Hydrogen Engine Vehicles: Top Key Players and Their Products

BMW

About Company

The BMW name stands for Bayerische Motoren Werke GmbH. BMW was created in 1917 from the Munich firm Rapp-Motorenwerke. The company was incorporated into Knorr-Bremse AG in 1920 before being refounded as BMW AG in 1922. It was the successor of Bayerische Flugzeugwerke AG, founded in 1916. 1916 is therefore considered BMW's founding year.

The BMW Group remains on track for success, as you would expect from your Company. This held true once again in 2022, when we were able to sell a total of around 2.4 million vehicles. Even though the numbers are down slightly on the previous year, this is still an excellent result. Despite the geopolitical challenges and supply chain bottlenecks, BMW and MINI's global market share remained stable at 3.4 %. Our Rolls-Royce and BMW Motorrad brands posted new all-time highs, with more than 6,000 luxury motor cars and almost 203,000 motorcycles and scooters delivered to customers. BMW Motorrad thus earned the number-one spot in the global premium segment. To mark its 50th anniversary, our BMW M GmbH also celebrated a record year – with the all-electric BMW i4 M50 as the best-selling BMW M model.

In 2025, we will be taking a further leap with the introduction of the NEUE KLASSE. This tipping point heralds another typical BMW shift – towards a new product offering, a new mindset, a new company. Our Vision Vehicles already provide a glimpse of this, as we make individual mobility electric, digital and circular. What this means for us is NEXT LEVEL MOBILITY

- BMW Group has made 3 acquisitions across sectors such as Consumer Digital - DACH, Consumer Digital - Europe, Consumer Digital - Germany and others.

- The company has spent over $260M for acquisitions.

Patent Related to Hydrogen Engine Vehicles

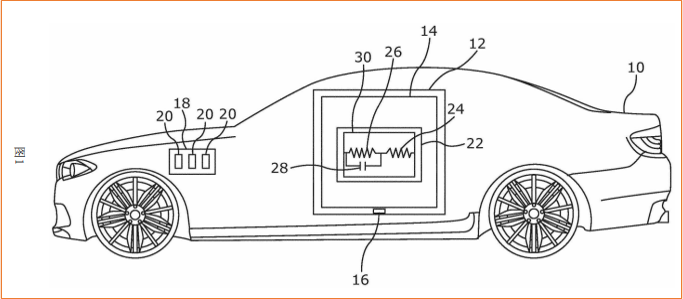

CN114747058A

- Title: Method for diagnosing at least one fuel cell stack of fuel cell device, computer-readable storage medium, and fuel cell diagnostic system

- Publication: 2022-07-12

- Coverage: CN

- Assignee: Bayerische Motoren Werke Ag

The technology disclosed herein relates to a method for diagnosing at least one fuel cell stack of a fuel cell device by means of a fuel cell diagnostic system. Further, the technology disclosed herein relates to a computer-readable storage medium and a fuel cell diagnostic system.

For example, provision may be made for diagnosing a hydrogen starvation in the fuel cell stack 20 if the capacitance 28 is determined to be decreasing and the second resistor 26 is held constant, or for diagnosing an oxygen starvation in the fuel cell stack 20 if the capacitance 28 is determined to be constant and the second resistor 26 is raised. For example, it can be provided that, in the event of a diagnosis of an insufficient hydrogen supply, the hydrogen can be supplemented accordingly by means of the regulation. Alternatively, the adjustment may be performed in case of insufficient oxygen supply, so that the oxygen may be supplemented. This makes it possible, for example, to increase the service life of the fuel cell system 18. Further, the performance of the fuel cell apparatus 18 can be improved and the fuel consumption can be reduced.

Product

BMW iX5 HYDROGEN

The BMW iX5 Hydrogen combines the typical BMW dynamics and agility with an innovative, groundbreaking hydrogen drive. Experience an uncompromising, electric driving experience with all the benefits of electricity from hydrogen. Its high range and short refuelling times make the BMW iX5 Hydrogen a pioneer in hydrogen-based, local emission-free mobility.

ELECTRIC DRIVING PLEASURE. WITH HYDROGEN.

- Fully refuelled in only 3-4 minutes for a range of up to 504 km

- Locally emission-free, powerful driving pleasure with up to 295 kW

- Carefree and flexible mobility even on long journeys

- Range and refuelling time independent of temperature

THE TECHNICAL DATA OF THE BMW iX5 HYDROGEN.

- Power: 295kW

- Combined capacity of the two hydrogen tanks (hydrogen – gaseous): 6kg

- Acceleration (0-100 km/h): <6s

- Top speed: >180 km/h

- Electric range (WLTP): 504km

- Hydrogen consumption, combined WLTP: 1.19 kg/100km

Read Also: Hydrogen Engine Vehicles: Overview & Working Principle

Nikola Corporation

About Company

Nikola Corporation, a leading designer and manufacturer of heavy-duty commercial battery-electric vehicles (BEV), fuel cell electric vehicles (FCEV), and energy infrastructure solutions, is paving the way as a global leader in zero-emissions transportation.

Through a business model that will enable corporate customers to integrate next-generation truck technology and hydrogen fueling infrastructure and maintenance, Nikola and its strategic business partners and suppliers are on a mission to leave the world a better place.

Nikola Corporation's mission is clear: pioneering solutions for a zero-emissions world. As an integrated truck and energy company, Nikola is transforming transportation and over-the-road freight services. With our Class 8 vehicles, including battery-electric and hydrogen fuel cell electric trucks, and our energy brand, HYLA, we are driving the advancement of the complete hydrogen refueling ecosystem. This encompasses supply, distribution, and dispensing, reflecting our commitment to sustainable practices and a cleaner future.

In Q4 2023, we delivered what we believe is the first production hydrogen fuel cell electric truck available in North America. We produced 42, delivering 35 of those to dealers and reserved seven for continued testing and fleet demos. Every truck delivered to dealers is spoken for by an end user, some of which are already utilizing the trucks in operations daily. End users include:

PHOENIX – February 5, 2024 – Nikola Corporation (Nasdaq: NKLA), a global leader in zero-emissions transportation and energy supply and infrastructure solutions, via the HYLA brand, proudly announces the opening of its first HYLA hydrogen refueling station in Southern Calif. Featuring an advanced modular fueler, the station at 2445 East Guasti Road in Ontario, Calif., represents the latest phase in Nikola's commitment to providing hydrogen refueling solutions for Class 8 trucks. View images and video of the refueling station.

