Enabling Industry 4.0 – Industrial Internet of Things

Prelude

When we considered future industrial technology fifty years ago, we frequently envisioned ever-more-agile robots that had hands and legs to better resemble human dexterity. We were only partially correct, as the growth of the Industrial Internet of Things has demonstrated. Undoubtedly, industrial machinery and robots have advanced in sophistication. However, the real breakthrough has been made possible by the industrial devices' ability to function as a part of a network that is connected, allowing them to exchange real-time data and communicate with central business systems and each other.

A "system of systems" driven by AI and enabled by IIoT can curate, manage, and analyze data across the whole enterprise. This system enables real-time collaboration between humans, machines, and other systems, enabling more robust operations and long-term corporate expansion.

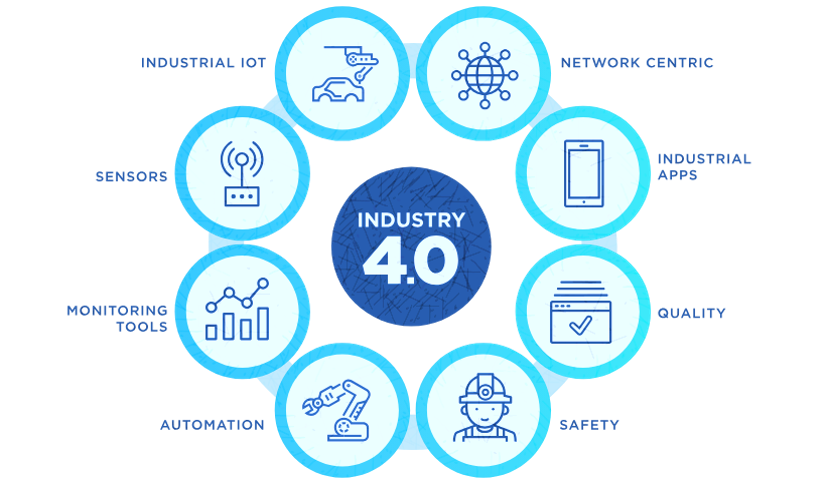

The term IIoT, which stands for "Industrial Internet of Things," describes the deployment of Internet of Things technology—that is, linked equipment, gadgets, and sensors—in industrial settings. The data produced by IIoT devices can be analyzed and used by a contemporary ERP equipped with AI and machine learning capabilities to enhance productivity, efficiency, visibility, and other aspects. Machine-to-machine (M2M) communication and frequent data transmission between the central system and all IIoT-integrated devices are often supported by IIoT networks. Industry 4.0 technologies also heavily rely on IIoT technology.

What is Industrial Internet of Things (IIoT)?

One essential component of Industry 4.0 is the Industrial Internet of Things, or Industrial IoT (IIoT). With the help of IIoT, industrial equipment that have been producing large amounts of data for years can be used more effectively by utilizing real-time analysis and smart machine capabilities. Smart machines are the main force behind IIoT for two reasons. One advantage of smart machines over humans is their ability to capture and evaluate data in real-time. The second is that quick and easy communication of discoveries by intelligent machines facilitates quicker and more precise commercial decision-making.

The application of intelligent sensors, actuators, and other gadgets—like radio frequency identification tags—to improve industrial and manufacturing processes is known as the industrial internet of things, or IIoT. These gadgets are connected via a network to facilitate data gathering, sharing, and analysis. This process's insights contribute to increased dependability and efficiency. IIoT, sometimes referred to as the industrial internet, is utilized in a wide range of sectors, including manufacturing, utilities, oil and gas, and energy management.

IIoT leverages the data generated by dumb machines that have been in industrial settings for years by utilizing real-time analytics and smart machine capabilities. The underlying principle of IIoT is that intelligent robots are superior to humans not only in real-time data capture and analysis, but also in transmitting critical information that can expedite and improve the accuracy of business choices.

