Mineral Processing Technologies: Ultrasonic Crushing Technology for Enhanced Ore Recovery

Ultrasonic crushing device for reinforcing complex ore separation

Technology summary

The invention belongs to the field of mineral processing and powder preparation, and specifically relates to an ultrasonic crushing device used to strengthen the separation of complex ores, increase the monomer dissociation degree of minerals, so as to reduce the energy consumption of subsequent grinding operations and improve the separation efficiency.

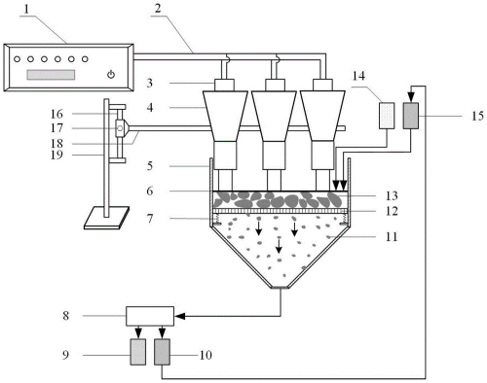

An ultrasonic crushing device used to enhance the separation of complex ores, including a crushing device and an ultrasonic generating device. The crushing device includes a crushing barrel 5 and a cover plate 6; the crushing barrel 5 is provided with a screen plate 12 and a spring 7. There is a cover plate 6 above the sieve plate 12, a spring 7 at the bottom of the sieve plate 12, and a support plate at the bottom of the spring; in the ultrasonic generating device, the ultrasonic generator 1 is connected to multiple ultrasonic transducers 3 through wires 2. The transducer 3 is connected to the horn 4, and the lower part of the horn 4 is connected to the cover 6 of the crushing barrel 5.

Advantages of mineral processing

- The high-frequency amplitude of ultrasonic waves is more likely to cause cracks at the grain boundary junctions. The cracks produced reduce the strength of the ore and will also help reduce the energy consumption of subsequent grinding. It is expected to effectively reduce energy consumption by 20%.

- This method uses physical methods to crush and has no pollution to the crushed products

- The device of the present invention can continuously crush and timely discharge the crushed materials, reduce the phenomenon of over-crushing of ore, and improve production efficiency

- The spring resonates with the ultrasonic wave at the same time, which helps the particles pass through the sieve holes more smoothly and prevents clogging.

- The ultrasonic crushing device selectively causes cracks in the grain boundaries of minerals and increases the degree of monomer dissociation in the crushed products, which is beneficial to subsequent grinding and sorting operations, saves corporate costs, and improves economic benefits.

Working mechanisms

The high-frequency amplitude of ultrasonic waves is more likely to cause cracks at the grain boundary junctions. At the same time, ultrasonic waves have a "cavitation effect". The cavitation effect in the cracks reaches an impact force far exceeding 1000 atmospheres, causing the cracks to further develop and ultimately achieve Selective dissociation between minerals greatly improves the degree of monomer dissociation of minerals in the ore, which is helpful for subsequent sorting efficiency.

Working mechanisms of device

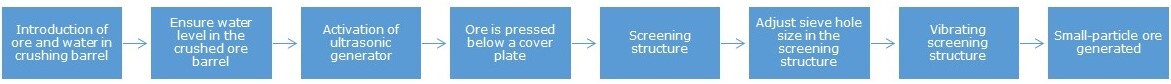

Specifically, the ultrasonic crushing device completed by the present invention proceeds according to the following steps:

- Open the valves between the feed bin and the water replenishing bin, the crushed ore barrel and the solid-liquid separator, so that the water level in the crushed ore barrel is 8-14cm higher than the cover plate;

- Turn on the water pump between the water replenishment tank and the return water bucket to keep the water level in a balanced state for recycling;

- Turn on the power and start the ultrasonic generator. The amplitude, speed ratio, frequency and other parameters of the ultrasonic generator can be adjusted according to the requirements for the particle size of the crushed product. One ultrasonic generator is connected to multiple transducers.

