Decarbonisation in Steel Manufacturing: Hydrogen Flash Steelmaking System

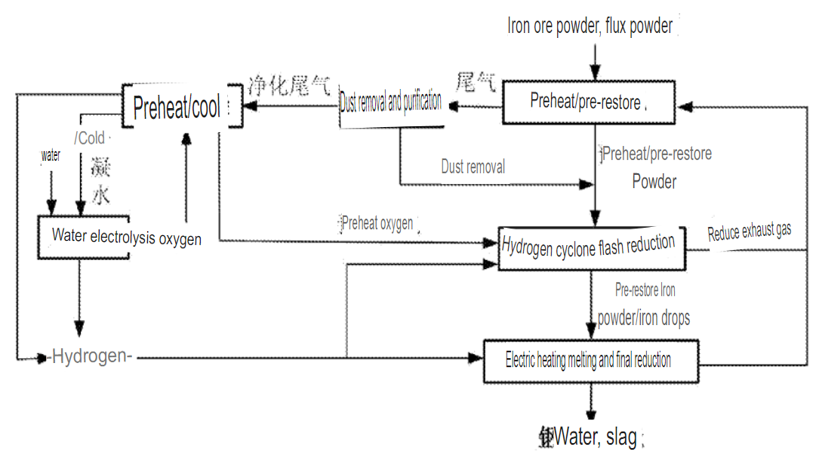

Electric energy full-hydrogen flash reduction direct steelmaking system and process which is a decarbonisation technology focuses carbon direct avoidance pathway. The system comprises an electrolyzed water hydrogen production device, a cyclone flash reduction furnace, an electric melting furnace, and exhaust gas post-treatment equipment. The described system and process offer advanced features such as the use of electric energy, no pollutant emissions, cyclic raw material utilization, clean smelting, high metallization rates, and no CO2 emissions. These features collectively contribute to a more sustainable and environmentally friendly approach to smelting.

Electric Energy Full-hydrogen Flash Reduction Direct Steelmaking System and Process

The Solution to the Problem is Developed by Northeastern University

Technology Summary

System: The system comprises an electrolytic water hydrogen production device, a cyclone flash reduction furnace, an electric heating melting furnace, and a tail gas post-treatment device.

Process: The process is as follows: hydrogen serving as reducing gas and oxygen are prepared by water electrolysis; the oxygen and steelmaking powder are sprayed into the cyclone flash reduction furnace, and meanwhile, the hydrogen is blown into the lower part thereof; the gas and solid phases undergo a reduction reaction at 500-1500°C during the countercurrent movement in the cyclone furnace to obtain pre-reduced iron powder/iron droplets having a metallization ratio greater than 80% which enter the electric heating melting furnace for melting; the hydrogen is blown into the bottom of the electric heating melting furnace to be stirred and molten for final reduction, and continuous steelmaking is carried out; tail gas is reduced and molten, and the power is pre-heated/pre-reduced, and dust removal purification is carried out; the tail gas is purified, the oxygen is preheated, and condensation separation is carried out; the hydrogen returns to the cyclone flash reduction furnace and condensed water returns to electrolytic water to produce hydrogen.

Advanced Features and Application

- The process completely utilizes electric energy for smelting without relying on fossil fuel

- Completely uses hydrogen as a reducing agent, and has no pollutant emission in the process,

- Enable efficient and cyclic utilization of raw materials, and clean smelting.

- Beneficial to obtain high metallization rate.

- Reduced iron powder; hydrogen reduction product is water vapor, no CO2 emissions,

- Water vapor can be returned to the electrolyzed water hydrogen production system for recycling, which not only reduces the environmental load, but also achieves cleaner production;

- The invention makes full use of fine ore resources, gets rid of coking, sintering, pelletizing and other processes,

- Does not require converter decarburization, thereby simplifies the steelmaking process,

Steel Making Process

Arrangement of Electric Energy Full-hydrogen Flash Reduction Direct Steelmaking System

System

The present invention provides a direct steelmaking system for electric energy full hydrogen flash reduction.

- The system includes: an electrolyzed water hydrogen production device, a cyclone flash reduction furnace, an electric melting furnace, and exhaust gas post-treatment equipment.

- The equipment includes a preheating/prereduction device, a dust removal and purification device and a heat exchanger connected by pipelines in sequence;

