Recycling of Composite Materials: Tech Insights & Key Players

Chemical recycling of glass fiber reinforced epoxy resin cured with amine using nitric acid

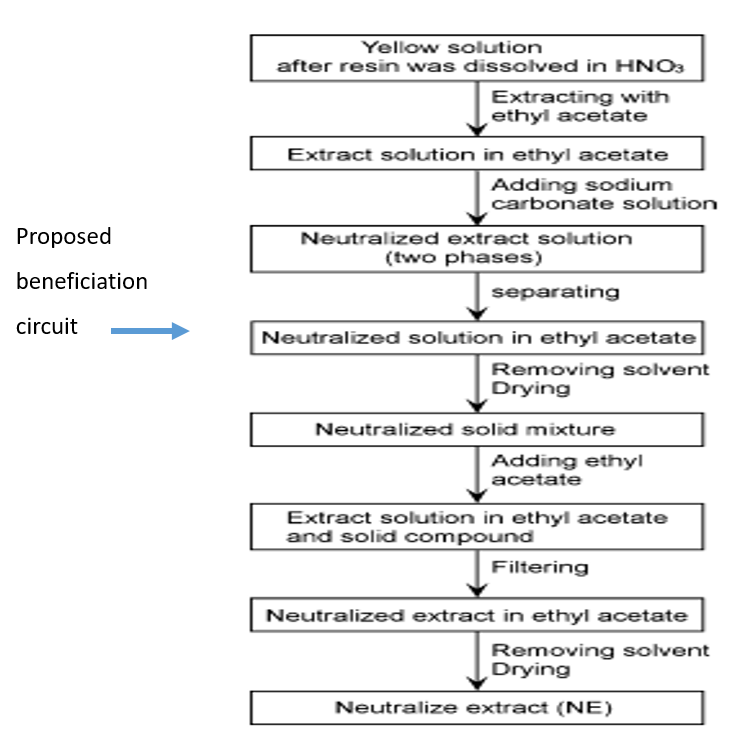

An approach to chemical recycling of amine cured epoxy resin using nitric acid solution has been proposed.

1,8-p-Menthanediamine cured bisphenol F type (BPF/MDA) epoxy resin was decomposed in nitric acid solution, and then the decomposed product was repolymerized with original resin. Applicability of the proposed approach to glass fiber reinforced bisphenol F type epoxy resin cured with diamino diphenyl methane (DDM) was investigated.

Proposed concept:

It was concluded that the approach was applicable to BPF/DDM epoxy resin, and potentially to all of amine cured epoxy resin. Flexural strength of the recycled resin was higher than that of virgin resin until the content of the neutralized extract, which was available from degradation of BPF/DDM epoxy resin, was not more than 30 wt% of the original resin. The reinforcement of glass fiber could be separated and recovered. The existence of the reinforcement did not affect decomposition the matrix.

Further remarks:

- The proposed chemical approach to recycling BPF/MDA epoxy resin was successfully applied to recycle glass fiber reinforced BPF/DDM epoxy resin.

- The GFRP was firstly immersed in nitric acid solution, with the matrix decomposed and glass fiber separated and recovered. And then the decomposed product of extract was collected and neutralized.

- The reinforcement of glass fiber could be separated and recovered from GFRP after matrix of GFRP was decomposed in nitric acid solution.

Recycling of wood fiber-reinforced HDPE by multiple reprocessing

The mechanical recycling of high-density polyethylene (HDPE) reinforced with wood fiber was studied by means of repeated injection moulding. The change in properties during the recycling was monitored by tensile and flexural tests, Charpy impact tests, differential scanning calorimetry (DSC), thermogravimetric analysis (TGA), FTIR spectroscopy, and by measuring the fiber lengths. Tests were also done where injection moulding was combined with subsequent accelerated thermo-oxidative ageing and thereafter repeated numerous times. The results showed that the HDPE composites were relatively stable toward both the ageing conditions and the repeated injection moulding. The change of the mechanical properties was mainly observed as an increased elongation at max.

Result:

The study of post- consumer recycling corresponds roughly to 10 years of usage and four times of mechanical reprocessing. The composites were relatively unaffected by the accelerated ageing. It can, thus, be concluded that recycling of both the aged and the nonaged HDPE wood flour composites can be done without deteriorating the end-use properties too much, except possibly the tensile strength.