Connected sensors and actuators help businesses identify inefficiencies and issues early on, which saves time and money and supports business intelligence initiatives. IIoT specifically has the potential to improve supply chain efficiency overall, traceability of the supply chain, sustainable and green practices, and quality control in the manufacturing sector. IIoT is essential to industrial operations including asset tracking, improved field service, energy management, and predictive maintenance.

How does IIoT infrastructure look?

An intelligent device network, or IIoT, is made up of interconnected devices that monitor, gather, exchange, and analyze data. The components of any industrial IoT ecosystem are as follows:

Devices that are networked and have the ability to sense, communicate, and retain personal data.

Infrastructure for data communications, both public and private.

apps and analytics that turn unprocessed data into useful business information.

Data storage for the IIoT devices' generated data.

Individuals

These intelligent assets and edge devices provide data straight to the data communications infrastructure, where it is transformed into useful information about how a certain piece of equipment is performing. Both predictive maintenance and business process optimization can benefit from this data.

What is the difference between IoT and IIoT?

While cloud platforms, sensors, networking, machine-to-machine communications, and data analytics are among the many technology that the internet of things and IIoT share, their applications differ.

Devices from several verticals, such as agricultural, healthcare, business, consumer, utilities, government, and cities, are connected by IoT systems. IoT technology comprises fitness bands, smart devices, and other applications that, unless anything goes wrong, usually don't result in emergencies.

Conversely, IIoT applications link equipment and machinery in industries including manufacturing, utilities, and oil and gas. In IIoT implementations, system malfunctions and outages may put users in dangerous or even fatal situations. Compared to IoT applications, which are primarily focused on the user, IIoT applications are more concerned with enhancing efficiency, health, or safety.

While IIoT and IoT share many fundamental technological underpinnings, IIoT places a far greater emphasis on automation and efficiency throughout a linked organizational ecosystem rather than on a single, isolated user. Data collection and curation in IIoT networks is merely the start of a more involved process. Artificial intelligence and machine learning must be applied to the data in order to maximize business benefits by delivering precise insights and optimizing workflows and automated tasks. The seamless interaction between human users and these gadgets is essential for the creation of cyber-physical networks that combine the best aspects of technology and human intelligence.

Which industries are using IIoT?

The automotive industry

Industrial robots are used in this business, and IIoT can assist with proactive maintenance and early detection of possible issues to prevent production disruptions. IIoT devices are also used by the automotive sector to gather data from client systems and transfer it to the company's systems. We then use that data to find any maintenance problems.

The industry of agriculture

Industrial sensors gather information on moisture content, nutrients in the soil, and other factors to help farmers grow the best crop possible.

The oil and gas industry

Some oil corporations operate a fleet of self-governing planes that identify possible pipeline issues using thermal and visual imaging. To guarantee safe operations, this data is integrated with information from various kinds of sensors.

Utilities

IIoT is utilized in the metering of gas, water, and electricity in addition to remote monitoring of industrial utility equipment like transformers.

How it works: IIoT technology

An IIoT network needs to be able to store, manage, analyze, and utilize the data that it collects and transmits in order to be effective. It also needs to be able to connect assets and devices to a central system.

IIoT networks depend on the following technologies to achieve this:

IIoT networks require connectivity (including 5G) in order to send and receive the enormous amounts of data that are produced by machines and other devices. Traditionally, the power of Wi-Fi networking has both enabled and limited this. However, 5G and other cellular network advancements are altering this calculation by lowering latency and battery usage while simultaneously expanding capacity to handle bigger data volumes. These features enable a higher number of devices with faster signal transmission and reception, resulting in more effective data processing and extended battery life.

IIoT sensors

Modern industrial gear and equipment usually come with sensors built in. However, IoT gateways like cameras and gauges can also be installed in analog machinery and manufacturing equipment. This enables IIoT assets to sense many environmental factors, such as other objects' proximity, air pressure, humidity, motor speed, fluid levels, and other mechanical variables. Then, all of this data can be processed locally to guide activities in real time, or it can be sent over the cloud for advanced analysis to a central system (like an ERP).

