Decarbonisation in Steel Manufacturing: Solvent-Based Carbon Capture

Example -1: CDRMax® - Solvent-Based Carbon Capture

CDRMax® - Solvent-based carbon capture which is a decarbonisation technology focuses smart carbon usage pathway. The CO2 capture technology offering advanced features such as reduced capital and operating costs, a well-tested track record in numerous facilities globally, faster project turnaround times, suitability for mid-to-large capacities, and significant cost savings in terms of CAPEX and OPEX. The technology an attractive solution for reducing carbon emissions in industries like steel, cement, refinery, waste to energy, and biogas.

US20210138391A1 Publication Year: 2021

Technology Summary

- The CDRMax™ process utilizes our CO2 capture technology, proprietary solvent, process equipment, and advanced heat integration to significantly reduce both capital and operating costs.

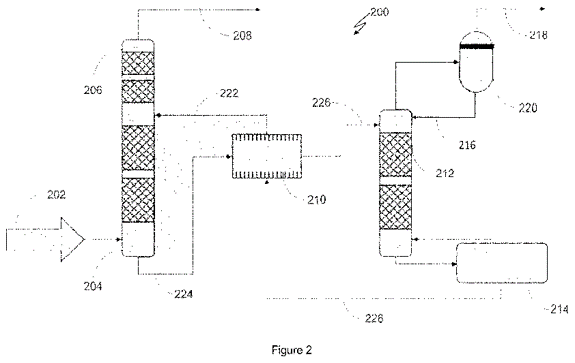

- A system used to capture CO2 comprises an absorber packed column or a rotary packed bed absorber(RPB), and solvent. The solvent may come into contact with the flue gas 202. The rotation of the RPB absorber 204 may increase the mixing between the flue gas 202 and the solvent, and may lead to an improved mass transfer of CO2 from the flue gas 202 to liquid solvent.

- The solvent is a CO2 rich intensified solvent (Ex. CDRMax as sold by CarbonClean) has the following formulation: from 15 to 25 wt. % 2-amino-2-methyl propanol (CAS number 124-68-5); from 15 to 25 wt. % 1-(2-ethylamino) piperazine (CAS number 140-31-8); from 1 to 3 wt. % 2-methylamino-2-methyl propanol (CAS number 27646-80-6); from 0.1 to 1 wt. % potassium carbonate (584-529-3); and, the balance being deionised water (CAS number 7732-18-5).

Advanced Feature and Application of CDRMax

- Reduce both capital and operating costs.

- Well-tested and proven in 44 facilities around the globe.

- Carbon capture process equipment is well understood by engineering contractors, enabling fast project turnarounds in shorter time frame.

- Suitable for mid-to-large capacities.

- CDRMax™ has been proven to provide a 20% CAPEX reduction compared to other available solutions.

- CDRMax™ reduces OPEX by 30-40% compared to other available solutions.

- CO2 capture technology is designed specifically for hard to abate industries, including steel, cement, refinery, waste to energy and biogas.

Product/Commercial Technology

Carbon Clean has recently designed and commissioned India’s first blast furnace carbon capture plant with Tata Steel to capture 5 tonnes of CO2 per day. CycloneCC™ is a breakthrough combination of two technologies: Carbon Clean's advanced, proprietary APBS-CDRMax® solvent and a novel process technology called rotating packed beds (RPB). This integrated solution reduces costs up to 50% with a 10 times smaller footprint, making it the optimal solution for decarbonising the steel industry.

Product Summary

The CDRMax™ process captures carbon dioxide (CO2) from the industrial flue gases or off-gases emitted from power plants, boilers, kilns and chemical facilities. CDRMax™ can be used with source gases that contain CO2 concentrations between 3% and 25% by volume. The process produces CO2 with purities ranging from 95% to 99%, which can then be sold, re-used, or sequestered. The CDRMax™ process utilises our CO2 capture technology, proprietary solvent, process equipment, and advanced heat integration to significantly reduce both capital and operating costs.

Decarbonisation Technology and Application

Desorption Rate of CO2 in a Solvent Measured as a Function of Time and Temperature

Test Method

Process simulations were performed using Pro Treat® to determine the extent of CO2 stripping that occurs when a conventional steam reboiler is used to regenerate the CDRMax solvent samples at similar temperatures and pressures ( 90 ° C. and 0 bar ) as used when a microwave regeneration unit is used as the reboiler.

Results

The efficiency of the conventional reboiler for removing CO , from the CDRMax solvent is shown in Table 3. A conventional stripper operating at 90 ° C. removed 7.3 % of the CO2 from the CDRMax solvent with a rich loading of 2.18 mol L - 1 . Comparable stripping conditions ( 90 ° C. and 2.20 mol L- rich solvent loading ) by microwave irradiation resulted in 57.8 % of the CO2 being stripped from CDRMax solvent ( example 1 ) .