- There is a circular cover plate connected to the bottom of the transducer through a horn. The cover plate is packed with large particles of ore. There is a screening structure with a certain size of sieve holes under the ore. The bottom of the screening structure is equipped with springs symmetrically along the edge.

- The screening structure Welded together with the spring, there is a certain clamping strength between the spring and the cover plate, which can better fix large particles of ore. The vibration generated by the ultrasonic wave is transmitted to the screening structure through the packed large-grained ore, and the particles crushed below the screen hole size pass through the screen hole more smoothly, fall below the screening structure, and are collected in the cone of the crushing barrel. inside the cylinder.

- The cooling water added in the crushed ore barrel can not only improve the transmission efficiency of sound waves, but also improve the screening efficiency of ore particles. The water passes through the water replenishment bin, the crushed ore barrel, the solid-liquid separator, the return water barrel, and then to the replenishing water The warehouse forms a closed loop.

- The crushed ore passes through the solid-liquid separator and enters the crushed product bin.

- After each large-grained ore is crushed, first stop the power supply of the ultrasonic generator, and then turn off the circulating water.

In the above method, as the ore to be crushed under the cover plate is crushed and discharged from the screening structure, the ore on the screening structure decreases and the spring stretches, which makes it easier for the ultrasonic waves to directly act on the ore particles.

Test Methods and Results for the Advantages of Ultrasonic Crushing Device

Test Methods: Chemical multi-element analysis of raw ore

Use the ultrasonic crushing device to crush the spodumene, and feed 10kg ore with +10mm into the cover plate 6 in the crushing barrel 5 of the ultrasonic crushing device. The frequency of the ultrasonic generator 1 is 20kHz, and the power of the ultrasonic transducer 3 equipment It is 2kW, the amplitude of the ultrasonic wave is 80μm, the sieve hole of the sieve plate 12 is square, the side length of the sieve hole is 4mm, continue to work until there are no ore particles under the cover plate 6, disconnect the power supply and stop circulating water. The same weight of ore was used in a three-roller and four-barrel mill to obtain a standard grinding product, and the characteristics of the two grinding products were compared.

Results

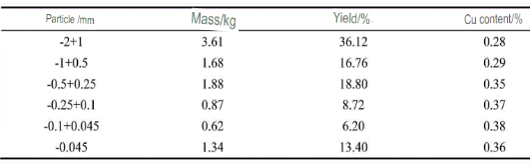

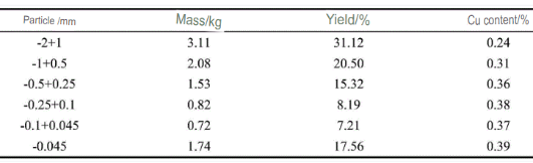

Table 2 Particle size distribution of standard three-roller four-barrel mill grinding products and Cu content in each particle size

Particle size distribution and Cu content in individual fractions for standard three-roll four-barrel mill grind products (Translation of image)

Table 3 Particle size distribution of products crushed by ultrasonic crushing device and Cu content in each particle size

Crushing of product particle size distribution and Cu content in each fraction by ultrasonic crushing apparatus (Translation of image)

Conclusion

From the comparison of the data in Table 2 and Table 3, it can be seen that the -0.045mm content in the products crushed by the ultrasonic crushing device is relatively high, increasing from 13.40% to 17.56%, and the Cu grade increases from 0.36% to 0.36%. This shows that compared with the standard three-roller and four-barrel mill, the ultrasonic crushing device can not only increase the content of fine particles, but also increase the content of valuable minerals and the degree of monomer dissociation.

Please note, it improves the degree of monomer dissociation of minerals in the ore, which is helpful for subsequent sorting efficiency.