Edge computing and cloud computing power

These two technologies have significantly increased IIoT's usefulness and versatility. IIoT networks can take advantage of a high level of processing power and storage capacity on demand through the cloud. This implies that larger and more complicated data sets can be collected and transmitted by networked devices. Putting systems that can handle and analyze such data on-premise, physically closer to the IIoT network, is known as edge computing. Time-sensitive IIoT data can now be processed in real time because to this reduction in latency and delays. IIoT data can be periodically transferred to the central AI-powered system for more in-depth, non-urgent analysis.

AI and machine learning

Businesses can now process IIoT data with sophisticated and predictive analytics thanks to AI and machine learning technology. Businesses can also benefit from the use of modern databases and machine learning algorithms to handle and interpret complicated, unstructured data as well as different data sets. These solutions enable the analysis of IIoT data in nearly infinite combinations with other forms of data insights, including marketing analytics, weather reports, consumer feedback, and more. Companies can start to gain more complicated and sophisticated insights and learnings to help them compete, save money, and meet customer needs as systems learn over time and as data sets get bigger and more precise.

Cyber-physical system security

IIoT networks are made vulnerable by the same connectivity that makes them possible. Some businesses leave their IoT devices relatively exposed, even when they have strict security and access controls around their databases and central systems. They can function as basement windows in effect, providing complete access through traditional entrance points to a system that is otherwise fairly secure. Thankfully, security technologies and standards are advancing in tandem with IIoT developments. Cross-business security protocols that are properly explained to and followed by each employee and operator, however, frequently fall behind. Any modern organization must prioritize security strategies if they haven't previously.

IIoT applications need dataflow to function as best they can. Businesses utilize a databus to disseminate and handle real-time data in order to support dataflows. The ability of devices and apps to function as a single, cohesive system is made possible by this technology. A databus handles data in motion, whereas a database handles historical data that is at rest. Processes are streamlined and automated using IIoT, increasing efficiency in the workplace. It raises revenue generation, decreases operating expenses, and enhances operational efficiency. Increased automation improves product quality, which helps with predictive maintenance when paired with effective operations.

The likelihood of generating new revenue streams is significantly increased with IIoT. Data insights can reveal how a well-managed business might improve efficiency by addressing hidden inefficiencies.

Newer products or services are developed based on performance or usage statistics. Manufacturers can collaborate with other manufacturers to develop asset-sharing schemes, for instance. This cost-effective resource pooling maximizes available space and manufacturing capacity. In a similar vein, IIoT gadgets can better monitor and control HVAC systems.

IIoT aims to raise quality and production without taxing resources. This is really beneficial for business growth.

Benefits of IIoT and cyber-physical systems

Improved business agility

Real-time data sharing across IIoT devices adds to an intelligence network that continuously collects, examines, and learns from data. This enables companies to react quickly and decisively to opportunities as well as risks. Furthermore, the same devices have the ability to adapt and optimize their automated workflows by receiving instructions based on data analysis in addition to sending data.

Healthier machines

Operational logs and performance data are continuously transmitted by machines and devices within an Internet of Things network. This sensor data is used by AI and machine learning algorithms to obtain important insights regarding predictive and other maintenance needs, which can result in large cost savings. In fact, predictive maintenance "usually reduces machine downtime by 30% to 50% and increases machine life by 20% to 40%," according to McKinsey.

Greater efficiency

Regretfully, when it comes to setting priorities for their operational needs, organizations frequently adopt the mindset of "if it isn't broke." This kind of thinking may cause outdated, ineffective legacy systems to persist longer than necessary. By using advanced analytics on IIoT data, strategies and recommendations for process updates, workflow optimization, and productivity gains are continuously generated.