Recycling of waste FRP and corn straw in wood plastic composite

Waste fiber reinforced polymer (FRP) combined with corn straw fiber was recycled and incorporated in wood plastic composite (WPC). The synergistic enhancement effect of glass fiber and corn straw fiber was investigated. The results show that there was a good physical interlocking structure among glass fiber of waste FRP, corn straw fiber and poly(vinyl chloride) (PVC) in WPC, which led to the enhancement of mechanical properties of WPC. With 30 phr (parts per hundreds of resin) waste FRP, the tensile strength and flexural strength of WPC were improved to 24 and 66 MPa, increased by 31% and 23% with respect to starting WPC. This study reveals that waste FRP and corn straw fiber can be good alternative for wood fiber in the production of WPC.

Proposed Method:

PVC(S-700, apparent density of 0.52 2 0.62 g/ml, the corresponding polymerization degree was about 700). Sodium hydroxide (NaOH) was of analytical grade. Corn straw was gotten from countryside of Jinan. WF about 0.2 mm particle size was supplied by the furniture factory of Jinan Shuanglin. After corn stalks were dried, the inner core was stripped out and the skin was shattered into small flake straw by coarse mill. Then the platelet straw was put into a fine powder grinding mill. The aperture size of 80 mesh standard sifter was used to sieve the corn straw. Next, the corn straw fiber was treated with 5% NaOH solution for 48 h. Finally, the wet corn straw fiber was washed to pH 7 and dried at 958C for 24 h. Waste FRP (Rixin company, Dezhou, China) was mechanically crushed. The obtained waste FRP powder thus was separated and collected. It was further grinded by an ultrafine miller and then sieved by 80 mesh standard sifter to obtain the waste powder of an average diameter of 0.18 mm. No surface treatment was further performed on the waste FRP powder.

Conclusion:

Waste FRP and corn straw fiber were recycled to prepare WPC. With the best ratio of raw materials, the tensile strength and flexural strength of WPC were improved to 24 MPa and 66 MPa, increased by 31% and 23% with respect to the WPC without FRP, respectively. The vicat softening temperature of PVC100C30F30 was increased from 91.28C to 94.08C. The water absorption of WPC was decreased with addition of waste FRP. Waste FRP and corn straw fiber are quite promising to be alternative for wood fiber in the production of WPC.

Major Players in Recycling technologies of composite materials

Major Projects in Recycling technologies of composite materials

The FiberEUse Project

FiberEUse is part of a €9.8 million research project that aims to integrate different innovations to improve the profitability of composite recycling and their reuse in value-added products. A new cloud-based model allows for value-chain incorporation, exploration of new markets, analysis of legislative barriers, and lifecycle assessments for diverse reverse logistic operations. Source

Old wind turbine blades could be recycled and reused under plans being developed by Aker Offshore Wind (Lysaker, Norway), Aker Horizons (Norway) and the University of Strathclyde (Scotland). The three organizations have signed a memorandum of understanding (MOU) aimed at driving forward the development of recovery processes for used glass fiber products, including a novel process developed at Strathclyde.

Dr Maurice Collins is leading a team of researchers aiming to develop new, sustainable composite materials as part of a €5.3m EU project. Source

About Effectual

Effectual Services is an award-winning Intellectual Property (IP) management advisory & consulting firm offering IP intelligence to Fortune 500 companies, law firms, research institutes and universities, and venture capital firms/PE firms, globally. Through research & intelligence we help our clients in taking critical business decisions backed with credible data sources, which in turn helps them achieve their organisational goals, foster innovation and achieve milestones within timelines while optimising costs.

We are one of the largest IP & business intelligence providers, globally serving clients for over a decade now. Our multidisciplinary teams of subject matter experts have deep knowledge of best practices across industries, are adept with benchmarking quality standards and use a combination of human and machine intellect to deliver quality projects. Having a global footprint in over 5 countries helps us to bridge boundaries and work seamlessly across multiple time zones, thus living to the core of our philosophy - Innovation is global, so are we !!!

Solutions Driving Innovation & Intelligence

Enabling Fortune 500's, R&D Giants, Law firms, Universities, Research institutes & SME's Around The Globe Gather Intelligence That

Protects and Nurtures Innovation Through a Team of 250+ Techno Legal Professionals.