Test Methods: Table 4 Chemical multi-element analysis of raw ore

Use the ultrasonic crushing device to crush the spodumene, and feed 10kg ore with +5mm into the cover plate 6 in the crushing barrel 5 of the ultrasonic crushing device. The frequency of the ultrasonic generator 1 is 20kHz, and the power of the ultrasonic transducer 3 equipment is 2kW, the amplitude of the ultrasonic wave is 80μm, the sieve hole of the sieve plate 12 is square, and the side length of the sieve hole is 2mm. Continue to work until there are no ore particles under the cover plate 6, disconnect the power supply, and stop circulating water.

The same weight of ore was used in a three-roller and four-barrel mill to obtain a standard grinding product, and the characteristics of the two grinding products were compared.

Results

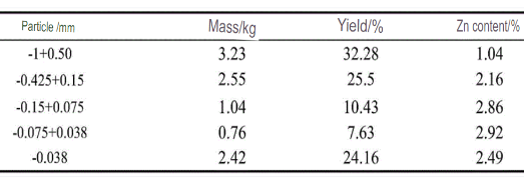

Table 5 Particle size distribution of three-roller four-barrel mill grinding products and Zn content in each particle size

Particle size distribution of three-roller four-barrel mill grinding products and Zn content in each particle size

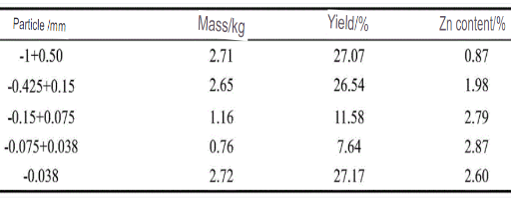

Table 6 shows the particle size distribution of the products crushed by the ultrasonic crushing device and the Zn content in each particle size

Shows the particle size distribution of the products crushed by the ultrasonic crushing device and the Zn content in each particle size

From the comparison of the data in Table 5 and Table 6, it can be seen that the -0.038mm content in the products crushed by the ultrasonic crushing device is relatively high, increasing from 24.16% to 27.17%, and the Zn grade increases from 2.49% to 2.6%.

Conclusion

This shows that compared with the standard three-roller and four-barrel mill, the ultrasonic crushing device can not only increase the content of fine particles, but also increase the content of valuable minerals and the degree of monomer dissociation.

Problem

The infrastructure and operating costs of crushing operations in the mineral processing plant are relatively high, generally between 50% and 50%. 60%. Therefore, obtaining high mineral dissociation and grinding efficiency under low energy consumption is a huge challenge faced by the mineral processing plant, which also affects the subsequent separation effect.

Solution

Ultrasonic wave has the strongest damage to the different minerals of the ores at the grain boundary junction, is favorable for the selective dissociation of the ores at the grain boundary, increases the monomer dissociation degree of the minerals, the energy consumption of crushing and grinding is reduced, and the subsequent separation efficiency is improved.

Application & Advantages

- The invention of an ultrasonic crushing device has the following advantages: reducing energy consumption, improving separation efficiency, enhancing production efficiency, saving corporate costs, improving economic benefits, and enhancing sorting and crushing efficiency.

- This method uses physical methods to crush and has no pollution to the crushed products.

- This shows that compared with the standard three-roller and four-barrel mill, the ultrasonic crushing device can not only increase the content of fine particles, but also increase the content of valuable minerals and the degree of monomer dissociation.

About Effectual Services

Effectual Services is an award-winning Intellectual Property (IP) management advisory & consulting firm offering IP intelligence to Fortune 500 companies, law firms, research institutes and universities, and venture capital firms/PE firms, globally.

Through research & intelligence we help our clients in taking critical business decisions backed with credible data sources, which in turn helps them achieve their organisational goals, foster innovation and achieve milestones within timelines while optimising costs.

Read Also: Hydrogen Use in Automobile Industry: Objective and Scope

Solutions Driving Innovation & Intelligence

Enabling Fortune 500's, R&D Giants, Law firms, Universities, Research institutes & SME's Around The Globe Gather Intelligence That

Protects and Nurtures Innovation Through a Team of 250+ Techno Legal Professionals.