or composite samples at the original (process) solids content for laboratory analysis.

Sensor head

The PSI 300 sensor head is based on direct size measurement of a representative sample of particles. The precision size caliper measurement data is converted to size fraction readings for each measured stream. Each of these corresponds to a user definable particle size screen fraction, such as percent passing 74 microns. This information is displayed on the analyzer's touch screen and can be sent to the plant process control system by several alternative communications protocols

Primary measurement results are calibrated against a reference method (sieve, for example). Calibration is robust, since the direct size measurement principle is not sensitive to changes in slurry viscosity, temperature and other properties. Periodic automatic zero check compensates for any drift and monitors the sensor operation

Sampling and analysis control

The analyzer has an electronics and pneumatics cabinet with an integrated industrial panel PC. It has a local touch screen user interface for displaying equipment status and analysis results in the field, and for invoking routine maintenance operations.

The PC hosts control and configuration software for the analyzer. A control application synchronizes the measurement with the sampling control sequence and provides an interface for measurement and diagnostic data transfer to the plant automation system. Analyzer results and status can also be seen through networked PCs, for example, in the control room.

Calibration

The PSI 300 is calibrated by measuring a series of samples and correlating the sensor signal readings with respective laboratory screen analyses. During the calibration procedure, sensor readings are saved and the measured sample is diverted by the calibration sampler into a sample bucket.

A quick calibration requires only a couple of samples. A range of approximately 20 samples is required to get the most accurate calibration equation. Due to the direct size measurement principle and automatic zero check, calibration stays stable over a long period of time.

Operating principle

The PSI® 300 analyzer actually measures a large number ofparticles from a representative sample. The analyzer uses a high-precision ceramic-tipped sensor to measure the size of randomly selected particles. The sensor sends the information to an integrated panel PC, which converts it to calibrated percent readings passing the selected mesh or micron sizes. The result is updated once per second based on the 120 measurements performed during the past 60 seconds. A zero check once per shift verifies operation and compensates for drift.

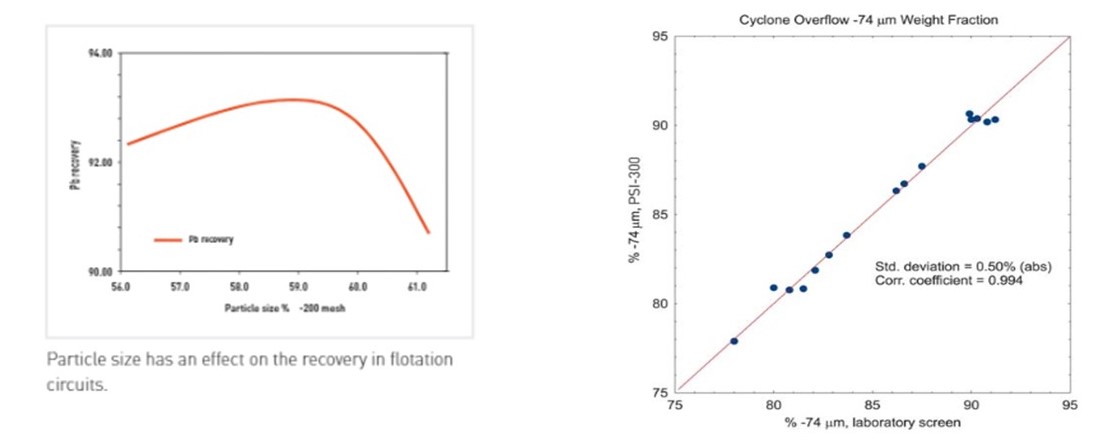

Test methods and results for the advantages of psi 300 analyzer

PSI® 300 readings

- Particle size has an effect on the recovery in flotation circuit.

- PSI® 300 readings are typically within 1–2% absolute error when compared with accurate laboratory screening results.

Metso Outotec Grinding Optimizer

Problem

In the conventional technology, obtaining high mineral dissociation and grinding efficiency under low energy consumption is a huge challenge faced by the mineral processing plant.

Traditionally, grinding circuits are operated manually or the controls are implemented as single-loop controllers. This approach does not take into account the multivariable nature of the grinding process, which easily lead to sub-optimal process performance.

Solution

The Metso Outotec Grinding Optimizer ensures stable conditions in the grinding circuit, provides optimal particle size for downstream processes, and aims for increased milling throughput while using less energy and optimizing water usage.

The Grinding Optimizer overcomes these limitations, and combines our grinding experience with a multivariable, model-based controller. Controlled variables typically include final particle size after grinding, primary mill charge level, power and weight and other customer specific targets.

Application & Advantages

Grinding Optimizer – with the RockSense on-belt rock size analyzer, MillSense charge analyzer, and PSI particle size analyzer – gives you a complete solution for optimizing your entire grinding circuit.

The system stabilizes the process, maximizes throughput, improves control of particle size, and reduces energy consumption.

The system available with PSI 300 On-line slurry particle size analyzer and control increases average throughput and reduces particle size variability in grinding products. It takes samples from one to three process streams and measures P40 to P90 particle size in the range of µm (500 to 15 mesh).

About Effectual Services

Effectual Services is an award-winning Intellectual Property (IP) management advisory & consulting firm offering IP intelligence to Fortune 500 companies, law firms, research institutes and universities, and venture capital firms/PE firms, globally.

Through research & intelligence we help our clients in taking critical business decisions backed with credible data sources, which in turn helps them achieve their organisational goals, foster innovation and achieve milestones within timelines while optimising costs.

Explore Related Resources

Mineral Processing Technologies: Objective & Market Trend

Mineral Processing Technologies: Ultrasonic Crushing Technology for Enhanced Ore Recovery

Solutions Driving Innovation & Intelligence

Enabling Fortune 500's, R&D Giants, Law firms, Universities, Research institutes & SME's Around The Globe Gather Intelligence That

Protects and Nurtures Innovation Through a Team of 250+ Techno Legal Professionals.