Patent Related to Hydrogen Engine Vehicles

US2022111763A1

- Title: FUEL CELL VEHICLE THERMAL MANAGEMENT SYSTEM AND METHOD FOR MANAGING FUEL CELL THERMAL LOADS

- Publication: 2022-04-14

- Coverage: US

- Assignee: NIKOLA CORP

The present disclosure provides a method of managing thermal loads in a fuel cell vehicle. The method may comprise heating a fuel cell coolant of a fuel cell coolant loop utilizing waste heat from a fuel cell to form a heated fuel cell coolant, heating a battery coolant of a battery coolant loop utilizing waste heat from a battery to form a heated battery coolant, heating a refrigerant of a battery refrigeration loop by exchanging heat with the heated battery coolant, and superheating the refrigerant of the battery refrigeration loop by exchanging heat with the heated fuel cell coolant.

Accordingly, with reference to FIG. 1, a perspective view of a vehicle 100 incorporating a thermal management system is illustrated, in accordance with various embodiments. Vehicle 100 is a fuel cell electric vehicle incorporating an electric powertrain. More specifically, vehicle 100 is an electric commercial vehicle, such as, for example, a class 8 heavy duty commercial vehicle. While described herein as a fuel cell electric vehicle, vehicle 100 is not limited in this regard and may comprise any type, size, or function of vehicle. For example, vehicle 100 may comprise a battery electric vehicle, CNG vehicle, hythane vehicle, or any other suitable vehicle. Moreover, vehicle 100 may comprise a commercial vehicle of a different weight class or a passenger vehicle in various embodiments. It should be appreciated that vehicle 100 may comprise any vehicle type that can utilize a thermal management system wherein waste heat from certain system components may be at least partially salvaged and utilized in connection with a vapor-compression refrigeration loop as discussed in further detail below.

Product

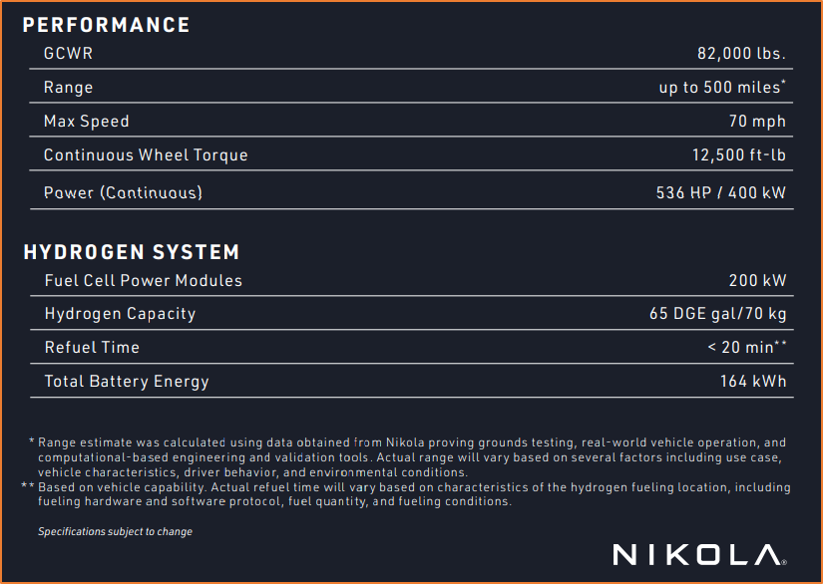

TRE FCEV

The Nikola FCEV is your partner in transport. Through its advanced interfaces, the driver can optimize travel time, fuel usage, and monitor vehicle systems. These advanced intuitive features deliver usability and performance that the competition cannot match.

General Motors

About Company

First locomotive

General Motors (GM), American corporation that was the world's largest motor-vehicle manufacturer for much of the 20th and early 21st centuries. It operates manufacturing and assembly plants and distribution centres throughout the United States, Canada, and many other countries. The company's major products include automobiles and trucks, automotive components, and engines, and it is also engaged in financial services. GM's headquarters are in Detroit.

Early history

Under the leadership of William C. Durant, the General Motors Company was founded in 1908 to consolidate several motorcar companies producing Buick, Oldsmobile, Cadillac, Oakland (later Pontiac), Ewing, Marquette, and other autos as well as Reliance and Rapid trucks. GM introduced the electric self-starter commercially in its 1912 Cadillac, and this invention soon made the hand crank obsolete. GM remained based in Detroit and was reincorporated and named General Motors Corporation in 1916. The Chevrolet auto company and Delco Products joined GM in 1918, and the Fisher Body Company and Frigidaire joined in 1919 (the latter was sold in 1979).

Durant was forced out of the company in 1920 and was succeeded by Alfred P. Sloan, Jr., who served as president (1923–37) and then as chairman of the board of directors (1937–56). Sloan reorganized GM from a sprawling, uncoordinated collection of business units into a single enterprise consisting of five main automotive divisions—Cadillac, Buick, Pontiac, Oldsmobile, and Chevrolet—the activities of which were coordinated by a central corporate office equipped with large advisory and financial staffs. The various operating divisions retained a substantial degree of autonomy within a framework of overall policy; this decentralized concept of management became a model for large-scale industrial enterprises in the United States. Sloan also greatly strengthened GM's sales organization, pioneered annual style changes in car models, and introduced innovations in consumer financing.

GM-Honda Begin Commercial Production at Industry's First Hydrogen Fuel Cell System Manufacturing Joint Venture.