Smarter inventory management

Customers of today demand ever-greater customization and variety, as well as next-day delivery. This translates into a wider inventory with more unique items and a larger network of smaller, more dispersed warehouses. Supply chain managers (as well as customers) can have real-time visibility into the whereabouts of inventories at all times by connecting geographically dispersed warehouses, inventory, and delivery networks through the usage of IIoT devices. Additionally, for some products, gadgets like additive (3D) printers can lessen a company's reliance on distant producers by enabling them to keep virtual inventories and produce the goods they require locally and on demand.

Safer workers

Injury or strain is a constant risk in any work setting. These days, a lot of companies are using IoT workplace safety equipment to lower this danger. These may employ VR headsets to enable workers combine their sensory experiences with the accuracy of smart devices and machinery, or they could use wearable sensors to convey warnings.

IIoT equipment in manufacturing environments can also be equipped with sensors to track their physical interactions with human counterparts in order to shield them from unanticipated danger or repetitive strain. Over time, these sensors can even be used to inform new, safer workflows.

Improved customer service

IIoT networks incorporate customer experience and input in addition to connecting the machinery and gadgets used by a business. Greater ability to incorporate client comments and preferences into the manufacturing and development of new products, more transparent and personalized logistics, and more frictionless shopping experiences are the outcomes of this integration.

A business strategy that is more robust and competitive is one that engages customers in real time.

Benefits of IIoT in the manufacturing industry

Predictive maintenance

Companies can forecast when a machine requires maintenance by using real-time data produced by IIoT devices. In this manner, the required upkeep can be finished ahead of a failure. This is particularly useful on a production line, where a machine failure could cause a work stoppage and significant expenses. Better operational efficiency can be attained by an organization through proactive maintenance issue resolution.

More efficient field service

By using IIoT technologies, field service professionals can find possible faults in client equipment before they become serious ones, allowing them to address the issues before they have an impact on customers. Field service technicians can also get information from these technologies regarding the items that they need to fix a problem. This guarantees that when on a service call, technicians have the required parts on hand.

Asset tracking

Asset management systems allow manufacturers, suppliers, and customers to monitor the location, status, and condition of goods at any point in the supply chain. If the items are damaged or in danger of being damaged, the system instantly notifies the relevant parties, allowing them to take corrective action either immediately or in advance.

Increased customer satisfaction

Product designers and manufacturers can create better customer-focused product roadmaps when they connect their products to the Internet of Things (IoT) and gather and analyze data about how customers use them.

Improved facility management

Manufacturing equipment is prone to wear and tear, which particular manufacturing conditions might make worse. Vibrations, temperature, and other elements that can result in less-than-ideal working conditions can all be monitored using sensors.

Is IIoT secure?

IIoT devices need to be assessed individually, just like any other linked device. It is quite feasible for a device made by one manufacturer to be secure while another's is not. Nevertheless, gadget makers are placing a higher focus than ever before on security. For instance, end-to-end encryption, multifactor authentication, and the development of unique authorization levels are some security techniques that may be employed in the IIoT.

AT&T, Cisco, General Electric, IBM, and Intel were among the technology corporations that founded the Industrial Internet Consortium (IIC) in 2014. The IIC was renamed the Industry IoT Consortium in 2020. This group prioritizes security, even creating a working group on security, even if its main goal is to hasten the deployment of IIoT and associated technologies. The technology, liaison, marketing, industry, and digital transformation working groups are among the various entities within the IIC.

Risks and challenges of IIoT?

Security is the main danger that comes with using IIoT. Even when they are deployed into production, IIoT devices frequently stick with their default passwords. Likewise, a lot of IIoT devices send data in the form of legible text. An attacker may find it extremely simple to intercept data flowing from an IIoT device under these circumstances. In a similar vein, an intruder may hijack an unsecured IIoT device and utilize it as a springboard to assault further network resources.

The management of devices and security provide significant obstacles for individuals in charge of an organization's IIoT equipment. Adopting an efficient device management strategy becomes more crucial when an organization adds more IIoT devices. More precisely, in order to stop rogue devices from being used, businesses need to be able to positively identify IIoT devices. For operations like replacing a broken device or doing a device refresh, establishing a way to identify each specific device is also essential.