Conclusion

The results show a significant increase in efficiency compared to a conventional steam reboiler process. Comparing the results from samples E and F shows that a higher initial CO2 loading of the rich solvent resulted in a greater CO2, stripping. Additionally comparing samples F and G , a higher reboiler temperature increased the CO2 removed from the solvent.

Problem

Need for a more efficient method of regenerating a solvent after the solvent has become a CO2 rich solvent in system.

The reduction of the temperature required to remove CO2 from the solvent. The reboiler 114, in the example above, typically operates at a temperature of from 110 to 120° C. Such a high temperature causes solvent degradation as well as increasing the cost of the method.

Solution

Compared to a conventional reboiler, at least one advantage of the system of the present invention is the reduction in temperature required to separate the solvent and CO2 (i.e. to regenerate CO2 rich solvent from CO2 lean solvent). Such a reduction in temperature increases efficiency by reducing the energy required regenerate CO2 rich solvent from CO2 lean solvent and mitigates solvent degradation over process cycles.

Using multiple RPB apparatuses in the system may reduce capital cost by mounting as the RPB, absorber, water wash, acid wash, and stripper on a single shaft.

Application & Advantages

- CDRMax™ is a highly efficient and cost-effective carbon capture technology designed for hard-to-abate industries such as steel, cement, refinery, waste to energy, and biogas. With a proven track record in 44 global facilities.

- Engineering contractors are familiar with CDRMax™ process equipment, enabling swift project turnarounds within shorter time frames.

- CDRMax™ provides a comprehensive carbon capture solution for challenging industries, delivering both economic and environmental benefits. Its well-tested performance, cost reductions, and suitability for diverse sectors make it an appealing choice in the pursuit of reducing carbon emissions.

Company Information

Carbon Clean is a global leader in cost-effective CO2 capture technology and services. The company’s patented technology significantly reduces the costs and environmental impacts of CO2 separation when compared to existing techniques.

Highlights

Key People: Aniruddha Sharma Co-founder & CEO

Foundation Year: 2009

Industry: Environment

Location: 2 Eastbourne Ter, London, Essex, W2 6LG, United Kingdom

No. of Employees: 42 Employees

Revenue: <$31.8 Million

Type of Organization: Private

Website: www.carbonclean.com

Technology Information

Carbon Clean Solutions' notable advancements is their efficient CO2 capture technology. Their solutions have been successfully implemented in a wide range of industrial applications, including power plants, steel mills, cement factories, and refineries.

The company's proprietary technology is based on advanced solvent-based absorption processes. These processes enable the efficient capture and separation of CO2 from flue gas emissions. Carbon Clean Solutions' technologies have been extensively tested and validated, demonstrating their effectiveness and reliability in real-world applications.

Carbon Clean Solutions prioritizes cost-effectiveness and scalability. Their solutions are designed to provide economic benefits to their customers, with optimized capital and operating costs. This makes their carbon capture technology a viable option for both large-scale industrial facilities and smaller operations.

Recent News

- Leading carbon capture solutions provider, Carbon Clean, has announced the award of a new contract to global engineering experts, KBR, for the detailed design of a carbon capture plant for Ørsted's FlagshipONE project in Sweden. Source

- Carbon Clean’s technology is being demonstrated at Tata Steel’s Jamshedpur steel plant in India, capturing 5 tonnes of CO2 per day. The modular skid mounted unit captures CO2 directly from the blast furnace gas and makes it available for onsite reuse in a variety of applications. Source

About Effectual Services

Effectual Services is an award-winning Intellectual Property (IP) management advisory & consulting firm offering IP intelligence to Fortune 500 companies, law firms, research institutes and universities, and venture capital firms/PE firms, globally. Through research & intelligence we help our clients in taking critical business decisions backed with credible data sources, which in turn helps them achieve their organisational goals, foster innovation and achieve milestones within timelines while optimising costs.

We are one of the largest IP & business intelligence providers, globally serving clients for over a decade now. Our multidisciplinary teams of subject matter experts have deep knowledge of best practices across industries, are adept with benchmarking quality standards and use a combination of human and machine intellect to deliver quality projects. Having a global footprint in over 5 countries helps us to bridge boundaries and work seamlessly across multiple time zones, thus living to the core of our philosophy - Innovation is global, so are we !!!

Related Resource: Decarbonisation in Steel Manufacturing: Overview

Solutions Driving Innovation & Intelligence

Enabling Fortune 500's, R&D Giants, Law firms, Universities, Research institutes & SME's Around The Globe Gather Intelligence That

Protects and Nurtures Innovation Through a Team of 250+ Techno Legal Professionals.