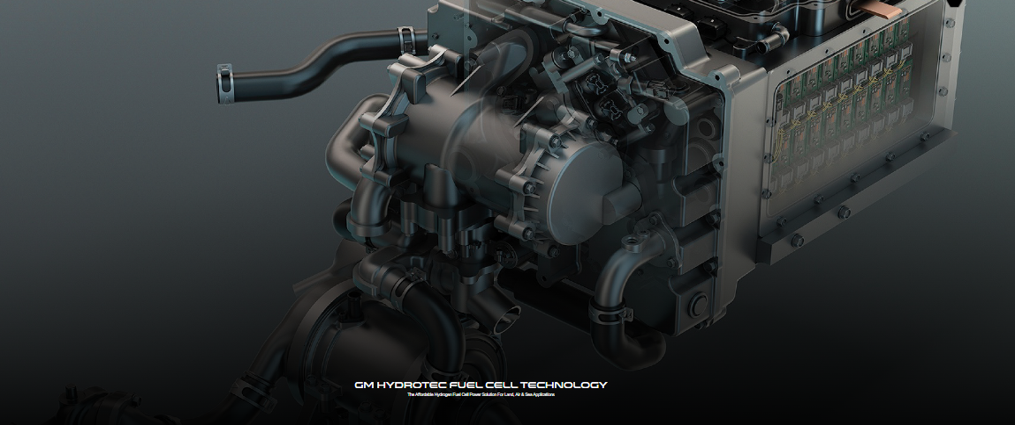

HYDROTEC

General Motors is the only company developing and commercializing both hydrogen fuel cells and EV battery technology, and the Ultium Platform and HYDROTEC fuel cell power cubes deliver where it matters most – performance and cost. This is opening new revenue potential for the company as industries – including freight trucking, aerospace, aircraft, locomotive – turn to GM for this technology to improve performance and reduce emissions.

The versatility of our technology can be used to power more than just consumer vehicles and has the potential to provide better energy solutions across industries on land, sea and air. We've made several ground-breaking announcements related to our HYDROTEC hydrogen fuel cells that demonstrate the rapid progress in monetizing our clean energy technologies and bulking up opportunities for recurring revenue beyond traditional vehicle sales.

Our vision for an all-electric future is rapidly advancing, and we're continuing to uncover new applications for our hydrogen fuel cell technology and demonstrate its broad appeal.

Collaborations

- NAVISTAR

- LIEBHERR

- WABTEC

CEO: Mary T. Barra

Headquarters: Detroit

Patent Related to Hydrogen Engine Vehicles

DE102005013519B4

- Title: Non-flammable exhaust gas release for hydrogen powered fuel cells and method for venting anode exhaust gas

- Publication: 2009-11-19

- Coverage: DE

- Assignee: GEN MOTORS CORP

These This invention relates generally to a hydrogen fuel cell system and more particularly, a hydrogen fuel cell system including a purge valve for rinsing a combustible anode exhaust gas from the fuel cell stack, a Accumulator for collecting the rinsed Anode exhaust and a drain valve for slowly draining the accumulated Anode exhaust gas from the accumulator in a non-combustible manner and used.

hydrogen represents a very attractive fuel source as it is clean is and efficient for generating electricity in a fuel cell can be used. The automotive industry applies significant Resources in the development of hydrogen fuel cells as an energy or power source for vehicles. such Vehicles would be more efficient and would generate less emissions than today's vehicles, the internal combustion engines use.

Furthermore, it is for example also from the DE 101 15 336 A1 or from the WO 00/39877 A1 known to promote by means of a pump, the anode exhaust gas back to the cathode inlet of a fuel cell stack. at certain fuel cell designs is a lower-level operation Anodenstöchiometrie for reasons one raised Efficiency of the system desired. In the case of an anode construction without drain, the anode discharge is closed, and the amount of hydrogen in the input gas is removed from the stack almost complete consumed. However, an anode operation without expiration requires a periodic one do the washing up the anode to a nitrogen as well as water accumulation in the Minimize stacks. If the anode is not periodically purged, then reduce accumulated nitrogen and accumulated water in the stack the efficiency of the stack and finally effect that Shutdown. The rinsed Anode exhaust gas includes hydrogen, which is usually vented to the atmosphere or is delivered to the exhaust gas burner.

Product

HYDROTEC

Wabtec and gm to develop advanced ultium battery and hydrotec hydrogen fuel cell solutions for rail industry

Wabtec Corporation (NYSE: WAB) and General Motors (NYSE: GM) today announced they will collaborate to develop and commercialize GM's Ultium battery technology and HYDROTEC hydrogen fuel cell systems for Wabtec locomotives."The rail industry is on the cusp of a sustainable transformation with the introduction of batteries and hydrogen to power locomotive fleets," said Rafael Santana, CEO and president of Wabtec. "Our FLXdrive locomotive, the world's first 100-percent battery powered locomotive, has proven its potential to slash carbon emissions by up to 30 percent when operating at 6 MWh. But we can't stop there.

By working with GM on Ultium battery and HYDROTEC hydrogen fuel cell technologies, we can accelerate the rail industry's path to decarbonization and pathway to zero-emission locomotives by leveraging these two important propulsion technologies. "Wabtec and GM signed a nonbinding memorandum of understanding to advance the two companies' shared vision of a zero-emissions future in transportation. Wabtec will bring its expertise in energy management and systems optimization to develop a solution for heavy haul locomotives that takes full advantage of GM's advanced technologies. "Rail networks are critical to transportation and to GM's ability to serve our customers across North America, and Wabtec's bold plan to de-carbonize heavy haul and other locomotive applications helps advance our vision of a world with zero crashes, zero emissions and zero congestion," said Mark Reuss, GM president. "Wabtec's decision to deploy GM's Ultium battery and HYDROTEC hydrogen fuel cell systems further validates our advanced technology and demonstrates its versatility. "GM's Ultium battery technology is anticipated to provide the flexibility, efficiency, power and reliability needed for rail. Ultium Cells LLC, GM's joint venture with LG Energy Solution, is currently constructing battery cell plants in Ohio and Tennessee.GM's HYDROTEC hydrogen fuel cell power cubes are compact and easy to package and can be used in a wide range of applications, including locomotives. HYDROTEC fuel cell systems will be assembled from globally sourced parts by Fuel Cell Systems Manufacturing, LLC in Brownstown, Michigan, the manufacturing joint venture between General Motors and Honda.

Tata Motors

About Company

First locomotive

In 1945, Tata Motors (previously known as Tata Engineering and Locomotive Company (TELCO)) embarked on its journey by manufacturing locomotives. During the same year, Tata Sons formally acquired the E.I. Railway Workshop and was assigned the responsibility of assembling 5,000 imported wagons on behalf of the Railway Board.

First indigenous heavy-duty truck

In 1954, an agreement with Daimler-Benz led to the rollout of the first Tata Mercedes-Benz truck. It introduced the world to the first-ever 'heavy-duty truck' to be made on Indian soil. A landmark partnership between two iconic brands sowed the seeds of automotive manufacturing in the country.