Managing patches is an additional difficulty when using IIoT devices. Periodic firmware updates from device makers are becoming more and more regular. Companies need to be able to quickly verify whether devices are running the most recent firmware and update them as needed. To prevent operations from being disrupted, such a tool must also follow the organization's defined maintenance plan.

IIoT applications and examples

ABB, a power and robotics firm, uses connected sensors to monitor the maintenance needs of its robots and trigger repairs before parts break in a real-world IIoT deployment of smart robotics.

Similarly, in an effort to improve productivity and streamline processes, Airbus, a manufacturer of commercial jetliners, introduced a program known as the factory of the future—digital manufacturing.

In order to decrease errors and improve workplace safety, Airbus equipped workers with wearable technology, such as industrial smart glasses, and integrated sensors into equipment and machines on the shop floor.

Fanuc, a different robotics manufacturer, has employed sensors and cloud-based data analytics to anticipate the impending failure of its robots' components.

By doing this, the plant manager can arrange maintenance at favorable times, cutting expenses and possibly preventing downtime.

The Austrian automaker Magna Steyr uses IIoT to track its assets, such as tools and car parts, and to place automatic orders for additional stock as needed.

IIoT vendors

ABB Ability

ABB is an expert in software, machine intelligence, and connectivity.

Aveva

Early in 2023, Aveva was acquired by Schneider Electric. The company creates platforms for original equipment manufacturers, end users, digital transformation, and AI, as well as IIoT and IoT edge.

Cisco Internet of Things

Cisco provides solutions for edge computing, data control and exchange, network connectivity, and connectivity management.

Fanuc

Fanuc offers industrial IoT solutions by fusing automation, robots, and sophisticated analytics.

GE Predix Platform

Digital industrial applications may be connected, optimized, and scaled with the aid of this IIoT software platform.

Plataine

Plataine is an expert at leveraging AI to produce useful manufacturing insights.

Siemens Insights Hub

Industrial IoT built on AI and sophisticated analytics is provided by Insights Hub.

Future of IIoT

IIoT devices will be crucial to digital transformations, particularly as businesses try to automate their supply chains and production lines. Furthermore, IIoT data will be incorporated into big data analytics as it develops, enabling businesses to recognize changing circumstances instantly and take appropriate action.

Despite the fact that IIoT devices have been available for a while, their actual use is constantly expanding.

As 5G becomes more widely used and more businesses start to see the benefits of IIoT, adoption rates may also shift. The usage of IIoT devices will probably be impacted by 5G in two key ways.

First, real-time data sharing between devices is made feasible by 5G's high throughput and low latency. This was previously limited to situations in which the devices were connected to private networks at high speeds. Smart cities and driverless automobiles are two use cases that this real-time communication may help with. The proliferation of devices that 5G is expected to cause is another way it will impact the adoption of IIoT. Thousands of 5G-enabled devices could be used in industrial activities. Due to 5G's rapid speed and low latency, IIoT devices will probably be used in remote locations where IIoT use was previously impractical due to a lack of high-speed connectivity.

Please feel free to reach out to one of our subject matter experts at info@effectualservices.com

to explore, how we can help you & make the world a better place to live in !!!

Effectual’s IIOT RESEARCH FRAMEWORK is a deep dive into this ecosystem and shall help you understand the intricacies of this nascent innovative domain with insights backed with credible data sources. Some ways we can help include, but not limited to - Performing any previous art or freedom to operate searches to help you better grasp the environment surrounding your invention or business endeavors. If certain methods of IP protection are more appropriate for your technological or business goals, we can help you strategize effectively to plan for future & in making continuous innovation a part of your working model.

Solutions Driving Innovation & Intelligence

Enabling Fortune 500's, R&D Giants, Law firms, Universities, Research institutes & SME's Around The Globe Gather Intelligence That

Protects and Nurtures Innovation Through a Team of 250+ Techno Legal Professionals.