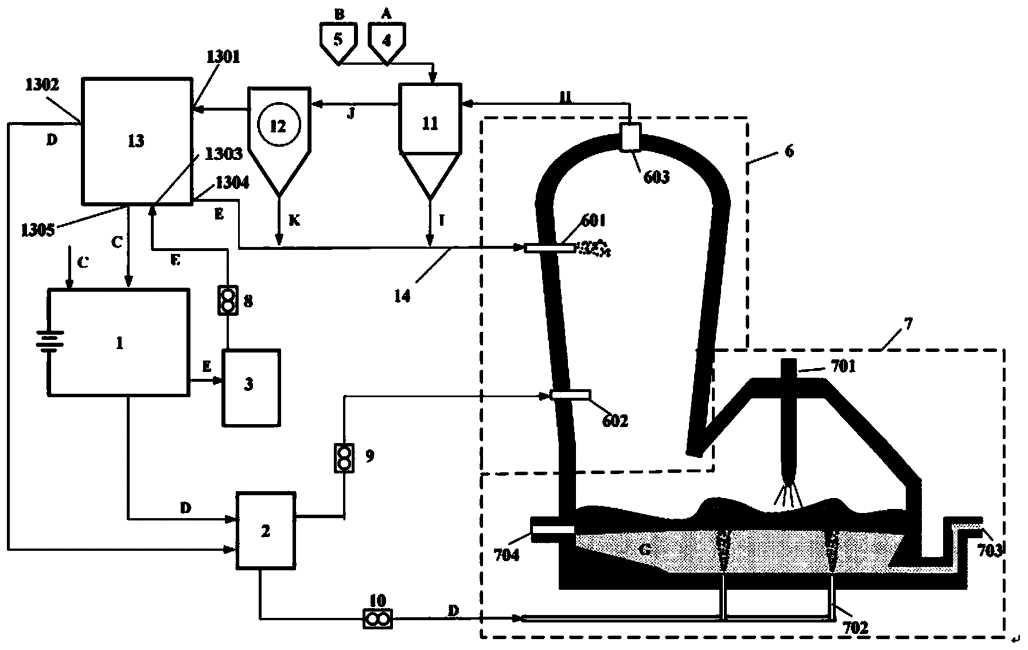

Figure 1 is a schematic diagram of the system structure of the present invention; Reference signs: 1- Hydrogen production reactor by electrolysis of water, 2- Hydrogen storage tank, 3- Oxygen storage tank, 4- Iron ore powder feed hopper, 5- Flux powder feed hopper, 6- Cyclone flash reduction furnace, 7-Electric melting furnace, 8-cyclone flash reduction furnace oxygen flow control valve, 9-cyclone flash reduction furnace hydrogen flow control valve, 10-electric melting furnace hydrogen flow control valve, 11-preheating/pre-reduction device , 12-Dust removal and purification device, 13-heat exchanger, 14-feeding pipeline; Among them, the cyclone flash reduction furnace includes: 601-feeding port, 602-hydrogen nozzle, 603-exhaust gas outlet; Among them, the electric melting furnace includes: 701-electrode, 702-bottom blowing element, 703-steel outlet, 704-slag outlet; Among them, the heat exchanger includes, 1301-first air inlet, 1302-first air outlet, 1303-second air inlet, 1304-second air outlet, 1305-condensate water outlet;

A-iron ore powder, B-flux powder, C-liquid water, D-hydrogen, E-oxygen, F-slag, G-molten steel, H-tail gas, I-preheating/pre-reduction powder, J-cooling Dust-containing exhaust gas, K-dust removal;

Problem

- The emissions, predominantly carbon dioxide (CO2), in iron and steel production primarily stem from the combustion of fossil fuels.

- the current smelting reduction/direct steelmaking method still relies on coal-based reductants, and the reduction process emits large amounts of greenhouse gases and pollutants.

Solution

- The energy required by the entire system (including water electrolysis device, electric melting furnace) comes from electric energy, and the electric energy generation method can be any non-fossil fuel power generation such as nuclear energy, solar energy, and hydraulic power.

- The process completely utilizes electric energy for smelting without relying on fossil fuel, completely uses hydrogen as a reducing agent, and has no pollutant emission in the process.

Application & Advantages

- The described system and process offer advanced features such as the use of electric energy, no pollutant emissions, cyclic raw material utilization, clean smelting, high metallization rates, and no CO2 emissions. These features collectively contribute to a more sustainable and environmentally friendly approach to smelting.

- The invention makes full use of fine ore resources, gets rid of coking, sintering, pelletizing and other processes, and does not require converter decarburization, thereby simplifies the steelmaking process. Hence, it may reduce the cost requirement for steel plant.

- In the present invention, the hydrogen is returned to the cyclone flash reduction furnace, and the condensed water is returned to the electrolyzed water to produce hydrogen.

About Effectual Services

Effectual Services is an award-winning Intellectual Property (IP) management advisory & consulting firm offering IP intelligence to Fortune 500 companies, law firms, research institutes and universities, and venture capital firms/PE firms, globally. Through research & intelligence we help our clients in taking critical business decisions backed with credible data sources, which in turn helps them achieve their organisational goals, foster innovation and achieve milestones within timelines while optimising costs.

We are one of the largest IP & business intelligence providers, globally serving clients for over a decade now. Our multidisciplinary teams of subject matter experts have deep knowledge of best practices across industries, are adept with benchmarking quality standards and use a combination of human and machine intellect to deliver quality projects. Having a global footprint in over 5 countries helps us to bridge boundaries and work seamlessly across multiple time zones, thus living to the core of our philosophy - Innovation is global, so are we !!!

Related Resources:

Decarbonisation in Steel Manufacturing: Overview

Decarbonisation in Steel Manufacturing: Solvent-Based Carbon Capture

Solutions Driving Innovation & Intelligence

Enabling Fortune 500's, R&D Giants, Law firms, Universities, Research institutes & SME's Around The Globe Gather Intelligence That

Protects and Nurtures Innovation Through a Team of 250+ Techno Legal Professionals.