First electric SUV

In 2020, Tata Motors introduced the 'New Forever' range of passenger vehicles. The Nexon EV, equipped with state-of-the-art Ziptron technology, seamless connectivity, long range and competitive pricing, emerged as India's most popular EV, setting a new standard.

Patent Related to Hydrogen Engine Vehicles

EP2683971B1

- Title: A self regulating air throttle valve, method of regulating air, and method of assembling thereof

- Publication: 2015-06-17

- Coverage: EP

- Assignee: Tata Motors Ltd

Embodiments of the present disclosure relate to air throttle valve, more particularly relates to self regulating air throttle valve used in fuel cell.

Accordingly, the present disclosure provides for a self regulating air throttle valve (1), comprising a male plunger (2) and a female plunger (3) of predetermined shapes; a helical spring (7) supporting the male plunger (2) at one end of the spring (7) and other end of the spring is fixed to a flange (14); a plunger guide (4) passing through the helical spring (7) and attached to the flange (14) at one end using fasteners (15) and other end is passed through the male plunger (2); a manifold (5) comprising one or more breathing ports (6) on its surface, said manifold (5) is configured to house said male (2) and said female plungers (3); and an outer cover (8), housing the manifold (5), wherein said outer cover (8) is attached with an inlet manifold (9) at top of the outer cover (8) and an outlet manifold (10) at bottom of the outer cover (8), wherein said male plunger (2) is regulated by force of compressed air supplied through the inlet manifold (9) and reverse force of the helical spring (7) to vary rate of opening of the breathing ports (6) to regulate the air throttle valve, also provides for a method of regulating air using a self regulating air throttle valve (1), said method comprising act of exerting pressure of air onto a male plunger (2) through inlet manifold (10) using a compressor, wherein reverse force generated by helical spring regulates movement of male plunger (2) for varying opening of breathing ports (6) for regulating air through the valve (1), and also provides for a method of assembling a self regulating air throttle valve (1), said method comprising acts of supporting a helical spring (7) to male plunger (2) at one end of the helical spring (7) and fixing other end of the spring to a flange (14); passing a plunger guide (4) through the helical spring (7) and attaching to the flange (14) at one end using fasteners (15) and passing other end of the plunger guide through the male plunger (2); connecting a female plunger to a flange (12); mounting a manifold (5) to house said male (2) and said female plungers (3) using fasteners (16); attaching an outer cover (8) to the manifold (5) through the flange (12) to house the manifold (5); and fixing an inlet manifold (9) at top of the outer cover (8) and an outlet manifold (10) at bottom of the outer cover (8) through flanges (12, 13).

Product

FCEV Buses

Tata Motors delivers first-of-its-kind Hydrogen Fuel Cell powered buses to Indian Oil

Shri Hardeep Singh Puri, Hon'ble Union Minister for Petroleum & Natural Gas and Housing & Urban Affairs, Shri Rameswar Teli, Union Minister of State for Petroleum & Natural Gas and Labour & Employment, Shri Pankaj Jain, Secretary, Ministry of Petroleum & Natural Gas, Shri S M Vaidya, Chairman, IOCL, Dr. Umish Srivastva, Executive Director, IOCL, and Mr. Rajendra Petkar, President & Chief Technology Officer, Tata Motors, flagged-off India's first green hydrogen FCEV.

Tata Motors, India's largest commercial vehicle manufacturer, today made a giant leap forward in its commitment to move India forward with smarter and greener mobility solutions by delivering first-of-its-kind Hydrogen Fuel Cell powered (FCEV) buses to Indian Oil Corporation Ltd. (IOCL), the country's largest petroleum company. Heralding a new era of fully decarbonised transport, two buses were flagged-off by Shri Hardeep Singh Puri, Hon'ble Union Minister for Petroleum & Natural Gas and Housing & Urban Affairs, Shri Rameswar Teli, Union Minister of State for Petroleum & Natural Gas and Labour & Employment, Shri Pankaj Jain, Secretary, Ministry of Petroleum & Natural Gas, Shri S M Vaidya, Chairman, IOCL, Dr. Umish Srivastva, Executive Director, IOCL, and Mr. Rajendra Petkar, President & Chief Technology Officer, Tata Motors, along with delegates from Government of India, Government of New Delhi and Tata Motors.Speaking about the successful deployment of first-of-its-kind FCEV bus, Mr. Girish Wagh, Executive Director, Tata Motors, said, This is an outcome of the progressive policies of the Government, IOCL's focus on future readiness and Tata Motors' R&D prowess, all collaborating to fulfil the common vision of clean mobility in India. The delivery of the FCEV buses to IOCL marks a significant step forward in this journey and we are grateful for the trust and support of our partners. At Tata Motors, we always prioritise nation building and are leading the global megatrend of sustainable, connected, and safer mobility in the country. The delivery of these buses today heralds a new era in inter-city mass public transport and marks another step forward towards fulfilling the aspiration of sustainable mobility. With proactive actions to develop and adapt new age technologies, we are creating future-ready transport solutions for both cargo and people to address the mobility needs of tomorrow's India, today.In June 2021, Tata Motors had won a tender from IOCL to provide 15 FCEV buses to evaluate the potential of hydrogen-based PEM fuel-cell technology in India. These buses are to be assessed as potential mass transport solution for inter and intra-city commute.Built at a dedicated lab in Tata Motors' world class R&D centre at Pune, these 12-metre long buses are designed for easy ingress and egress with a low-floor design, can seat 35 passengers and were delivered after successful strenuous road tests and validations. Expertise and experiences was acquired by Tata Motors from a collaborative approach with renowned industry partners and research institutions, for adapting the advanced hydrogen-based proton exchange membrane (PEM) fuel cell technology to Indian conditions, and has played a key role in developing the buses

Hyundai Motor Company

About Company

Hyundai Motor Company has served as the trailblazer of Korea's automobile industry since rolling out its Pony, developed with its own exclusive technology. Hyundai Motor Company has risen as a globally recognized automobile manufacturer that exports its branded vehicles to over 200 countries. It is equipped with production bases all around the world. It is expanding the automobile market through its success in mass-producing hydrogen-powered vehicles for the first time in the world and launching GENESIS, a high-end brand, while propelling the future mobility industry forward based on its leadership in autonomous driving and connectivity technologies. It seeks to find better solutions for humanity by achieving technological innovation under the aim of "Progress for Humanity".

First indigenous heavy-duty truck

Chung Ju-yung (1915–2001) founded the Hyundai Engineering and Construction Company in 1947. Hyundai Motor Company was later established in 1967, and the company's first model, the Cortina, was released in cooperation with Ford Motor Company in 1968. When Hyundai wanted to develop their own car, they hired George Turnbull in February 1974, the former managing director of Austin Morris at British Leyland. He in turn hired five other top British car engineers. They were body designer Kenneth Barnett, engineers John Simpson and Edward Chapman, John Crosthwaite, formerly of BRM, as chassis engineer and Peter Slater as chief development engineer.

Production of Hydrogen Fuel cell enabled Vehicles

Hyundai Motor has secured world class eco-friendly technologies in preparation for the shift to electrified vehicles. In 2013 it began mass production of a hydrogen fuel cell electric vehicle (FCEV), the Tucson (ix35), for the first time in the world, proving its technological expertise in this field. In 2018, the company launched NEXO FCEV, a fuel cell electric car that can run over 580 kilometers on a single charge. Hyundai Motor has also proven itself to be a leader in the area of autonomous driving, with its Autonomous Ioniq Electric vehicle achieving a level 4 standard by Society of Automotive Engineers (SAE) after completing a self driving performance in real road conditions in January 2017. Hyundai Motor will do its utmost to secure competitiveness in future mobility business areas through active investment and collaboration with global information and communications (ICT) leaders and related research institutes.

Patent Related to Hydrogen Engine Vehicles

US8268139B2

- Title: Hydrogen generation apparatus

- Publication: 2012-09-18

- Coverage: US

- Assignee: Hyundai Motor Co Ltd

The present invention relates to a hydrogen generation apparatus using chemical hydride. The present invention features an electrolyte including chemical hydride and a catalyst that is inserted between metal electrodes, wherein the hydrogen is generated in a unit cell by hydrolysis of the hydride.

Preferably, the hydrogen generation apparatus of the present invention may be suitably prepared in the form of a cartridge, and thus the vehicle may preferably be driven by simply replacing a used cartridge with a new one instead of the conventional high-pressure hydrogen charging. Thus, in preferred embodiments, the complex charging system of the hydrogen charging method is no more necessary. Further, the conventional hydrogen charging station is not needed with this preferred method, and the installation and the construction cost of the hydrogen charging station, which has been a limiting factor for the propagation of the fuel cell vehicles, may be solved. Preferably, in the hydrogen generation apparatus of the present invention, a water supply means, which supplies water for the hydrolysis, additionally supplies the water exhausted from the fuel cell stack to each unit cell continuously. Thus, the efficiency for the hydrolysis may be increased, and the hydrogen generation may be suitably increased. In case the hydrogen generation apparatus of the present invention is suitably prepared in the form of a cartridge, the cartridge regeneration process for supplementing water and removing by-product is needed, but the replacement cycle of cartridges may be extended because the water is provided continuously from the stack by the water supply means during the fuel cell operation. Preferably, when the housing of the hydrogen generation apparatus of the present invention is formed as a suitable openable structure, the by-product of the hydrolysis may be removed easily during the regeneration after use. Preferably, the additional hydrogen storage container may suitably solve the problem that the hydrogen should be released to the outside when the pressure in the housing is suitably increased. The hydrogen of the hydrogen storage container may be provided to stack immediately after starting the fuel cell. Especially, the hydrogen generated at the unit cell is stored in the hydrogen storage container and is used immediately upon necessity. The hydrogen is stored in the hydrogen storage container if not needed. It is understood that the term "vehicle" or "vehicular" or other similar term as used herein is inclusive of motor vehicles in general such as passenger automobiles including sports utility vehicles (SUV), buses, trucks, various commercial vehicles, watercraft including a variety of boats and ships, aircraft, and the like, and includes hybrid vehicles, electric vehicles, plug-in hybrid electric vehicles, hydrogen-powered vehicles and other alternative fuel vehicles (e.g. fuels derived from resources other than petroleum).

Product

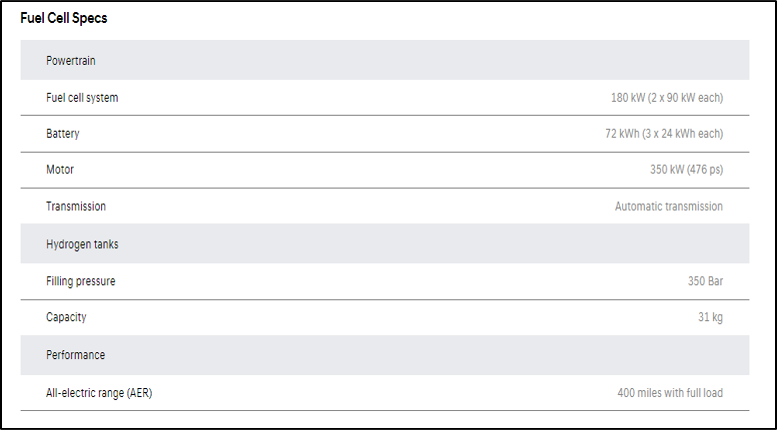

XCIENT Fuel Cell

In 2020, HMC exported its first consignment (47 units) of hydrogen-powered, zero-emission electrified commercial vehicles, XCIENT Fuel Cell to Switzerland. They are currently in use by logistics, distribution, and retail fleet operators.

Toyota Motor

About Company

Toyota Motor is a Japanese multinational automotive manufacturer headquartered in Toyota City, Aichi, Japan. It was founded by Kiichiro Toyoda and incorporated on August 28, 1937. Toyota is the largest automobile manufacturer in the world, producing about 10 million vehicles per year. The company was originally founded as a spinoff of Toyota Industries, a machine maker started by Sakichi Toyoda, Kiichiro's father. Both companies are now part of the Toyota Group, one of the largest conglomerates in the world. While still a department of Toyota Industries, the company developed its first product, the Type A engine, in 1934 and its first passenger car in 1936, the Toyota AA. In the 1960s, Toyota took advantage of the rapidly growing Japanese economy to sell cars to a growing middle-class, leading to the development of the Toyota Corolla, which became the world's all-time best-selling automobile.

First true Japanese passenger car

Toyota's first passenger car is the Toyoda Model AA passenger car, which was designed in 1935 using the Chevrolet and the Desoto as a reference. This was listed in the catalogue as a standard sedan, but that meant standard from the viewpoint of an advanced automotive country like the United States. Given the conditions in Japan at the time, this was a large passenger car and couldn't be called 'standard'.The Model AA passenger car unmistakably formed the basis for subsequent car design and manufacturing technology however, and Toyota Motor Co., Ltd. independently developed Japan's first true passenger car, Toyopet Crown, based on this technology. In other words, with the arrival of the Crown the first standard sedan was created that was suited to Japanese conditions.

The Toyota Mirai

Toyota began development of hydrogen FCEVs way back in 1992. We successfully introduced the Mirai sedan to world markets in 2014. The latest generation Mirai, launched in 2021, takes FCEV technology to a higher level. Its comprehensively redesigned fuel cell system is lighter and more powerful. Combined with intelligent packaging and improved aerodynamic efficiency it has extended the driving range to around 650 km, with no emissions other than pure water.

Patent Related to Hydrogen Engine Vehicles

US11721819B2

- Title: Fuel cell system and air vehicle

- Publication: 2023-08-08

- Coverage: US

- Assignee: Toyota Motor Co Ltd

A fuel cell system for air vehicles, wherein the fuel cell system comprises: a fuel cell, a fuel gas system for supplying fuel gas to the fuel cell, a potential sensor, and a controller; wherein the fuel gas system comprises a fuel gas supplier; wherein the controller determines whether or not a potential of the fuel cell measured by the potential sensor, is a reversal potential; and wherein, when the controller determines that the potential of the fuel cell is a reversal potential, the controller increases a fuel gas supply from the fuel gas supplier to the fuel cell.

The fuel cell system of the present disclosure is a fuel cell system for air vehicles, wherein the fuel cell system comprises: a fuel cell, a fuel gas system for supplying fuel gas to the fuel cell, a potential sensor, and controller; wherein the fuel gas system comprises a fuel gas supplier; wherein the controller determines whether or not a potential of the fuel cell measured by the potential sensor, is a reversal potential; and wherein, when the controller determines that the potential of the fuel cell is a reversal potential, the controller increases a fuel gas supply from the fuel gas supplier to the fuel cell. In the present disclosure, the fuel gas and the oxidant gas are collectively referred to as "reaction gas". The reaction gas supplied to the anode is the fuel gas, and the reaction gas supplied to the cathode is the oxidant gas. The fuel gas is a gas mainly containing hydrogen, and it may be hydrogen. The oxidant gas may be oxygen, air, dry air or the like. The fuel cell system of the present disclosure is mounted and used in an air vehicle. The fuel cell system of the present disclosure may be mounted and used in an air vehicle that can fly by the power of a secondary cell. The air vehicle of the present disclosure may be an aircraft. The aircraft may be an airplane, a vertical takeoff and landing aircraft or the like. The vertical takeoff and landing aircraft may be a helicopter, a drone or the like. The air vehicle may include the fuel cell system of the present disclosure. The fuel cell system of the present disclosure includes the fuel cell. The fuel cell may be a fuel cell composed of only one unit fuel cell, or it may be a fuel cell stack composed of stacked unit fuel cells. The number of the stacked unit fuel cells is not particularly limited. For example, 2 to several hundred unit fuel cells may be stacked, or 2 to 600 unit fuel cells may be stacked. The fuel cell stack may include an end plate at both stacking-direction ends of each unit fuel cell. Each unit fuel cell includes at least a membrane electrode gas diffusion layer assembly. The membrane electrode gas diffusion layer assembly includes an anode-side gas diffusion layer, an anode catalyst layer, an electrolyte membrane, a cathode catalyst layer, and a cathode-side gas diffusion layer in this order. The cathode (oxidant electrode) includes the cathode catalyst layer and the cathode-side gas diffusion layer. The anode (fuel electrode) includes the anode catalyst layer and the anode-side gas diffusion layer.

Product

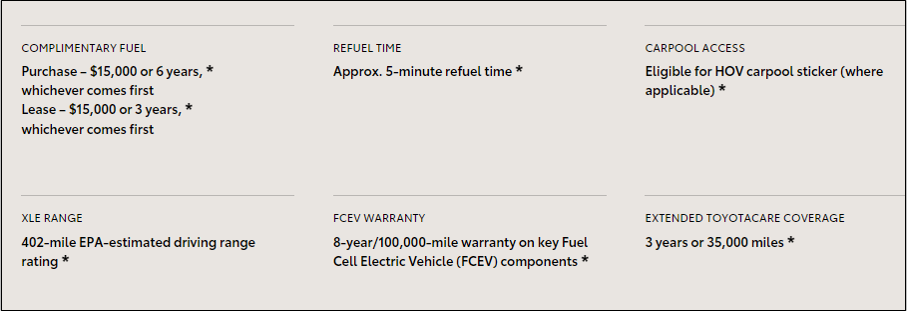

2024 Mirai

Mirai's hydrogen fuel tanks have been rigorously tested and proven to meet Global Technical Regulation No. 13. * If the hydrogen sensors detect a leak or a collision, the hydrogen tank valves will automatically close to prevent more hydrogen from escaping while any hydrogen that is leaked will safely return to the atmosphere.

When fully fueled with hydrogen, the 2024 Mirai XLE has an impressive EPA-estimated 402-mile driving range rating * and the 2024 Mirai Limited has an EPA-estimated 357-mile driving range rating. * Driving in the city or cruising down the curvy roads, Mirai’s dynamic rear-wheel-drive platform consistently delivers an exciting, zero-emissions ride.

Volvo

About Company

Volvo Cars is a Swedish multinational manufacturer of luxury vehicles. Volvo is headquartered in Torslanda, Gothenburg. The company manufactures SUVs, station wagons, and sedans. The company's main marketing revolves around safety and its Swedish heritage and design. Volvo Cars has been separate from its former parent conglomerate and producer of heavy trucks, buses, and construction equipment (among others) AB Volvo since 1999 when AB Volvo sold its automobile division Volvo Cars to Ford Motor Company. On 28 March 2010, Ford sold Volvo Cars at a loss to Geely for $1.8 billion; the deal closed in August 2010. Volvo Cars was publicly listed on the Nasdaq Stockholm stock exchange in 2021, though Geely still retains majority ownership. Volvo Cars and AB Volvo share the Volvo logo, and cooperate in running the Volvo Museum. In March 2021, Volvo Cars announced that it would be a fully electric brand by 2030. In June 2021, Volvo Cars and Swedish battery developer and manufacturer Northvolt announced the intention to establish a 50/50 joint venture consisting of a battery gigafactory and R&D (research and development) center. In December 2021, it was revealed the battery R&D center would be located in Gothenburg.

ÖV4 On the morning of 14 April 1927, the first Volvo car drove out through the factory gates in Gothenburg on the west coast of Sweden. The car was officially called the ÖV4 and it was an open tourer with a four-cylinder engine. The world's first Volvo was ready to hit the road.

1944 – The “little Volvo” comes along On 1 September 1944, the car that would make Volvo an international car company was unveiled in Stockholm. “The little Volvo”, as it was called, was seen in Sweden as a promise of post-war prosperity and in the course of two weeks 2,300 people placed orders for the PV 444.

Volvo Cars starts development of fuel cells to extend the electric car's operating range

Volvo Cars is now taking the next step towards next-generation electric car technology. Backed by research support from the Swedish Energy Agency the company is initiating development of a fuel cell that can extend the electric car's operating range without any carbon dioxide emissions. The aim is to have two prototype chassis based on the Volvo C30 DRIVe Electric ready for testing in everyday traffic in 2012. "This is an exciting expansion of our focus on electrification. Battery cost and size means that all-electric cars still have a relatively limited operating range. Fuel cells may be one way of extending the distance these cars can cover before they need to be recharged. What is more, the project gives us increased knowledge about fuel cells and hydrogen gas," says Volvo Cars President and CEO Stefan Jacoby.

Patent Related to Hydrogen Engine Vehicles

WO2022253439A1

- Title: A cooling arrangement for a fuel cell electric vehicle

- Publication: 2022-12-08

- Coverage: WO

- Assignee: Volvo Truck Corp

The invention relates to a cooling arrangement for a fuel cell electric vehicle, comprising: a hydrogen tank comprising a metal enveloping wall, a heat exchanger comprising a metal part with at least one internal coolant channel (8) for conducting a coolant to fuel cells of the vehicle, wherein the metal enveloping wall of the hydrogen tank has at least one planar exterior wall portion, wherein the metal part of the heat exchanger is attached to said planar exterior wall portion of the hydrogen tank to form a metal-to-metal contact for transferring heat from the coolant, via the metal part of the heat exchanger, to the metal enveloping wall of the hydrogen tank. The invention also relates to a fuel cell electric vehicle comprising such a cooling arrangement.

The advantages of the FCEV of the second aspect of the present disclosure largely corresponds to the advantages of the cooling arrangement of the first aspect, including any embodiment thereof.

Thus, according to a first aspect of the present disclosure there is provided a cooling arrangement for a fuel cell electric vehicle (FCEV). The cooling arrangement comprises:

The vehicle 100 further comprises a heat exchanger 132 and a cooling passage 130 for circulating a coolant, i.e. a cooling liquid, such as for example water. The cooling passage 130 extends from the heat exchanger 132 and passes along the stack of fuel cells 110 for transporting heat away from the stack of fuel cells 110.

Product

Hydrogen Fuel Cell Truck

- Volvo Trucks showcased its fuel cell electric trucks for the first time. The zero-emission trucks use hydrogen to produce their own electricity onboard, making them suitable for longer transport assignments.

- Last year, Volvo Trucks showcased its fuel cell electric trucks for the first time. The zero-emission trucks use hydrogen to produce their own electricity onboard, making them suitable for longer transport assignments.

- Now, the trucks have been tested on public roads for the first time. To make the tests extra challenging, they have been conducted above the Arctic Circle in the north of Sweden – in an extremely cold climate.

- Fuel cell electric trucks powered by hydrogen will be especially suitable for longer distances and when using only batteries isn’t an option: for example, in rural areas with no charging infrastructure.

- Volvo’s hydrogen-powered fuel cell trucks will use two fuel cells with a capacity to generate 300 kW of electric power.

- Green hydrogen is an endless resource that is produced by using renewable energy sources, such as wind, water and sun.

Mercedes

About Company

Mercedes-Benz Group AG is one of the world's most successful automotive companies. With Mercedes-Benz AG, the Group is one of the leading global suppliers of high-end passenger cars and premium vans. Mercedes-Benz Mobility AG offers financing, leasing, car subscription and car rental, fleet management, digital services for charging and payment, insurance brokerage, as well as innovative mobility services. The company founders, Gottlieb Daimler and Carl Benz, made history by inventing the automobile in 1886. As a pioneer of automotive engineering, Mercedes[1]Benz sees shaping the future of mobility in a safe and sustainable way as both a motivation and obligation. The company's focus therefore remains on innovative and green technologies as well as on safe and superior vehicles that both captivate and inspire. Mercedes-Benz sells its vehicles and services in nearly every country of the world and has production facilities in Europe, North and Latin America, Asia and Africa .In addition to Mercedes-Benz, the world's most valuable luxury automotive brand Mercedes-AMG, Mercedes-Maybach, and Mercedes me as well as the brands of Mercedes-Benz Mobility: Mercedes-Benz Bank, Mercedes-Benz Financial Services and Athlon.

The first automobile The first stationary gasoline engine developed by Carl Benz was a one-cylinder two-stroke unit which ran for the first time on New Year’s Eve 1879. Benz had so much commercial success with this engine that he was able to devote more time to his dream of creating a lightweight car powered by a gasoline engine, in which the chassis and engine formed a single unit.

Long-distance journey by Bertha Benz (1888) Using an improved version and without her husband’s knowledge, Benz’s wife Bertha and their two sons Eugen (15) and Richard (14) embarked on the first long-distance journey in automotive history on an August day in 1888.

First Mercedes-Benz GenH2 Daimler Truck is entering the next development phase on the road to decarbonize transportation with hydrogen-powered trucks. After a rigorous testing phase on the test track and on public roads, the fuel-cell trucks have now reached an advanced development stage for deployment in first customer fleets. Consequently, Daimler Truck is now taking the next step by building a first customer-trial fleet of Mercedes-Benz GenH2 Trucks. Expected from mid-2024, the companies Amazon, Air Products, INEOS, Holcim and Wiedmann & Winz will take part in first customer trials to gain initial experience in CO2-free long-distance transport with fuel-cell trucks.

Patent Related to Hydrogen Engine Vehicles

DE102023002549A1

- Title: Drive module and vehicle with such a drive module

- Publication: 2023-08-17

- Coverage: DE

- Assignee: Mercedes Benz Group Ag

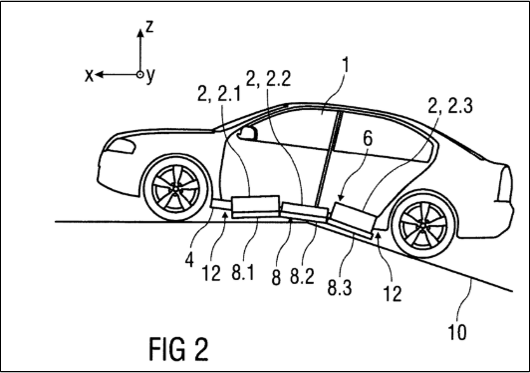

The invention relates to a drive module (2) for an electrically operated vehicle (1) or a hybrid vehicle with a module housing (6) for accommodating a drive, wherein the module housing (6) is constructed as a modular housing frame (8) which has at least three frame parts (8.1 to 8.3), which are adjustable and/or movably coupled to one another.

The drive module can, for example , be a high-voltage battery with a single cell or a rechargeable galvanic element or a rechargeable battery, in particular a lithium-ion cell or solid-state cell, or with a plurality of battery cells and/or a number of battery cell stacks, each from a plurality of Battery cells, or a fuel cell module (also fuel cell stack) or a hydrogen tank. The drive module is in particular a battery module or a fuel cell module for supplying electrical energy to at least one electric drive motor for driving a vehicle, in particular an electric vehicle or a hybrid vehicle. The module housing is used to hold the battery module or the fuel cell module.By means of a modular housing frame with adjustable and/or movably coupled frame parts , damage to the module housing when driving over obstacles or when driving up or down a curb can at least be reduced or even avoided. In addition, the invention enables the installation space under the vehicle or a total installation space (also called package) required for the installation situation of the drive module, taking into account the desired ground clearance and/or a determined ramp angle of the vehicle, to be used much better than is the case with vehicle batteries or energy storage or similar drive modules of conventional “straight” design (“skate board” architecture). In addition, due to the modular housing frame, the invention enables flexible and arbitrarily combinable integration of different drive modules, such as battery cells and/or different “power packs” with different storage media, for example battery modules, fuel cell modules, hydrogen tanks, flat storage units or the like.In a possible embodiment , two adjacent frame parts are coupled to one another in an articulated manner. For example, two adjacent frame parts can be coupled to one another by means of a rotatably mounted double hinge. In addition, at least one fastening plate and/or one cladding plate can be arranged and fastened to the respective frame part.In a possible embodiment , the drive module has a plurality of drive units.In a possible embodiment , the drive module has a first drive unit in the form of a hydrogen tank arrangement, a second drive unit in the form of a battery module, and a third drive unit in the form of a hydrogen tank arrangement.The vehicle according to the invention includes the previously described drive module. The respective double hinge can also be attached/attached to a vehicle side member.

Product

Mercedes-Benz GLC F-CELL (model series X 253).

The Mercedes-Benz GLC F-CELL (combined hydrogen consumption: 0.34 kg/100 km, combined CO₂ emissions: 0 g/km, combined power consumption: 13.7 kWh/100 km)** ) meets the highest standards with regard to safety, comfort, agility, and design, and was also analysed comprehensively in terms of its environmental impact over the entire lifecycle. When it comes to the overall life cycle assessment, however, the GLC F-CELL benefits from continuous locally emission-free operation and the high efficiency of the electric powertrain.

Unique Hybrid Combination

he Mercedes-Benz GLC F-CELL is a unique plug-in hybrid as it combines innovativefuel[1]cell and battery technologies for the first time: apart from electricity, it alsoruns on pure hydrogen.

Intelligent interplay between battery and fuel cell, long range, and short refueling times make the GLC F[1]CELL a vehicle of high everyday practicality and also suitable for short and long-distance motoring. The GLC F-CELL represents an important step by Mercedes-Benz in the development of fuel cell technology. It features a totally new fuel cell system which is so compact that the entire system can be housed in the engine compartment for the first time and installed at the same mounting points as a conventional engine. In addition, the use of platinum in the fuel cell has been reduced by 90 percent in comparison to the predecessor generation. Consequently resources are conserved, and system costs are cut without impairing performance. The lithium-ion battery has a gross capacity of 13.5 kWh and additionally serves as an energy source for the electric motor. Plug-in technology makes it easy to charge via the 7.4 kW on[1]board charger at a standard household socket, a wall box or a public charging station – from 10 to 100 percent SoC (State of Charge) in approx. 1.5 hours if the full power is used. Just like the drive motor, an asynchronous motor with an output of 155 kW (211 hp) and a torque of 365 Nm, the powerful storage battery is space savingly installed in the rear of the SUV. Two carbon-fibre-encased tanks built into the vehicle floor hold 4.4 kg of hydrogen. Thanks to globally standardized 700-bar tank technology, the supply of hydrogen can be replenished within just three minutes - as quickly as is customary when refueling a combustion-engined car.

Read Also: Hydrogen Engine Vehicles: Market Insights and Key Players

About Effectual Services

Effectual Services is an award-winning Intellectual Property (IP) management advisory & consulting firm offering IP intelligence to Fortune 500 companies, law firms, research institutes and universities, and venture capital firms/PE firms, globally. Through research & intelligence we help our clients in taking critical business decisions backed with credible data sources, which in turn helps them achieve their organisational goals, foster innovation and achieve milestones within timelines while optimising costs.

We are one of the largest IP & business intelligence providers, globally serving clients for over a decade now. Our multidisciplinary teams of subject matter experts have deep knowledge of best practices across industries, are adept with benchmarking quality standards and use a combination of human and machine intellect to deliver quality projects. Having a global footprint in over 5 countries helps us to bridge boundaries and work seamlessly across multiple time zones, thus living to the core of our philosophy - Innovation is global, so are we !!!

Solutions Driving Innovation & Intelligence

Enabling Fortune 500's, R&D Giants, Law firms, Universities, Research institutes & SME's Around The Globe Gather Intelligence That

Protects and Nurtures Innovation Through a Team of 250+ Techno Legal Professionals.